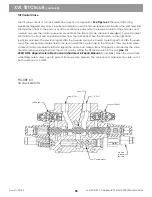

FIGURE 74

AUXILIARY CIRCUIT

The auxiliary valve has two port reliefs and a section compensator.

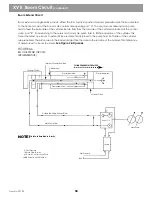

See Figure 75

It also has electrically

triggered end caps for spool shift. Stroke limiters on the end caps control maximum fluid flow. On/off solenoids

on each end cap receive pilot fluid from the pilot feed line and the end cover of the control valve assembly. The

reservoir return for the end caps and solenoid is also through the control valve end cover. When the front end

cap solenoid is energized, the solenoid opens to direct pilot fluid to the front end cap. Fluid will flow from the

front port. When the auxiliary switch (located on the left-hand joystick or on the cab floor, depending on the

machines auxiliary control configuration) is actuated, an electrical signal shifts the solenoid spool. The pilot

signal from the solenoid shifts the valve spool and the compensator meters fluid to the spool. The spool then

routes fluid to the auxiliary hydraulic function. The valve load sense system controls the compensator shift and

signals the pump load sense system.

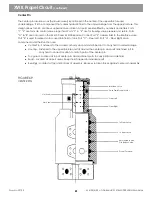

Auxiliary speed is controlled by the stroke limiter in the end cap. The stroke limiter is set to limit maximum flow

out of the work port. When the circuit is stalled while using auxiliary hydraulics, relief valves open to protect the

circuit from excessive pressure. The valve spool allows a maximum flow rate of 40 GPM out of both work ports.

Fluid is routed to the end of the boom through a hose trough. This trough consists of guide plates, a roller,

springs and a carriage; it is located at the rear of the main boom. Normally, two hoses are in this trough. If

optional auxiliary hydraulics are installed, there are four hoses. Lubricating these hoses and guides with a dry

lubricant can extend hose life.

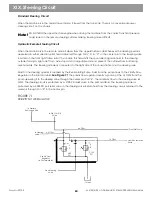

Always refer to instructions for the auxiliary attachments maximum flow rate and maximum working

pressure. If instructions are unclear, contact the attachment manufacturer for more information.

Ouick disconnects at the end of the boom make changing hydraulic attachments easy. When attachments are

not in use, their hoses are unplugged from the auxiliary circuit, rendering the circuit idle. Typical attachments

used on the end of a GRADALL boom requiring auxiliary hydraulics include: hammers, compactors, mower/brush

cutters, augers and blenders.

XXI. Auxiliary Circuit Optional

NOTE!

Form No. 29703

66

To Auxiliary Implement

To Auxiliary Implement

Electric

Solenoid

Auxillary

Control

Valve

Main Pump

Electric

Solenoid

Joy

stick

L.H.

Pilot Pressure

Right

Left

Hydraulic Fluid Path

Simplified for Clarity

NOTE!

NOTE!

Electric switch on top of

L.H. joystick. Some aux.

attachments mount

switch on cob floor.

Содержание XL4000

Страница 2: ......

Страница 73: ......

Страница 76: ... 5MP ...

Страница 145: ......

Страница 146: ......

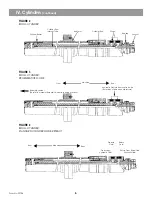

Страница 151: ...From No 296020 2 97 4 FIGURE 4 FIGURE 5 FIGURE 3 IV Saving Charge and Pilot Pressure continued ...

Страница 160: ......

Страница 161: ......

Страница 162: ......

Страница 175: ......

Страница 176: ......

Страница 177: ......

Страница 178: ......

Страница 192: ......

Страница 193: ......

Страница 194: ......

Страница 207: ......

Страница 208: ......

Страница 210: ...500P ...

Страница 229: ......

Страница 230: ......

Страница 245: ......

Страница 246: ......

Страница 247: ......

Страница 248: ......

Страница 265: ......

Страница 266: ......

Страница 267: ......

Страница 268: ......

Страница 280: ......

Страница 281: ......

Страница 282: ......

Страница 297: ......

Страница 298: ......

Страница 299: ......

Страница 300: ......

Страница 301: ......

Страница 302: ......

Страница 303: ......

Страница 304: ......

Страница 305: ...GRADALL h y d r a u l i c e x c a v a t o r s XL 4000 5000 CENTER PIN REBUILD Form No 20026 Part No 2460 4164 ...