This i

nformation is to be used for adjustment and setup of the main and swing pumps. In most situations, the

pumps will not need to have the following settings checked or altered. Consult with GRADALL before altering

pump settings.

All other pressur

es must be checked using the XL 5110 Hydraulic Pressure Setting Manual (Form No. 24627)

before making any checks of pump settings. The procedures in this manual will require the same tools. Additional

gauge hoses — two 7713-3259 hoses and one 7713-4198 union — will be required. These can be removed from

another gauge kit,

or ordered separately.

If any pump adj

ustment screws are altered, a new seal cap must be installed. Two sizes of caps are used on

GRADALL XL SERIES excavators. Small blue caps are part number 8093-4459; and large blue caps are part number

8093-4460.

This proc

edure covers XL 5110 machines. Each step will note pressures for specific models. If you are servicing a

machine

other than what is listed, please consult with GRADALL for correct settings.

The Swing Pump Begin Point adjustment controls the point that the swing pump comes on stroke in relation to

joystick input pressure. This should only be adjusted if the machine exhibits problems with swing start, or pulsing

while swinging. This also should be adjusted if someone has tampered with the swing pump begin point screws.

Reseal swing pump begin point screws after adjustment.

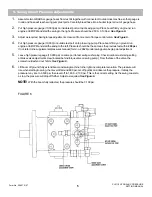

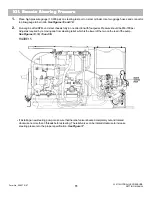

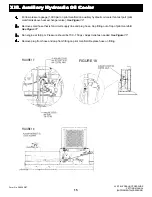

Assemble two sets of GRADALL gauge hoses from test kit with a connector. On one set of hoses, place a

10,000 psi gauge. Place a 1,000 psi gauge on the other set. Route both sets of hoses across machine so that

both gauges may be laid on the cradle stop at the front of the frame on the left hand side of the cab. Connect the

hose with the high pressure gauge to the outside test port of the swing pump. Remove the plug that is between

the two high pressure test ports. Install adapter (8656-1311) and test port (7713-3089) in place of the plug.

Attach the hose with the low pressure gauge to this added test port. Start the engine and allow it to run at a

low RPM. Go to the gauge end of the hoses, remove the gauges and allow air to bleed out of the hoses.

Catch any oil in an approved container to prevent oil spills. Aher air is purged, reinstall gauges and clean up

any spillage.

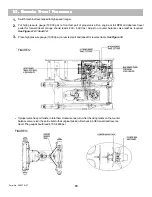

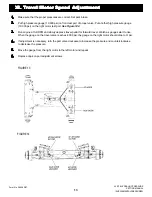

Place tool firmly on ground, run engine at full RPM, then meter the right hand joystick for right hand swing.

Observe the gauges for when the low pressure gauge rises to 90 psi, swing pressure on the high pressure gauge

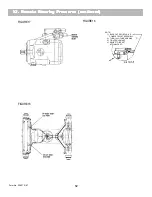

should rise to 500 - 550 psi. This is the swing begin point. Adjust the inside screw on the pump control to achieve

proper begin pressure.

See Figure 1.

NO

NO

NO

NO

NOTE!

TE!

TE!

TE!

TE!

This adjustment affects swing begin pressure; it does not affect the pilot signal to the pump.

Move hose with high pressure gauge to the inside test port, bleed air from this hose aher moving it. Repeat this

procedure, except use left hand swing. Adjustments are made to the outside adjustment screw.

See Fgure 1.

After adjustments are made, check operation and metering of swing circuit. Also check the maximum torque setting.

See XL 5110 Hydraulic Pressure Setting Manual.

I. Pump Adjustment and Setup

I. Pump Adjustment and Setup

I. Pump Adjustment and Setup

I. Pump Adjustment and Setup

I. Pump Adjustment and Setup

II.

II.

II.

II.

II. Swing Pump Be

Swing Pump Be

Swing Pump Be

Swing Pump Be

Swing Pump Begin P

gin P

gin P

gin P

gin Point

oint

oint

oint

oint

1.

1.

1.

1.

1.

2.

2.

2.

2.

2.

4.

4.

4.

4.

4.

3.

3.

3.

3.

3.

Form No. 29626 2/97

XL 5110 HYDRAULIC PRESSURE

SETTING MANUAL

(SUPPLEMENTAL PRESSURES)

1

Содержание XL4000

Страница 2: ......

Страница 73: ......

Страница 76: ... 5MP ...

Страница 145: ......

Страница 146: ......

Страница 151: ...From No 296020 2 97 4 FIGURE 4 FIGURE 5 FIGURE 3 IV Saving Charge and Pilot Pressure continued ...

Страница 160: ......

Страница 161: ......

Страница 162: ......

Страница 175: ......

Страница 176: ......

Страница 177: ......

Страница 178: ......

Страница 192: ......

Страница 193: ......

Страница 194: ......

Страница 207: ......

Страница 208: ......

Страница 210: ...500P ...

Страница 229: ......

Страница 230: ......

Страница 245: ......

Страница 246: ......

Страница 247: ......

Страница 248: ......

Страница 265: ......

Страница 266: ......

Страница 267: ......

Страница 268: ......

Страница 280: ......

Страница 281: ......

Страница 282: ......

Страница 297: ......

Страница 298: ......

Страница 299: ......

Страница 300: ......

Страница 301: ......

Страница 302: ......

Страница 303: ......

Страница 304: ......

Страница 305: ...GRADALL h y d r a u l i c e x c a v a t o r s XL 4000 5000 CENTER PIN REBUILD Form No 20026 Part No 2460 4164 ...