Form No. 29625 2/97

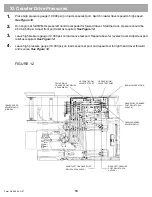

Use two high pressure gauges (10,000 psi) on test ports on top of torque valve on swing pump. Put low pressure

gauge (1,000 psi) on upper test port of pilot charge valve assembly.

See Figure 8.

Start engine and run at full RPM. Swing charge pump pressure should be 380 - 420 psi. Adust as

required (see hydraulic testing and adjusting manual).

When charge pressure is correct, continue to run engine at full RPM. The two high pressure gauges should be

reading equal pressure on each. Correct pressure should be near charge pressure, but not higher.

If gauges above are not balanced, adjust swash plate centering screw (located on inner end cap of stroking

piston housing) until gauges are balanced.

See Figure 8.

If finer adjustment is needed, use two low pressure gauges (1,000 psi) after balancing stroking piston with high

pressure gauges.

CAUTION

Do not actuate swing as gauges will be destroyed.

Figure 8

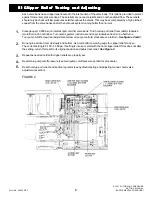

VI. Swing Pump Centering (Mechanical)

VI. Swing Pump Centering (Mechanical)

VI. Swing Pump Centering (Mechanical)

VI. Swing Pump Centering (Mechanical)

VI. Swing Pump Centering (Mechanical)

The swing has adjustments for mechanical centering of the swash plate. This adjustment should be made

with the bucket firmly on the ground and all controls in neutral.

1.

2.

3.

4.

5.

8

Содержание XL4000

Страница 2: ......

Страница 73: ......

Страница 76: ... 5MP ...

Страница 145: ......

Страница 146: ......

Страница 151: ...From No 296020 2 97 4 FIGURE 4 FIGURE 5 FIGURE 3 IV Saving Charge and Pilot Pressure continued ...

Страница 160: ......

Страница 161: ......

Страница 162: ......

Страница 175: ......

Страница 176: ......

Страница 177: ......

Страница 178: ......

Страница 192: ......

Страница 193: ......

Страница 194: ......

Страница 207: ......

Страница 208: ......

Страница 210: ...500P ...

Страница 229: ......

Страница 230: ......

Страница 245: ......

Страница 246: ......

Страница 247: ......

Страница 248: ......

Страница 265: ......

Страница 266: ......

Страница 267: ......

Страница 268: ......

Страница 280: ......

Страница 281: ......

Страница 282: ......

Страница 297: ......

Страница 298: ......

Страница 299: ......

Страница 300: ......

Страница 301: ......

Страница 302: ......

Страница 303: ......

Страница 304: ......

Страница 305: ...GRADALL h y d r a u l i c e x c a v a t o r s XL 4000 5000 CENTER PIN REBUILD Form No 20026 Part No 2460 4164 ...