VIII. Hoist Accumulator

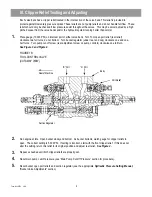

On XL 4200 and XL 5200 machines only, an accumulator is added to the cylinder barrel side of the hoist circuit,

(rear valve port). This accumulator located above the control valves,

See Figure 8,

dampens the hoist bounce

that can occur on crawler-mounted machines. If an operator feels or suspects excessive boom hoist bounce, it will

be necessary to check the accumulator charge.

A simple test for hoist bounce is to raise the boom from the ground to level with the engine at full RPM. As the

boom reaches level, quickly return the joystick to Neutral and observe the bounce of the boom. The standard is

three noticeable bounces. If it seems to have more, check the accumulator charge.

Set the boom firmly on the ground and shut the engine off.

Use a hose from the gauge kit to relieve pressure in the hoist circuit. Catch the waste oil in a proper container.

Remove the accumulator from its clamps and remove the end cap. Screw on an accumulator test port and

observe recharge pressure. It should be 1,200 PSI. Replace or recharge the accumulator as needed. Then properly

reinstall the accumulator on the machine.

When recharging the accumulator, use dry nitrogen only. Use of any other type of

gas can be very dangerous and could cause injury or death. Use only experienced

qualified personnel to remove, recharge and replace the accumulator.

FIGURE 8

ACCUMULATOR

!

DANGER

1.

2.

3.

XL 4000/XL 5000 SERIES

HYDRAULIC PRESSURE SETTING MANUAL

(Supplemental Pressures)

Form No. 29705 3/99

13

Содержание XL4000

Страница 2: ......

Страница 73: ......

Страница 76: ... 5MP ...

Страница 145: ......

Страница 146: ......

Страница 151: ...From No 296020 2 97 4 FIGURE 4 FIGURE 5 FIGURE 3 IV Saving Charge and Pilot Pressure continued ...

Страница 160: ......

Страница 161: ......

Страница 162: ......

Страница 175: ......

Страница 176: ......

Страница 177: ......

Страница 178: ......

Страница 192: ......

Страница 193: ......

Страница 194: ......

Страница 207: ......

Страница 208: ......

Страница 210: ...500P ...

Страница 229: ......

Страница 230: ......

Страница 245: ......

Страница 246: ......

Страница 247: ......

Страница 248: ......

Страница 265: ......

Страница 266: ......

Страница 267: ......

Страница 268: ......

Страница 280: ......

Страница 281: ......

Страница 282: ......

Страница 297: ......

Страница 298: ......

Страница 299: ......

Страница 300: ......

Страница 301: ......

Страница 302: ......

Страница 303: ......

Страница 304: ......

Страница 305: ...GRADALL h y d r a u l i c e x c a v a t o r s XL 4000 5000 CENTER PIN REBUILD Form No 20026 Part No 2460 4164 ...