Form No. 29703

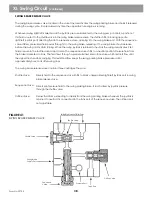

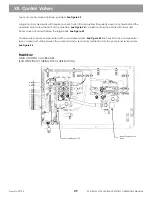

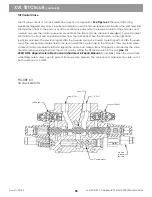

Load Sense

Cavity

Spool

Port Relief

B Part

A Part

Body

Port Relief

Tank Cavity

(2 Places)

Piloted

End Cap

Stroke Limiter (Fixed)

Retainer

Spring

Load Sense

Section

Regulator

Stroke Limiter

(Adjustable)

Load Sense

Port

Pump Supply

Cavity

Spring

Compensator

FIGURE 46

VALVE SECTION (TYPICAL)

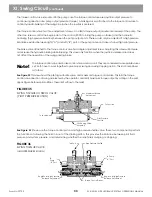

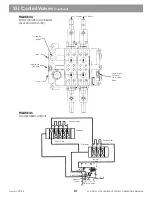

From the valve pressure cavity to the valve spool, the compensator works to allow a constant pressure drop.

See

Figure 44

It also functions as a load check until the pump flow overcomes the circuit pressure and prevents high

pressure in the valve bank from reaching the valve spool in neutral.

See Figure 45

It is designed to meter only

needed fluid to the valve spool while operating.

See Figure 46

Primary shuttles read work port pressure and

signal the compensator. This signal also goes to secondary shuttles and to the pump load sense circuit.

See

Figure 47 The highest pressure work port signals the pump. The diverter valve has no shuttles.

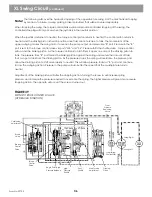

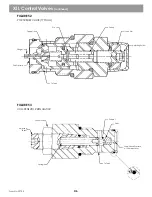

Using a special compensator, the diverter valve sends excess fluid between valve banks. A shuttle in the diverter

compensator determines which is the higher pressure valve bank. The bucket and hoist valve bank has priority on

fluid from one pump section. In low flow conditions, the diverter forces fluid from one pump section into the

bucket and hoist bank. The diverter meters fluid from the two pump sections to match flow requirements in each

valve bank. It is possible, through the diverter, for both pump sections to be used to feed a single valve bank.

Clipper reliefs set at 5,100 PSI protect both valve bank inlets from pressure spikes.

See Figure 48

All valve section

work ports have port reliefs. These reliefs are internally piloted and will function as anti-cavitation checks when port

pressure drops below reservoir return pressure.

See Figure 49

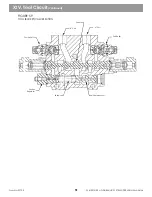

Bucket, hoist and boom valves have pressure regulators in each compensator located below the rear end cap of

each valve.

See Figure 50

They are simple reliefs that open at a preset pressure to enable the compensator to

stop additional oil from getting to the valve spool (sufficient oil will be metered past the compensator to maintain

pressure in the function). This prevents oil from going over the reliefs and makes oil available to other functions

when a regulated function is stalled.

XII. Control Valves

(continued)

42

Содержание XL4000

Страница 2: ......

Страница 73: ......

Страница 76: ... 5MP ...

Страница 145: ......

Страница 146: ......

Страница 151: ...From No 296020 2 97 4 FIGURE 4 FIGURE 5 FIGURE 3 IV Saving Charge and Pilot Pressure continued ...

Страница 160: ......

Страница 161: ......

Страница 162: ......

Страница 175: ......

Страница 176: ......

Страница 177: ......

Страница 178: ......

Страница 192: ......

Страница 193: ......

Страница 194: ......

Страница 207: ......

Страница 208: ......

Страница 210: ...500P ...

Страница 229: ......

Страница 230: ......

Страница 245: ......

Страница 246: ......

Страница 247: ......

Страница 248: ......

Страница 265: ......

Страница 266: ......

Страница 267: ......

Страница 268: ......

Страница 280: ......

Страница 281: ......

Страница 282: ......

Страница 297: ......

Страница 298: ......

Страница 299: ......

Страница 300: ......

Страница 301: ......

Страница 302: ......

Страница 303: ......

Страница 304: ......

Страница 305: ...GRADALL h y d r a u l i c e x c a v a t o r s XL 4000 5000 CENTER PIN REBUILD Form No 20026 Part No 2460 4164 ...