V. Reservoir

Reservoir

The hydraulic reservoir is located at the rear of the upperstructure frame, behind the boom. It is a major

component of the hydraulic system incorporating many design features necessary for correct hydraulic

performance. These features are:

Storage Capacity:

The reservoir is correctly sized to provide a sufficient volume of hydraulic fluid to allow all circuits to fully cycle and

still maintain a correct volume of hydraulic fluid to prevent pump cavitation.

Capacity Checks:

Sight gauges and an electrical indicator monitor fluid levels in the reservoir.

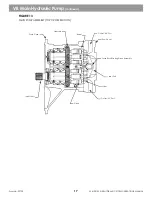

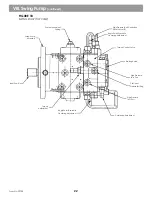

See Figure 8 & Figure 9

Heat Dissipation:

The external reservoir surface assists in heat dissipation from hot hydraulic fluid. There is a fluid temperature

indicator located in the reservoir.

See Figure 8 & Figure 9

This indicator warns of high fluid temperature at the

moniter in the operators cab.

Turbulence Control:

Internal baffles welded in the reservoir reduces foaming by controlling hydraulic fluid turbulence. This allows

entrapped air to dissapate from the hydraulic fluid.

Accessabillity:

Access covers are designed into the reservoir. These allow entrance into the internal areas to facilitate cleaning of

normal sediment build-up.

Air Breather:

A pressurized breather vents air to the atmosphere once it exceeds 10 PSI.

See Figure 10

The reservoir is

pressurized by the machine air system. The reservoir pressure is set of 6-8 PSI. This forces hydraulic fluid into the

pump supply lines. An electrical pressure switch located on the pump suction tube warns of low air pressure at the

monitor in the operators cab.

Drainage:

Fluid drainage plugs in the reservoir bottom are provided for routine maintenance.

Return Filter:

The reservoir houses a 10 micron hydraulic fluid return filter. Hydraulic fluid passes through this filter before it

enters the reservoir. This filter assembly includes a magnet, a 15 PSI. bypass valve, and a removable cover for

ease of service. Bypass condition is indicated via an electrical switch on the dump tube from the control valves.

Suction Screen:

Filtered hydraulic fluid supplied to the pumps leaves the reservoir through the outlet port. Large contaminants are

prevented from entering the pump supply circuit by a 100 mesh suction screen (filter) located inside the reservoir

on the outlet line to the pump.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10

Form No. 29703

Содержание XL4000

Страница 2: ......

Страница 73: ......

Страница 76: ... 5MP ...

Страница 145: ......

Страница 146: ......

Страница 151: ...From No 296020 2 97 4 FIGURE 4 FIGURE 5 FIGURE 3 IV Saving Charge and Pilot Pressure continued ...

Страница 160: ......

Страница 161: ......

Страница 162: ......

Страница 175: ......

Страница 176: ......

Страница 177: ......

Страница 178: ......

Страница 192: ......

Страница 193: ......

Страница 194: ......

Страница 207: ......

Страница 208: ......

Страница 210: ...500P ...

Страница 229: ......

Страница 230: ......

Страница 245: ......

Страница 246: ......

Страница 247: ......

Страница 248: ......

Страница 265: ......

Страница 266: ......

Страница 267: ......

Страница 268: ......

Страница 280: ......

Страница 281: ......

Страница 282: ......

Страница 297: ......

Страница 298: ......

Страница 299: ......

Страница 300: ......

Страница 301: ......

Страница 302: ......

Страница 303: ......

Страница 304: ......

Страница 305: ...GRADALL h y d r a u l i c e x c a v a t o r s XL 4000 5000 CENTER PIN REBUILD Form No 20026 Part No 2460 4164 ...