Form No. 20026 XL 4000/5000 Center Pin Rebuild

Part No. 2460-4164

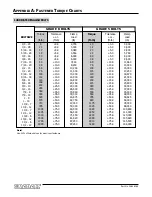

Note!

To check Gradall torque values, set the

torque wrench at 95% of rated torque value

and check the fastener. If the torque

wrench releases before the fastener

moves, assume that fastener torque is

correct. When setting Gradall torque val-

ues, use values given on the chart, not

exceeding allowances.

M

ETRIC

F

ASTENERS

Note!

Use 50% of listed values for aluminum fasteners.

CLASS 4.6

CLASS 8.8

CLASS 9.8

CLASS 10.9

NOMINAL

SIZE

M 2.0

M 205

M 3.0

M 3.5

M 4.0

M 5.0

M 6.0

M 6.3

M 8.0

M 10.0

M 12.0

M 14.0

M 16.0

M 20.0

M 24.0

M 30.0

M 36.0

M 42.0

Stress

Area

(mm

2

)

2.1

3.4

5.0

6.8

8.8

14.2

20.1

22.6

36.6

58.0

84.3

115.0

157.0

245.0

353.0

561.0

817.0

1120.0

400 Megapascals

Min. Tensile Str.

(Nm)

0.14

0.28

0.51

0.80

1.18

2.39

4.05

4.78

9.84

19.49

33.99

54.10

84.40

164.64

284.66

565.49

988.24

1580.54

(ft.-lb)

0.10

0.21

0.37

0.59

0.87

1.76

2.99

3.53

7.26

14.37

25.07

39.90

62.25

121.43

209.95

417.08

728.89

1165.75

830 Megapascals

Min. Tensile Str.

(Nm)

0.37

0.76

1.35

2.13

3.15

6.36

10.81

12.76

26.25

51.99

90.68

144.32

255.18

439.24

759.43

1508.64

2636.49

4216.66

(ft-lb)

0.27

0.56

1.00

1.57

2.32

4.69

7.97

9.41

19.36

38.35

66.88

106.45

166.08

323.96

560.13

1112.72

1944.58

3110.05

900 Megapascals

Min. Tensile Str.

(Nm)

0.40

0.82

1.47

2.31

3.41

6.90

11.72

13.84

28.46

56.38

98.33

156.49

244.17

476.28

823.48

1635.88

2858.85

4572.29

(ft-lb)

0.30

0.61

1.08

1.70

2.52

5.09

8.65

10.21

20.99

41.58

72.52

115.42

180.09

351.29

607.37

1206.56

2108.58

3372.35

1040 Megapascals

Min. Tensile Str.

(Nm)

0.52

1.06

1.88

2.96

4.38

8.86

15.05

17.77

36.54

72.38

126.25

200.93

313.50

611.52

1057.31

2100.38

3670.62

5870.59

(ft-lb)

0.38

0.78

1.39

2.18

3.23

6.54

11.10

13.11

26.95

53.29

93.12

148.20

231.22

451.03

779.83

1549.16

2707.31

4329.93

(Nm)

0.61

1.24

2.21

3.47

5.14

10.59

17.66

20.84

42.87

84.91

148.10

235.70

367.76

717.36

1240.30

2463.91

4305.92

6886.66

(ft-lb)

0.45

0.92

1.63

2.56

3.79

7.67

13.02

15.37

31.62

62.63

109.23

173.85

271.24

529.10

914.80

1817.29

3175.88

5079.34

CLASS 12.9

1220 Megapascals

Min. Tensile Str.

Содержание XL4000

Страница 2: ......

Страница 73: ......

Страница 76: ... 5MP ...

Страница 145: ......

Страница 146: ......

Страница 151: ...From No 296020 2 97 4 FIGURE 4 FIGURE 5 FIGURE 3 IV Saving Charge and Pilot Pressure continued ...

Страница 160: ......

Страница 161: ......

Страница 162: ......

Страница 175: ......

Страница 176: ......

Страница 177: ......

Страница 178: ......

Страница 192: ......

Страница 193: ......

Страница 194: ......

Страница 207: ......

Страница 208: ......

Страница 210: ...500P ...

Страница 229: ......

Страница 230: ......

Страница 245: ......

Страница 246: ......

Страница 247: ......

Страница 248: ......

Страница 265: ......

Страница 266: ......

Страница 267: ......

Страница 268: ......

Страница 280: ......

Страница 281: ......

Страница 282: ......

Страница 297: ......

Страница 298: ......

Страница 299: ......

Страница 300: ......

Страница 301: ......

Страница 302: ......

Страница 303: ......

Страница 304: ......

Страница 305: ...GRADALL h y d r a u l i c e x c a v a t o r s XL 4000 5000 CENTER PIN REBUILD Form No 20026 Part No 2460 4164 ...