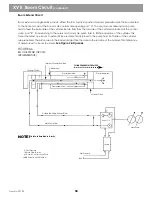

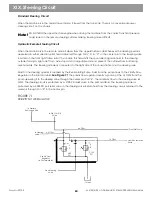

Propel Circuit

The propel circuit of the XL 4100 AND XL 5100 REMOTE CONTROL EXCAVATORS converts hydraulic energy to

mechanical energy for total machine movement. This is accomplished as follows:

Filtered upperstructure hydraulic fluid is supplied to the system by the main and pilot pump circuits

Pilot circuit fluid is directed to main propel control valve forward or reverse end cap

Main propel control valve directs main pump fluid through the center pin to the propel (travel) motor

moving the machine

Machine brakes are released whenever the circuit is pressurized. They are spring-set, hydraulically released.

Motor case drain fluid is returned to the reservoir through the center pin

Return fluid passes through the center pin and control valves to the reservoir

Propel fluid is routed through the center pin to the propel (travel) motor. On the XL 4100s, a Gertler-type motor is

used.

See Figure 64

for XL 4100 Excavators. XL 5100 Excavators use a bent-axis piston motor. See Figure 31 The

motor drives through the truck transmission PTO for remote drive. The air cylinder of the PTO has detents on the

engage/disengage shift rail. After driving through the truck transmission, power is transmitted through the drive

shaft and axles to the rear wheels. On 6x6 units, the front wheels are also driven in remote if the transfer case is

engaged. Orifice check valves on the travel motor maintain back pressure in the motor while travelling to prevent

freewheeling down a grade. An air chamber on the truck chassis keeps the clutch disengaged whenever the

machine is in the remote control mode.

The travel pedal also controls the release of the digging brake system on the undercarriage. A shuttle valve is

connected to each pilot line to the Control valve. When the propel (travel) pedal is engaged, the pilot signal shifts

the propel and shuttle valve. Pilot fluid is directed through the center pin to the chassis interface valve.

See

Figure 68

This pilot signal hydraulically shifts the interface valve which signals the air portion of the valve to

release the digging brakes.

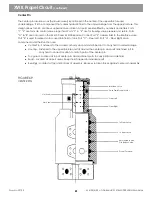

FIGURE 68

PILOT PROPEL CIRCUIT BLOCK DIAGRAM

Propel

Control

Valve

XVIII. Propel Circuit

Form No. 29703

60

Propel

Motor

Interface

Valve

Center

Pin

Tank

Main

Pump

Propel

Pedal

Pilot Pressure

Tank

Rev.

Fwd.

Rev.

P - Pilot Pressure

T - Return Fluid to Tank

A - Control Valve Port - Reverse

B - Control Valve Pon - forward

Check Valve

Orfice Check Valve

E - Center Pin Port - Case Drain

F - Center Pin Pon - Interface Value

1 & 2 - Center Pin Port To Propel Motor

Double Check Valve

Fwd.

Fwd.

Rev.

l

l

l

l

l

l

NOTE!

Hydraulic Fluid Path Simplified for Clarity

Содержание XL4000

Страница 2: ......

Страница 73: ......

Страница 76: ... 5MP ...

Страница 145: ......

Страница 146: ......

Страница 151: ...From No 296020 2 97 4 FIGURE 4 FIGURE 5 FIGURE 3 IV Saving Charge and Pilot Pressure continued ...

Страница 160: ......

Страница 161: ......

Страница 162: ......

Страница 175: ......

Страница 176: ......

Страница 177: ......

Страница 178: ......

Страница 192: ......

Страница 193: ......

Страница 194: ......

Страница 207: ......

Страница 208: ......

Страница 210: ...500P ...

Страница 229: ......

Страница 230: ......

Страница 245: ......

Страница 246: ......

Страница 247: ......

Страница 248: ......

Страница 265: ......

Страница 266: ......

Страница 267: ......

Страница 268: ......

Страница 280: ......

Страница 281: ......

Страница 282: ......

Страница 297: ......

Страница 298: ......

Страница 299: ......

Страница 300: ......

Страница 301: ......

Страница 302: ......

Страница 303: ......

Страница 304: ......

Страница 305: ...GRADALL h y d r a u l i c e x c a v a t o r s XL 4000 5000 CENTER PIN REBUILD Form No 20026 Part No 2460 4164 ...