V. Pump Horsepower Adjustment

The following procedure is for testing and setting the pump horsepower adjustment. The pump horsepower

affects the point the pump de-strokes to keep from drawing more horsepower than con be delivered. This test

con be affected by the weight of material in the bucket. It is recommended that the biggest bucket available for

the machine, heaped with dirt, be used to set pump horsepower. If the pump horsepower adjustment is altered,

a new seal cop must be installed on the pump horsepower adjustment screw.

All pressures must be correct before testing pump horsepower. If any pressures ore incorrect, the

pump horsepower setting will be affected.

Use the tachometer on the monitor system for this procedure. The largest bucket available must be heaped with

dirt. Then with the machine in a clear area, place the bucket on the ground. On XL 4100 and XL 5100 machines,

make sure that the boom will not come in contact with the carrier cab while swinging. When testing the pump

horsepower of these models, it is recommended that the bucket be placed on the ground, on the left-hand side

of the machine. The machine should be swung to the left. Do not stall any function while performing this test.

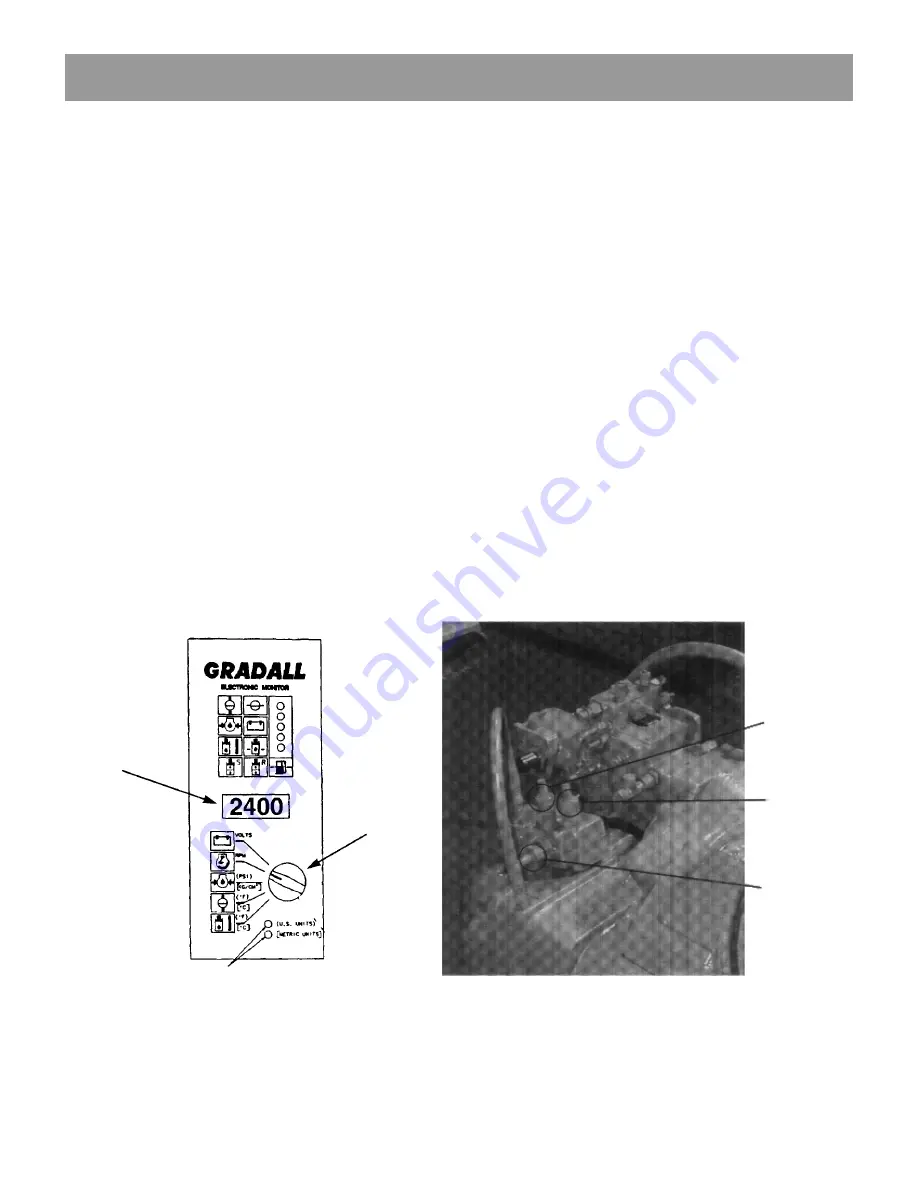

See Figure 5.

With the full bucket on the ground and the engine at full RPM, use the controls to hoist-up, boom-out and

swing left at the some time. Observe engine RPM. It should not drop below 1,900 RPM. If adjustment is

required, use the horsepower adjustment screw (front adjustment screw on front of pump controls on main

pump). Turning the screw clockwise decreases RPM drawdown; turning the screw counter-clockwise increases RPM

drawdown.

See Figure 6.

FIGURE 5

ELECTRONIC MONITOR PANEL

NOTE!

1.

2.

FIGURE 6

PUMP CONTROLS

Pump Cut-off

Adjustment Screw

Pump Horsepower

Adjustment Screw

Pump Standby

Adjustment Screw

Use display to

check RPM drop

GREEN LEDS

Set switch

to RPM

Form No. 29705 3/99

10

Содержание XL4000

Страница 2: ......

Страница 73: ......

Страница 76: ... 5MP ...

Страница 145: ......

Страница 146: ......

Страница 151: ...From No 296020 2 97 4 FIGURE 4 FIGURE 5 FIGURE 3 IV Saving Charge and Pilot Pressure continued ...

Страница 160: ......

Страница 161: ......

Страница 162: ......

Страница 175: ......

Страница 176: ......

Страница 177: ......

Страница 178: ......

Страница 192: ......

Страница 193: ......

Страница 194: ......

Страница 207: ......

Страница 208: ......

Страница 210: ...500P ...

Страница 229: ......

Страница 230: ......

Страница 245: ......

Страница 246: ......

Страница 247: ......

Страница 248: ......

Страница 265: ......

Страница 266: ......

Страница 267: ......

Страница 268: ......

Страница 280: ......

Страница 281: ......

Страница 282: ......

Страница 297: ......

Страница 298: ......

Страница 299: ......

Страница 300: ......

Страница 301: ......

Страница 302: ......

Страница 303: ......

Страница 304: ......

Страница 305: ...GRADALL h y d r a u l i c e x c a v a t o r s XL 4000 5000 CENTER PIN REBUILD Form No 20026 Part No 2460 4164 ...