II.

II.

II.

II.

II. R

R

R

R

Reser

eser

eser

eser

eservvvvvoir

oir

oir

oir

oir Air Pr

Air Pr

Air Pr

Air Pr

Air Pressur

essur

essur

essur

essure

ee

e

e

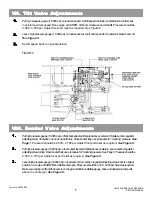

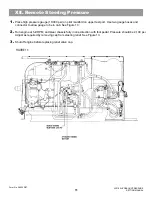

Build air pressure up in the upperstructure for remote operation. Shut engine off.

At reservoir breather located next to the engine, push release plunger to expel all air pressure in the hydraulic

tank.

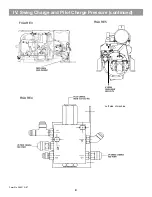

See Figure 1

Observe reservoir pressure gauge as pressure builds up. Reservoir pressure should be at least 6 but preferably

8 psi. If pressure is too high or low, adjust regulator, dump tank pressure and recheck (regulator and gauge are

attached to filter bracket on engine above air compressor).

See Figure 1.

FIGURE 1

Form No. 29622 2/97

2

1.

1.

1.

1.

1.

2.

2.

2.

2.

2.

3.

3.

3.

3.

3.

Содержание XL4000

Страница 2: ......

Страница 73: ......

Страница 76: ... 5MP ...

Страница 145: ......

Страница 146: ......

Страница 151: ...From No 296020 2 97 4 FIGURE 4 FIGURE 5 FIGURE 3 IV Saving Charge and Pilot Pressure continued ...

Страница 160: ......

Страница 161: ......

Страница 162: ......

Страница 175: ......

Страница 176: ......

Страница 177: ......

Страница 178: ......

Страница 192: ......

Страница 193: ......

Страница 194: ......

Страница 207: ......

Страница 208: ......

Страница 210: ...500P ...

Страница 229: ......

Страница 230: ......

Страница 245: ......

Страница 246: ......

Страница 247: ......

Страница 248: ......

Страница 265: ......

Страница 266: ......

Страница 267: ......

Страница 268: ......

Страница 280: ......

Страница 281: ......

Страница 282: ......

Страница 297: ......

Страница 298: ......

Страница 299: ......

Страница 300: ......

Страница 301: ......

Страница 302: ......

Страница 303: ......

Страница 304: ......

Страница 305: ...GRADALL h y d r a u l i c e x c a v a t o r s XL 4000 5000 CENTER PIN REBUILD Form No 20026 Part No 2460 4164 ...