Form No. 29621 2/97

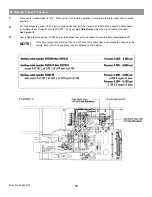

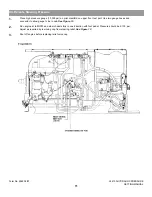

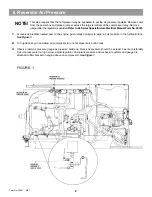

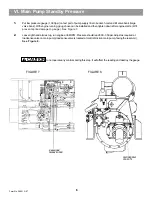

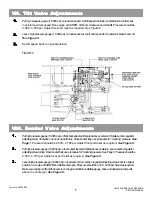

Move high pressure gauge (10,000 psi) to front hoist test port. Run engine at full RPM, lower boom to ground

and stall hoist. Pressure should be 2,200 - 2,400 psi. Adjust front port relief as required.

See Figure 10.

Move high pressure gauge (10,000 psi) to rear test port. Rotate section regulator adjusting screw clockwise one

and one-half turns. Raise hoist fully up, use procedure for “cracking pressure.

See Page 1. Pressure should be

4,100 - 4,150 psi. Adjust rear port relief as needed.

See Figure 10.

Leave high pressure gauge (10,000 psi) on rear hoist test port. Return section regulator adjusting screw to original

position. Run engine at full RPM and stall hoist up. Pressure should be 3,900 - 3,950 psi. Adjust section regulator as

required.

See Figure 10.

NOTE!

NOTE!

NOTE!

NOTE!

NOTE!

Perform the following test only if doing an inspection, or if hoist performance is in question.

Use stopwatch for this step. Remove high pressure gauge (10,000 psi) from hoist valve. Retract boom fully and

place on ground with an empty bucket. Run engine at full RPM and raise boom from ground to fully up. It should

take 3.3 - 3.6 seconds to fully raise boom. If hoist-up speed needs adjusted, remove plug from stroke limiter on

front end cap. Adjust as required.

See Figure 10.

FIGURE 10

8

1.

2.

3.

4.

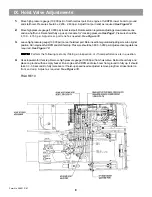

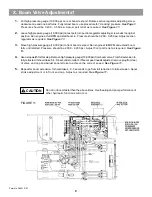

IX. Hoist Valve Adjustments

Содержание XL4000

Страница 2: ......

Страница 73: ......

Страница 76: ... 5MP ...

Страница 145: ......

Страница 146: ......

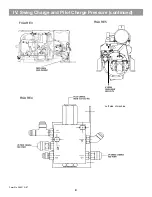

Страница 151: ...From No 296020 2 97 4 FIGURE 4 FIGURE 5 FIGURE 3 IV Saving Charge and Pilot Pressure continued ...

Страница 160: ......

Страница 161: ......

Страница 162: ......

Страница 175: ......

Страница 176: ......

Страница 177: ......

Страница 178: ......

Страница 192: ......

Страница 193: ......

Страница 194: ......

Страница 207: ......

Страница 208: ......

Страница 210: ...500P ...

Страница 229: ......

Страница 230: ......

Страница 245: ......

Страница 246: ......

Страница 247: ......

Страница 248: ......

Страница 265: ......

Страница 266: ......

Страница 267: ......

Страница 268: ......

Страница 280: ......

Страница 281: ......

Страница 282: ......

Страница 297: ......

Страница 298: ......

Страница 299: ......

Страница 300: ......

Страница 301: ......

Страница 302: ......

Страница 303: ......

Страница 304: ......

Страница 305: ...GRADALL h y d r a u l i c e x c a v a t o r s XL 4000 5000 CENTER PIN REBUILD Form No 20026 Part No 2460 4164 ...