III. Hoses, Tubing and Clamping

Hoses, tubing and the clamping method of each is designed to provide maximum operating life and safety

values of these components. Hoses and tubing should always be protected from vibrating against each other or

sharp edges which could wear a hole in them causing failure and a safety concern.

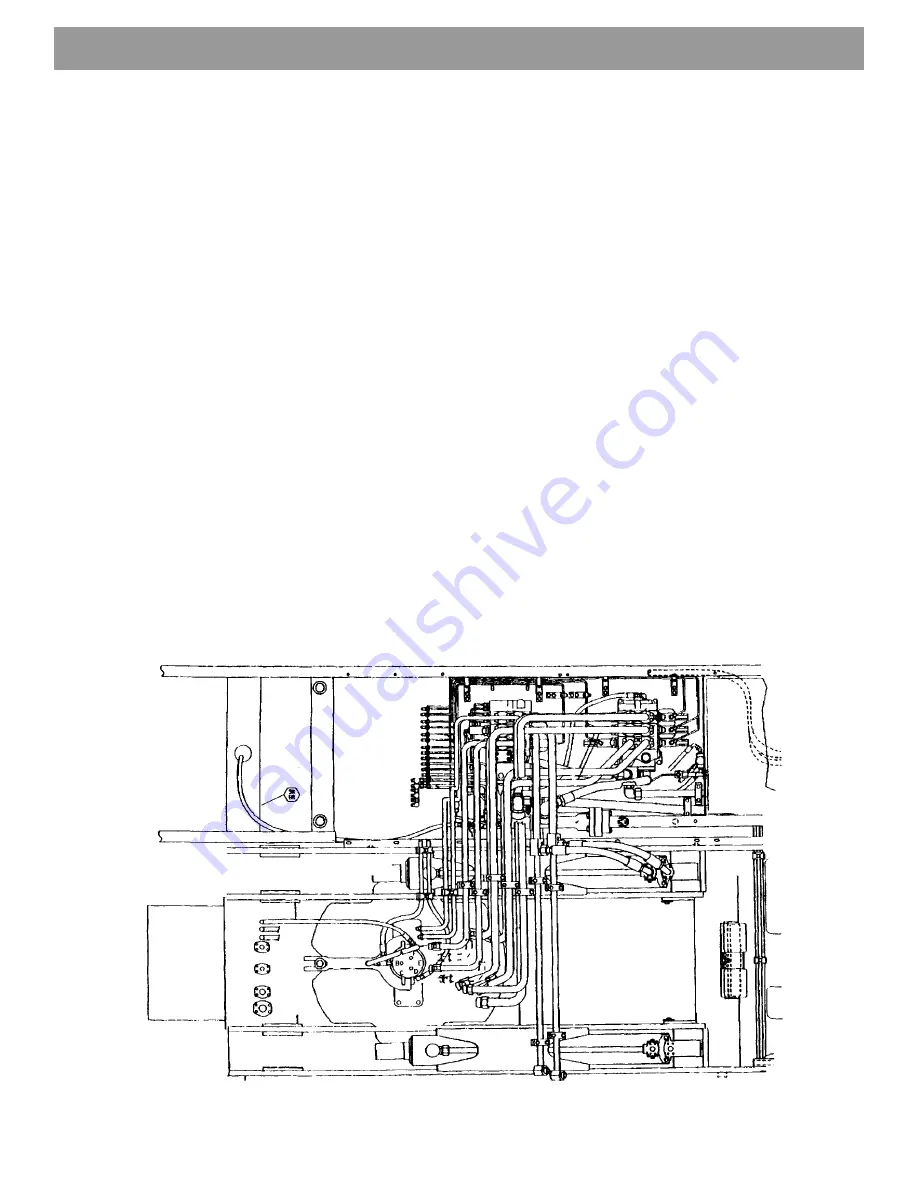

See Figure 1

Hoses:

A hose should never be used in a circuit without a minimum safety margin burst pressure of at least 4 to

1to the highest acheivable circuit pressure. Replacement hoses should be stored in a dry atmosphere with a

storage life not to exceed 3 years.

Tubing:

Hydraulic tubing should not be used in a circuit without a minimum safety margin burst pressure of at

least 4 to 1 to the highest achievable circuit pressure. Tubing used on the GRADALL is equipped with a circuit test

port. The use of tubing also assists with system heat disapation. Replacement tubing should be stored in a dry

atmosphere and must be free of rust and contaminants.

Clamping:

Hose and tubing runs are protected from unwanted movement by clamping. Clamps should be sized

correctly for the hose or tube on which it is used. Multiple hose/tubing clamps are available and their use is

recommended where possible. Do not operate the machine with damaged or broken clamps. The appropriate

Gradall Parts Manual for the machine lists all hose/tubing clamps used and their location is shown on the

parts page.

Replacement hose and tubing should be supplied by your GRADALL distributor. The use of Generic replacement

hose and tubing is not recommended.

Hose fitting torque values are listed in Appendix A. Adherence to these values will greatly eliminate the possibility

of fittings working loose causing fluid leakage.

FIGURE 1

HOSE & TUBING CONTROL VALVE AREA

4

Form No. 29703

Содержание XL4000

Страница 2: ......

Страница 73: ......

Страница 76: ... 5MP ...

Страница 145: ......

Страница 146: ......

Страница 151: ...From No 296020 2 97 4 FIGURE 4 FIGURE 5 FIGURE 3 IV Saving Charge and Pilot Pressure continued ...

Страница 160: ......

Страница 161: ......

Страница 162: ......

Страница 175: ......

Страница 176: ......

Страница 177: ......

Страница 178: ......

Страница 192: ......

Страница 193: ......

Страница 194: ......

Страница 207: ......

Страница 208: ......

Страница 210: ...500P ...

Страница 229: ......

Страница 230: ......

Страница 245: ......

Страница 246: ......

Страница 247: ......

Страница 248: ......

Страница 265: ......

Страница 266: ......

Страница 267: ......

Страница 268: ......

Страница 280: ......

Страница 281: ......

Страница 282: ......

Страница 297: ......

Страница 298: ......

Страница 299: ......

Страница 300: ......

Страница 301: ......

Страница 302: ......

Страница 303: ......

Страница 304: ......

Страница 305: ...GRADALL h y d r a u l i c e x c a v a t o r s XL 4000 5000 CENTER PIN REBUILD Form No 20026 Part No 2460 4164 ...