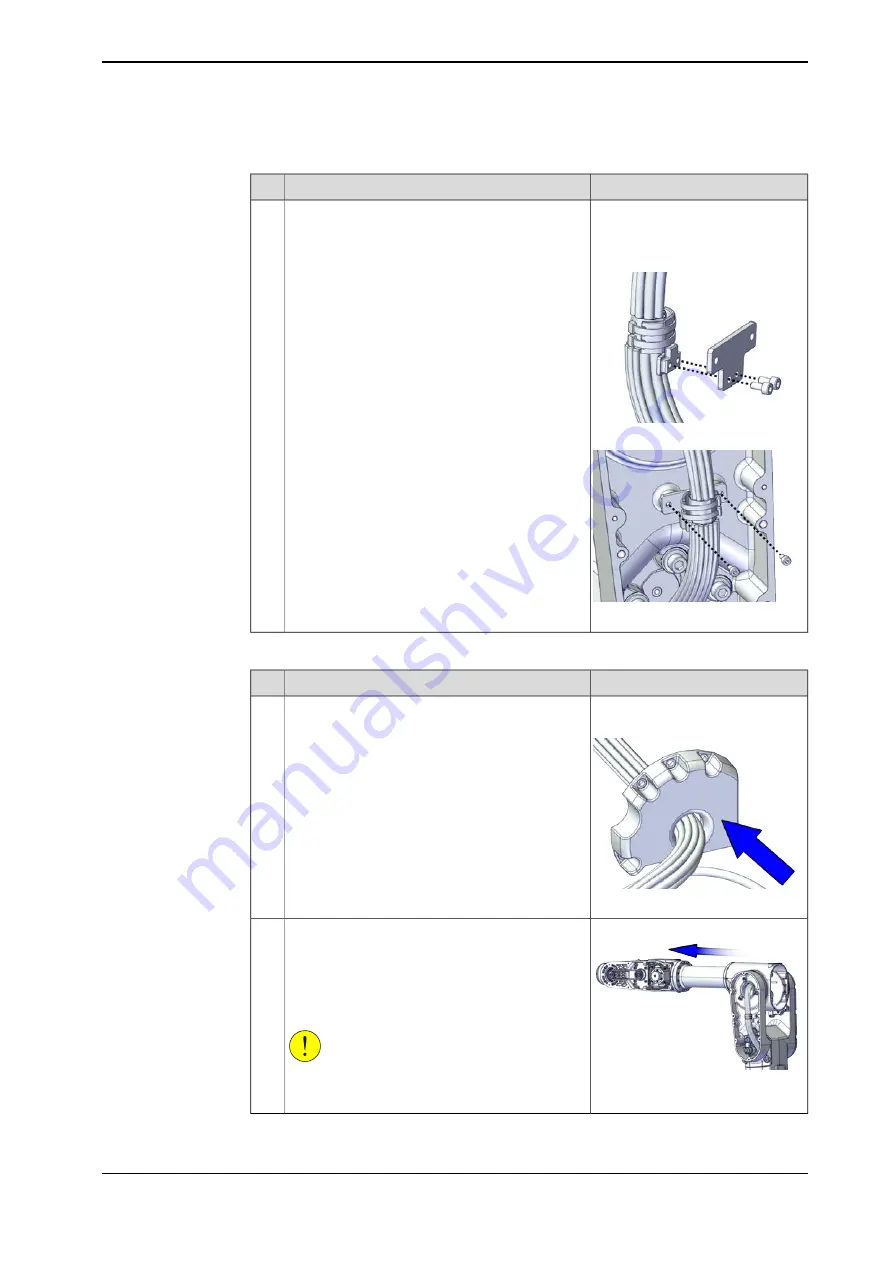

Securing the cable package in the lower arm

Note

Action

Screw: M4x8 12.9 Lafre

2C2B/FC6.9 (2 pcs on the cable

package and 2 pcs on lower arm)

Refit the cable bracket.

1

Tightening torque: 2.6 Nm

xx2100001465

xx2000001553

Routing the cable package in the housing

Note

Action

Plastic cable protector, axis 4:

Slip the axis-4 cable protector over the cable

package.

1

3HAC064694-001:

xx2000001570

xx2000001571

Insert the cable package through the hollow tube

of the axis-4 gearbox, into the extender unit (only

for CRB 1300-7/1.4 and ) and into the tubular.

Make sure that:

•

the air hoses are facing the axis-3 gearbox

side in the hollow tube of axis-4 gearbox.

CAUTION

Make sure that no cables or hoses are twisted or

strained. Reroute if necessary.

2

Continues on next page

Product manual - CRB 1300

591

3HAC083111-001 Revision: B

© Copyright 2022-2023 ABB. All rights reserved.

5 Repair

5.7.2 Replacing the axis-2 gearbox

Continued

Содержание CRB 1300

Страница 1: ...ROBOTICS Product manual CRB 1300 ...

Страница 2: ...Trace back information Workspace 23A version a14 Checked in 2023 03 20 Skribenta version 5 5 019 ...

Страница 50: ...This page is intentionally left blank ...

Страница 662: ...This page is intentionally left blank ...

Страница 690: ...This page is intentionally left blank ...

Страница 704: ...This page is intentionally left blank ...

Страница 720: ...This page is intentionally left blank ...

Страница 725: ......