System Setup

9

-

85

9.2

Setting the second home position (check point)

9.2.1

Purpose of position check operation

If the absolute number of rotation detected at power supply ON does not match the data

stored in the absolute encoder the last time the power supply was turned off, alarm 4107

“OUT OF RANGE (ABSO DATA)” is issued when the controller power is turned ON.

There are two possible causes of this alarm:

•

An error was found in the encoder communication related components.

•

No error was found in the encoder communication related components, but the robot

was moved after the power supply was turned OFF.

If there is an error in the encoder communication related components, the robot may stall

when playback is started. If the absolute data allowable range error alarm has occurred,

playback and test runs will not function and the position must be checked.

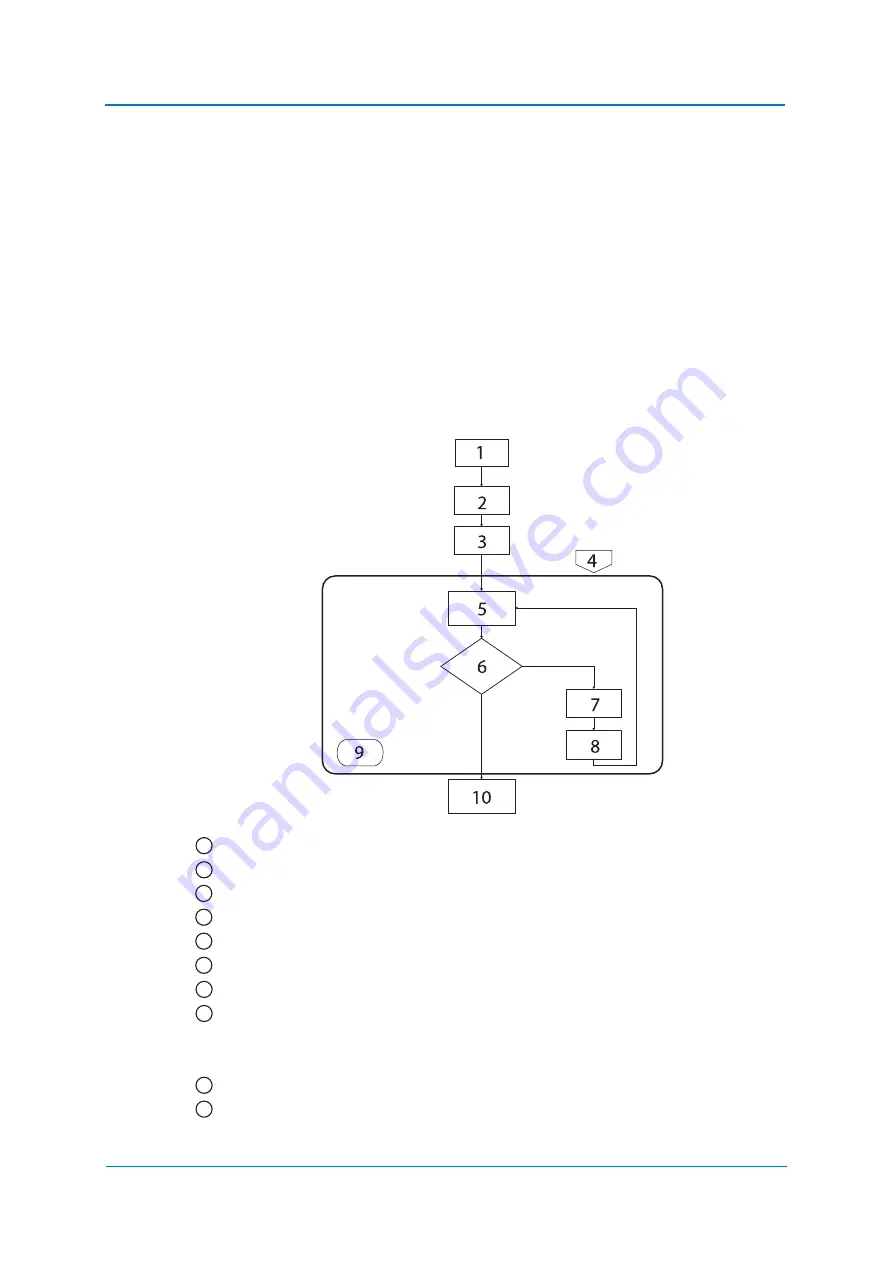

If the "OUT OF RANGE (ABSO DATA)" alarm occurs:

Reset alarm

Turn ON SERVO power

Procedure after alarm occurs

Position confirmation operation

Compare second home position (check point)* with current position pulses.

Alarm occurs again

Correct defective axis

• Replace encoder communication related components

• Home position calibration

* Position checking point

Playback possible

OK

NOK

1

2

3

4

5

6

7

8

9

10

Summary of Contents for YRC1000

Page 1: ...ROBOTICS Instructions Robot controller User manual ...

Page 30: ...Supply 3 30 Hood for CEE connector Covers ...

Page 51: ...Connection 5 51 8 Close the YRC1000 door ...

Page 142: ...System Setup 9 142 6 Select YES All data of the interference signal number is deleted ...

Page 174: ...System Setup 9 174 7 Press ENTER The speed is modified ...

Page 219: ...System Setup 9 219 4 Select GRAPH The graph appears 4 5 6 7 8 9 10 1 2 3 ...

Page 453: ...Description of Units and Circuit Boards 15 453 ...