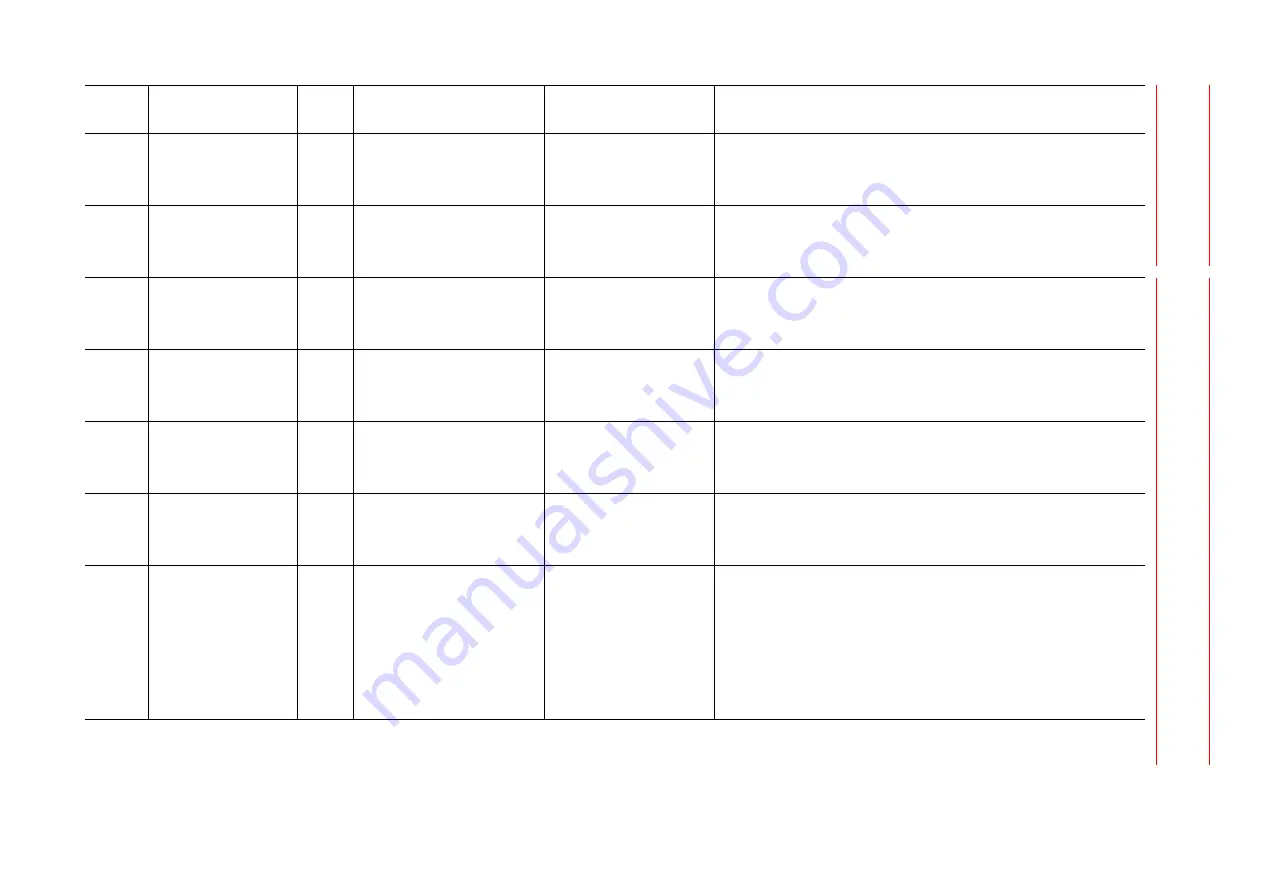

Alar

m List

Alar

m Nu

mbe

r (4

00

0 to

4

9

99

)

Alarm List-573

14

Path control position data

error of pre-reading bank

Software operation error

occurred

(1)Reset the alarm, and then try again.

(2)If the alarm occurs again, save the CMOS.BIN in maintenance

mode, and then contact your Yaskawa representative about

occurrence status (operating procedure).

16

Station/base axis motion

command error

Software operation error

occurred

(1)Reset the alarm, and then try again.

(2)If the alarm occurs again, save the CMOS.BIN in maintenance

mode, and then contact your Yaskawa representative about

occurrence status (operating procedure).

18

User coordinates number

error

Software operation error

occurred

(1)Reset the alarm, and then try again.

(2)If the alarm occurs again, save the CMOS.BIN in maintenance

mode, and then contact your Yaskawa representative about

occurrence status (operating procedure).

19

Processing error in re-

preparation of segment

control data

Software operation error

occurred

(1)Reset the alarm, and then try again.

(2)If the alarm occurs again, save the CMOS.BIN in maintenance

mode, and then contact your Yaskawa representative about

occurrence status (operating procedure).

20

Pre-reading task not

completed at master in twin

synchronous system

Software operation error

occurred

(1)Reset the alarm, and then try again.

(2)If the alarm occurs again, save the CMOS.BIN in maintenance

mode, and then contact your Yaskawa representative about

occurrence status (operating procedure).

23

Dynamic model arithmetic

error

Software operation error

occurred

(1)Reset the alarm, and then try again.

(2)If the alarm occurs again, save the CMOS.BIN in maintenance

mode, and then contact your Yaskawa representative about

occurrence status (operating procedure).

24

Speed limit control error

(excessive moment of gravity)

Setting error

(1)Check the following settings.

∙

The allowable breaking torque was exceeded only by the gravity

moment. Set the gravity value of the tool within payload of the

manipulator.

∙

Teach the manipulator orientation that does not become the overload

for each-axes of the manipulator.

(2)If the alarm occurs again, save the CMOS.BIN in maintenance

mode, and then contact your Yaskawa representative about

occurrence status (operating procedure).

Alarm

Number

Alarm Name

Sub

Code

Meaning

Cause

Remedy