Summary of Contents for MBK XMAX 2014

Page 1: ...2014 SERVICE MANUAL YP125R YP125RA 2DM F8197 E0 ...

Page 6: ......

Page 8: ......

Page 64: ...TIGHTENING TORQUES 2 17 Muffler tightening sequence 1 2 3 ...

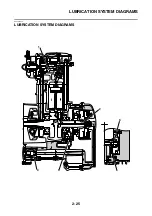

Page 72: ...LUBRICATION SYSTEM DIAGRAMS 2 25 EAS2DM1116 LUBRICATION SYSTEM DIAGRAMS 1 2 3 4 5 3 ...

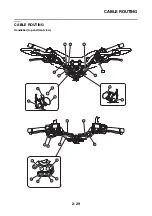

Page 78: ...CABLE ROUTING 2 31 Steering head front view 1 2 3 4 5 6 8 8 A 7 7 ...

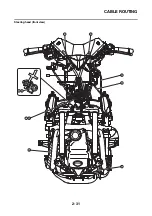

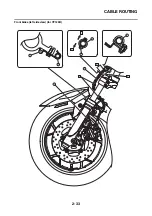

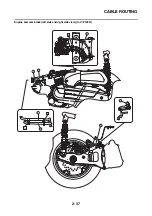

Page 80: ...CABLE ROUTING 2 33 Front brake left side view for YP125R 1 2 2 1 1 2 2 D E A B C ...

Page 82: ...CABLE ROUTING 2 35 Front brake left side view for YP125RA 2 1 1 2 1 2 2 A B D E C ...

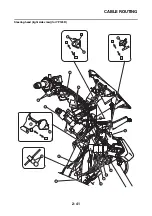

Page 92: ...CABLE ROUTING 2 45 Frame right side view 3 2 4 1 2 3 A B 6 5 3 A B 3 3 2 3 3 A A B A B B 3 ...

Page 94: ...CABLE ROUTING 2 47 Engine right side view 6 6 6 6 C D C D D C 10 B 9 5 6 1 2 8 3 4 5 6 7 A ...

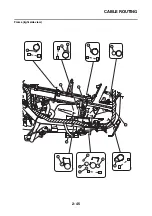

Page 98: ...CABLE ROUTING 2 51 Frame left side view C D C D 2 1 E 1 2 D C 6 1 4 5 3 2 1 7 3 2 1 A B ...

Page 100: ...CABLE ROUTING 2 53 Engine left side view 1 1 1 1 1 2 3 4 5 6 7 8 9 7 7 A B A B A B 1 ...

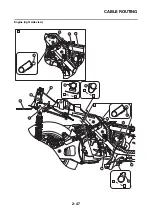

Page 106: ...CABLE ROUTING 2 59 Rear brake right side view 2 2 2 2 2 2 1 1 2 3 A B C 3 ...

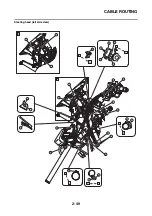

Page 110: ...CABLE ROUTING 2 63 ...

Page 228: ...REAR SHOCK ABSORBER ASSEMBLIES AND SWINGARM 4 89 ...

Page 231: ......

Page 291: ...CRANKSHAFT 5 60 a 1 ...

Page 292: ...CRANKSHAFT 5 61 ...

Page 302: ...WATER PUMP 6 9 ...

Page 313: ......

Page 331: ...CHARGING SYSTEM 8 18 ...

Page 349: ...COOLING SYSTEM 8 36 ...

Page 391: ...FUEL PUMP SYSTEM 8 78 ...

Page 400: ...IMMOBILIZER SYSTEM 8 87 a Light on b Light off ...

Page 401: ...IMMOBILIZER SYSTEM 8 88 ...

Page 405: ...ABS ANTI LOCK BRAKE SYSTEM for YP125RA 8 92 ...

Page 439: ...ABS ANTI LOCK BRAKE SYSTEM for YP125RA 8 126 ...

Page 464: ...ELECTRICAL COMPONENTS 8 151 ...

Page 476: ......

Page 477: ......

Page 478: ......