7-68

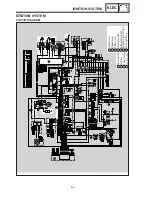

SWINGARM AND DRIVE CHAIN

CHAS

70 Nm (7.0 m

kg)

NOTE:

CAUTION:

CAUTION:

4. Adjust:

drive chain slack

Refer to “ADJUSTING THE DRIVE CHAIN

SLACK” in chapter 3.

Drive chain slack

30

45 mm

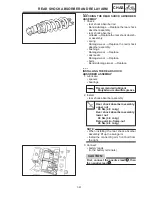

EB707710

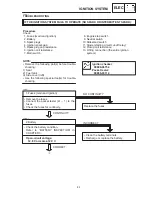

INSTALLING THE DRIVE CHAIN

1. Lubricate:

drive chain

Recommended lubricant

Engine oil or chain lubricant

suitable for O-ring chains

2. Install:

drive chain

1

drive sprocket

2

washer

3

drive sprocket nut

4

While applying the rear brake, tighten the

drive sprocket nut.

Never install a new drive chain onto worn

drive chain sprockets; this will dramati-

cally shorten the drive chain’s life.

5. Adjust:

drive chain slack

Refer to “ADJUSTING THE DRIVE CHAIN

SLACK” in chapter 3.

Drive chain slack

30

45 mm

A drive chain that is too tight will over-

load the engine and other vital parts, and

one that is too loose can skip and dam-

age the swingarm or cause an accident.

Therefore, keep the drive chain slack

within the specified limits.

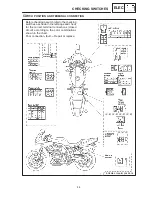

Summary of Contents for 1998 FZS600 5DM1-AE1

Page 1: ......

Page 2: ......

Page 8: ......

Page 9: ...GEN INFO 1 ...

Page 11: ...GEN INFO ...

Page 20: ...SPEC 2 ...

Page 22: ...SPEC ...

Page 46: ...2 24 1 2 LUBRICATION DIAGRAMS SPEC 1 Camshaft 2 Crankshaft ...

Page 54: ...SPEC ...

Page 55: ...CHK ADJ 3 ...

Page 57: ...CHK ADJ ...

Page 109: ...CHK ADJ ...

Page 110: ...ENG 4 ...

Page 189: ...COOL 5 ...

Page 191: ...COOL ...

Page 202: ...CARB 6 ...

Page 204: ...CARB ...

Page 216: ...6 12 CARB ...

Page 217: ...CHAS 7 ...

Page 288: ...ELEC 8 ...

Page 290: ...ELEC ...

Page 292: ...8 2 CIRCUIT DIAGRAM ELEC CIRCUIT DIAGRAM ...

Page 326: ...8 36 SIGNAL SYSTEM ELEC EB806000 SIGNAL SYSTEM CIRCUIT DIAGRAM ...

Page 355: ...TRBL SHTG 9 ...

Page 357: ...TRBL SHTG ...

Page 363: ...TRBL SHTG ...