SPEC

CHAPTER 2

SPECIFICATIONS

GENERAL SPECIFICATIONS

2-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE SPECIFICATIONS

2-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE

2-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHASSIS

2-10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL

2-14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL TIGHTENING TORQUE SPECIFICATIONS

2-17

. . . . . . . . . . . . . . . . . . . . . . .

LUBRICATIONS AND LUBRICANT TYPES

2-18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE

2-18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHASSIS

2-19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COOLING SYSTEM DIAGRAMS

2-20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LUBRICATION DIAGRAMS

2-22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CABLE ROUTING

2-25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Summary of Contents for 1998 FZS600 5DM1-AE1

Page 1: ......

Page 2: ......

Page 8: ......

Page 9: ...GEN INFO 1 ...

Page 11: ...GEN INFO ...

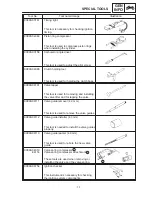

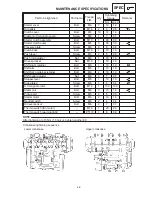

Page 20: ...SPEC 2 ...

Page 22: ...SPEC ...

Page 46: ...2 24 1 2 LUBRICATION DIAGRAMS SPEC 1 Camshaft 2 Crankshaft ...

Page 54: ...SPEC ...

Page 55: ...CHK ADJ 3 ...

Page 57: ...CHK ADJ ...

Page 109: ...CHK ADJ ...

Page 110: ...ENG 4 ...

Page 189: ...COOL 5 ...

Page 191: ...COOL ...

Page 202: ...CARB 6 ...

Page 204: ...CARB ...

Page 216: ...6 12 CARB ...

Page 217: ...CHAS 7 ...

Page 288: ...ELEC 8 ...

Page 290: ...ELEC ...

Page 292: ...8 2 CIRCUIT DIAGRAM ELEC CIRCUIT DIAGRAM ...

Page 326: ...8 36 SIGNAL SYSTEM ELEC EB806000 SIGNAL SYSTEM CIRCUIT DIAGRAM ...

Page 355: ...TRBL SHTG 9 ...

Page 357: ...TRBL SHTG ...

Page 363: ...TRBL SHTG ...