4-18

VALVES AND VALVE SPRINGS

ENG

1

a

NOTE:

NOTE:

NOTE:

NOTE:

EB403100

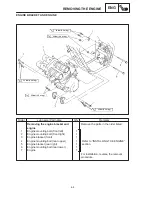

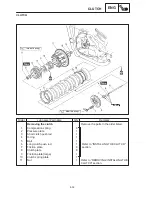

REMOVING THE VALVES

The following procedure applies to all of the

valves and related components.

Before removing the internal parts of the

cylinder head (e.g., valves, valve springs,

valve seats), make sure that the valves

properly seal.

1. Remove:

valve lifter

1

valve pad

Make a note of the position of each valve

lifter and valve pad so that they can be

reinstalled in their original place.

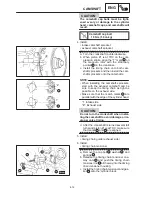

2. Check:

valve sealing

Leakage at the valve seat

Check the

valve face, valve seat, and valve seat

aidth.

Refer to “CHECKING THE VALVE

SEATS”.

a. Pour a clean solvent

a

into the intake

and exhaust ports.

b. Check that the valves properly seal.

There should be no leakage at the valve

seat

1

.

3. Remove:

valve cotters

1

Remove the valve cotters by compressing

the valve spring with the valve spring com-

pressor

2

and attachment

3

.

Valve spring compressor

90890-04019

Attachment

90890-04114

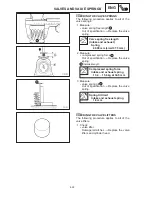

4. Remove:

upper spring seat

1

valve spring

2

oil seal

3

lower spring seat

4

valve

5

Identify the position of each part very care-

fully so that it can be reinstalled in its original

place.

Summary of Contents for 1998 FZS600 5DM1-AE1

Page 1: ......

Page 2: ......

Page 8: ......

Page 9: ...GEN INFO 1 ...

Page 11: ...GEN INFO ...

Page 20: ...SPEC 2 ...

Page 22: ...SPEC ...

Page 46: ...2 24 1 2 LUBRICATION DIAGRAMS SPEC 1 Camshaft 2 Crankshaft ...

Page 54: ...SPEC ...

Page 55: ...CHK ADJ 3 ...

Page 57: ...CHK ADJ ...

Page 109: ...CHK ADJ ...

Page 110: ...ENG 4 ...

Page 189: ...COOL 5 ...

Page 191: ...COOL ...

Page 202: ...CARB 6 ...

Page 204: ...CARB ...

Page 216: ...6 12 CARB ...

Page 217: ...CHAS 7 ...

Page 288: ...ELEC 8 ...

Page 290: ...ELEC ...

Page 292: ...8 2 CIRCUIT DIAGRAM ELEC CIRCUIT DIAGRAM ...

Page 326: ...8 36 SIGNAL SYSTEM ELEC EB806000 SIGNAL SYSTEM CIRCUIT DIAGRAM ...

Page 355: ...TRBL SHTG 9 ...

Page 357: ...TRBL SHTG ...

Page 363: ...TRBL SHTG ...