April 2017

4-238

Xerox® VersaLink® B7025/B7030/B7035 Multifunction Printer

ADJ 60.5, ADJ 60.6

Launch Issue

Repairs and Adjustments

ADJ 60.5 Optics Cleaning Procedure

Parts List on

PL 60.10

Purpose

To clean the optics components of the scanner ensuring optimum image quality.

NOTE: This adjustment must only be performed if directed to from an Image Quality RAP, or if

the optics cavity was opened to install a new component and contamination can be seen on

the optics components.

Procedure

WARNING

Ensure that the electricity to the machine is switched off while performing tasks that do

not need electricity. Refer to

GP 10

. Disconnect the power cord. Electricity can cause

death or injury. Moving parts can cause injury.

1.

Remove the document glass,

REP 60.1

.

2.

Inspect the cleanliness of the optics mirrors, if necessary, clean them as follows:

a.

Vacuum clean the area to remove all visible contamination, taking care not to touch

the mirrors with the cleaning nozzle. It may be necessary to move the carriages to

gain reasonable access, do this by hand rotation of the flywheel on the capstan

shaft.

b.

Wash your hands.

c.

Carefully clean the mirrors using a dry micro fiber wiper. It may be necessary to use

a cleaning cloth dampened with film remover on stubborn contamination.

d.

Polish the mirrors with a dry micro fiber wiper.

e.

Check that the mirror surfaces are now clean. Repeat the cleaning operation if nec-

essary.

f.

Examine the lenses of the APS sensors,

PL 60.10 Item 10

. Clean if necessary with a

micro fiber wiper.

3.

Inspect the cleanliness of the document glass and CVT glass, if necessary, clean them as

follows:

a.

Clean the under side of document glass and CVT glass using a micro fiber wiper,

dampened with film remover.

b.

Polish the under side of document glass and CVT glass with a dry micro fiber wiper.

c.

Install the document glass and CVT glass, taking care not to smear the cleaned

underside.

d.

Clean the upper side of document glass and CVT glass using a micro fiber wiper,

dampened with film remover.

e.

Polish the upper side of document glass and CVT glass using a dry micro fiber

wiper.

4.

Re-install the remainder of the removed components.

ADJ 60.6 CDD Lens Optical Axis Correction

Parts List on

PL 60.10

Purpose

To correctly set the CCD lens optical axis after installation of a new CCD lens.

Check

1.

Enter

dC945

IIT Calibration.

2.

Perform the Optical Axis Correction procedure.

3.

On the result screen, if OK is displayed, no further action is necessary. If NG is displayed,

perform the Adjustment. Refer to

Table 1

.

Adjustment

1.

The result screen will show the information depicted in

Table 1

:

•

Front nut refers to the nut at the front of the CCD lens assembly, refer to

Figure 1

.

•

Rear nut refers to the nut at the rear of the CCD lens assembly, refer to

Figure 1

.

•

+ Refers to clockwise rotation.

•

- Refers to counter-clockwise rotation.

•

Numeral: refers to the adjustment angle (degrees).

Using the content of

Table 1

as an example:

•

The front nut must be rotated 90 degrees clockwise.

•

The rear nut must be rotated 260 degrees counter clockwise.

NOTE: If the value is abnormally high, for example 990, it may be due to the light path

being blocked. Perform

ADJ 60.5

Optics Cleaning Procedure, then repeat the Check.

2.

Rotate each nut the required amount.

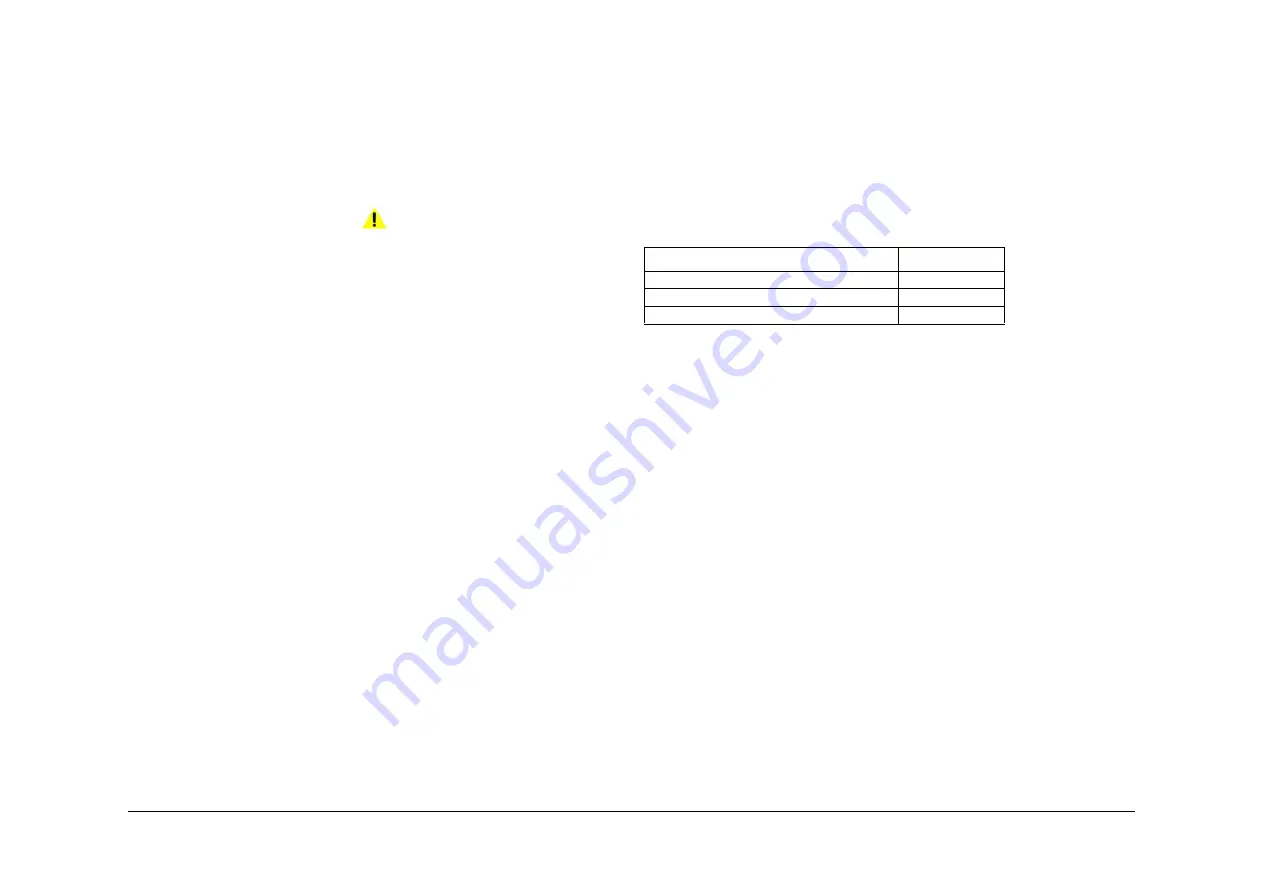

Table 1 Result

Optical Axis Correction

Optical Axis Correction Result

NG

Front Nut Correction Angle -: Left rotation

+90

Rear Nut Correction Angle +: Right rotation

-260