STRATA DK FAULT FINDING

SECTION 400-096-500

SEPTEMBER 1992

-2-

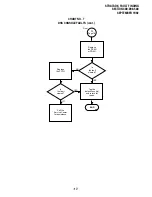

3.05 The flowcharts are sequentially arranged to

permit rapid fault localization within the system. All

fault clearing must begin with the Fault Classifica-

tion Flowchart, which is arranged in the correct

fault locating sequence.

3.06 The following precautions must be observed

when handling PCBs:

DO NOT:

•

Drop a PCB.

•

Stack one PCB on top of another.

•

Handle a PCB without discharging any static

electricity from your person by touching the

grounded cabinet.

•

Touch PCB contacts with your fingers.

Important!

If the fault is not cleared by substituting a

PCB, the original PCB must be reinstalled

in the cabinet before trying another PCB.

4

DEFECTIVE APPARATUS RETURNS

4.01 When a defective system apparatus is shipped

for repair, the apparatus must be packed in a

suitable container (the original box is highly

recommended), as follows:

a) Paper container for the PCTU PCB.

b) Anti-static containers for all other PCBs

c) Plastic bags for digital or electronic tele-

phones, KSU, etc.

4.02 NEVER WRITE ON THE APPARATUS

ITSELF! Describe the nature of the defect on an

information tag. Attach the tag to the front of the

unit with string (not wire) so the tag can remain

attached during the testing and repair process.

Return tags are available from Toshiba America

Information Systems, Inc., TSD Division.

5

FAULT IDENTIFICATION AND

ELIMINATION PROCEDURES

5.01 The PCTU PCB may contain a ÒsoftÓ fault due

to static electricity. If it is found defective during the

fault finding procedures, attempt to clear a soft fault

prior to returning the PCTU PCB for repair. The

correct procedure for this is to reinstall the PCTU,

perform the initialization procedure, and then re-

program the system as necessary to test for the

fault. If the fault returns after these procedures are

performed, tag the defective PCTU and return it for

repair.

6

POWER SUPPLY

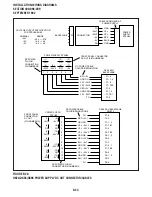

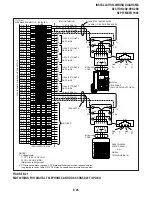

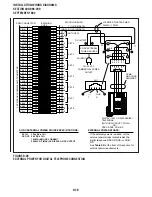

6.01 If a DC power fault is detected, all PCBs

should be disconnected from the backplane

connectors to eliminate them as the cause of the

power problem. The Power Supply Test Procedure

in Paragraph 3, section 400-096-205, Installation,

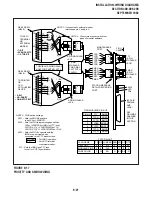

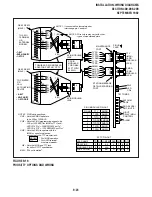

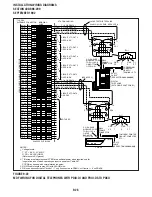

FIGURE 2—BACKPLANE CONNECTORS P1 (DK24), P1 & P4 (DK56/96)

BACKPLANE

P1

FG

-24V2

-5V

-24V1

+5V

DG

CONNECTOR

GRN

YEL

YEL

RED

BLUE

GRN

CABLE FROM REAR

OF POWER SUPPLY

PPSU-24

6

5

4

3

2

1

FG

Ð24V3

+5V1

Ð5V1

DG

DG

FG

Ð24V5

+5V2

Ð5V2

DG

DG

Ð24V1 TB1

Ð24V2 TB2

Ð24V4 TB3

DK96

DK56/96

6

5

4

3

2

1

Check between pins 1 and 2 (DG) and the desired voltage.

OBSERVE THE CORRECT POLARITY.

P1

P4

Summary of Contents for Strata DK 24

Page 2: ......

Page 10: ......

Page 12: ...INSTALLATION SYSTEM DESCRIPTION SECTION 400 096 202 SEPTEMBER 1992 ...

Page 42: ......

Page 72: ......

Page 102: ......

Page 110: ......

Page 144: ...INSTALLATION TELEPHONE SECTION 400 096 207 SEPTEMBER 1992 ...

Page 164: ......

Page 166: ...INSTALLATION PERIPHERALS SECTION 400 096 208 SEPTEMBER 1992 ...

Page 170: ......

Page 238: ...INSTALLATION WIRING DIAGRAMS SECTION 400 096 209 SEPTEMBER 1992 ...

Page 300: ......

Page 302: ...REMOTE ADMINISTRATION MAINTENANCE PROCEDURES SECTION 400 096 600 SEPTEMBER 1992 ...

Page 372: ......