DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

3-5

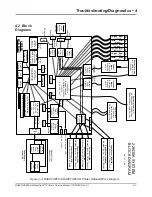

Theory • 3

3.3 Operating

Sequence

When the printer is either, “off line” (led is unlit) and the [test] button is de-

pressed, or the printer is “on line” (led is lit) and a valid address is received

from the computer, the belt drive motor will be energized. A belt, driven by

the motor, drives the belt drive roller assembly which in turn drives the media

belts.

The printer motor will be energized. The printer belt connects the printer mo-

tor to the transport roller and exit roller. The processor board will compare

the speed of the encoder on the transport roller to calculate the desired

speed.

The feed motor will be energized, and the feed rollers and feed belt will ro-

tate, pushing the bottom piece of media between the rollers and the “h” block

media separators. The frictional design of the “h” block media separator is to

restrict all but the bottom piece of media.

The feed roller moves the piece of media between the entry idler rollers and

the transport rollers. The speed differential between the transport rollers and

the feed rollers will create a gap between the moving pieces. The feeder

photo sensor assembly is energized as the piece of media is pushed out.

The transport roller continues to push the leading edge of the media into the

path of the printer sensor. When the leading edge of the media is detected

by the printer sensor assembly, two things occur:

• Position counting begins so that printing will occur at the preprogrammed

position on the media. This pre-programmed position is set in the ad-

dress layout or is controlled by the software driver.

• The media is captured between the exit roller and the exit idler roller

where it is ejected from the printer. In the DA95F, an exit sensor captures

the piece exit data.

This process is repeated until all the records in the file are printed.