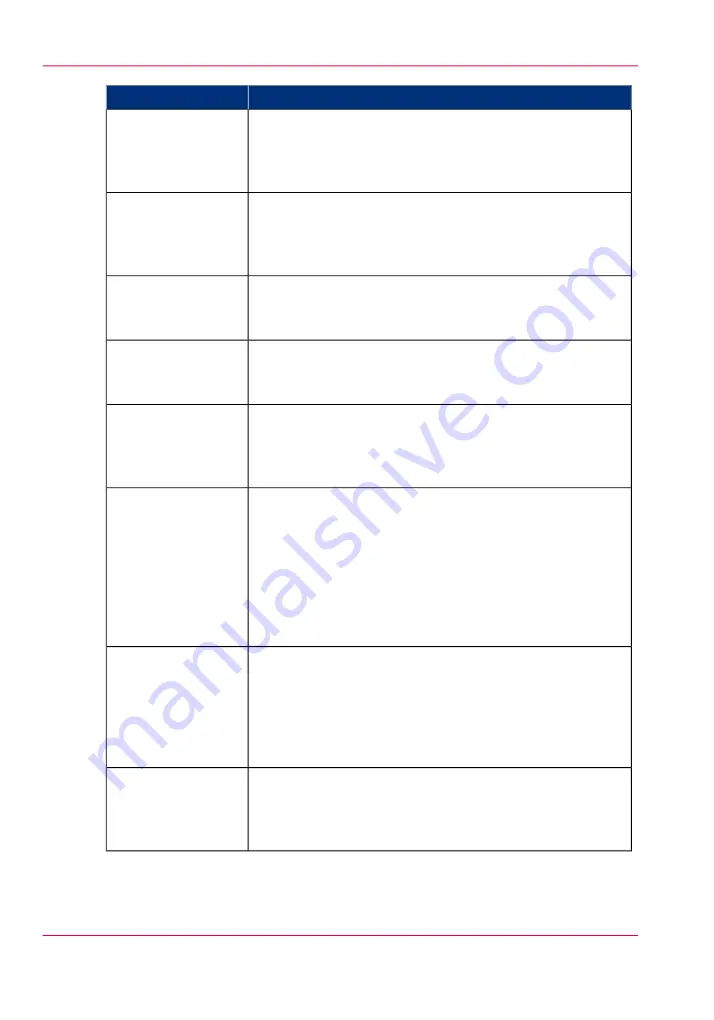

Function

Component

The three vacuum zone control handles determine which of

the three print zones on the printer table will have vacuum

applied when the vacuum pump is switched on. The vacuum

zones are opened or closed by the handles.

3) Vacuum Zone

Control

A vacuum foot pedal switch is provided to facilitate the process

of securing the media on the vacuum table. The foot pedal

toggles the table vacuum on/off. The vacuum must be turned

on prior to starting a print.

4) Vacuum Table

Foot Pedal

A bleed valve can be adjusted to reduce or increase the amount

of vacuum suction on the media. Less vacuum reduces artifacts

caused by suction when imaging on flexible media.

5) Vacuum Bleed

Valve & Gague

The print button is located at the corner where media is

loaded on the table. After positioning the media and activating

the vacuum, press the button to start the print.

6) Print Button

The green colored beacon light is mounted on the top surface

of the carriage. The purpose of the light is to indicate basic

machine status to the operator. See the table after this section

for the significance of the different states of the light.

7) Printer Status

Light

If a situation requires an immediate shutdown of all printer

activity, press one of the three Emergency Stop buttons. To

recover from an emergency shutdown, resolve the problem

that prompted the shutdown and then release the Emergency

Stop by twisting it slightly clockwise. Restoring functionality

to all disabled systems can only occur through an operator

command at the Control Station. See below for the parts of

the hardware interface affected by an Emergency Stop.

8) Emergency Stops

Daily printhead maintenance consists of an ink purge and

suction cleaning of the printheads. The maintenance station

cover is slid open to access the printheads and the suction

nozzle. The maintenance station is located under the carriage.

Maintenance is performed when the carriage is parked at the

end of the gantry.

9) Maintenance Sta-

tion

The coolant reservoir is mounted in the carriage. The operator

has the ability to refill the reservoir and to monitor the level

of coolant at this location. See Maintenance section for instruc-

tions.

10) Coolant Reser-

voir

Chapter 4 - How to Navigate the User Interface

46

Operator Interface Hardware

Summary of Contents for Arizona 550 GT

Page 1: ...Océ Arizona 550 GT User Manual Version 1 0 Revision B Océ User Manual ...

Page 6: ...6 Contents ...

Page 7: ...Chapter 1 Introduction ...

Page 15: ...Chapter 2 Product Overview ...

Page 19: ...Chapter 3 Safety Information ...

Page 43: ...Chapter 4 How to Navigate the User Interface ...

Page 71: ...Chapter 5 How to Operate the Océ Arizona 550 GT ...

Page 101: ...Chapter 6 How to Operate the Roll Media Option ...

Page 135: ...Chapter 7 How to Use the Static Suppression Upgrade Kit ...

Page 139: ...Chapter 8 How to Work With White Ink ...

Page 179: ... 145 Parameters Chapter 8 How to Work With White Ink 179 How to Use Media Models ...

Page 196: ...Chapter 8 How to Work With White Ink 196 How to Create and Use Quick Sets ...

Page 197: ...Chapter 9 Ink System Management ...

Page 205: ...Chapter 10 Error Handling and Trou bleshooting ...

Page 209: ...Chapter 11 Printer Maintenance ...