ANEXO 1. SOFTWARE ESA S630

A38

- Enter the radius of the rolling (60.0) in the field “R”, touching with a finger on the field.

- Press

[Ok].

- Enter the length of the rolling pitch you want to obtain in the field “P”, touching with a finger on the field.

- Press

[Ok],

the next length will be drawn in automatic mode; the length that the data refer to will be

highlighted.

- Enter the length corresponding to the last length to be drawn (30.0) in the field “I” , touching with a finger

on the field.

- Press

[Ok],

the drawing has now been completed.

How to execute a Dutch Folding (hemming)

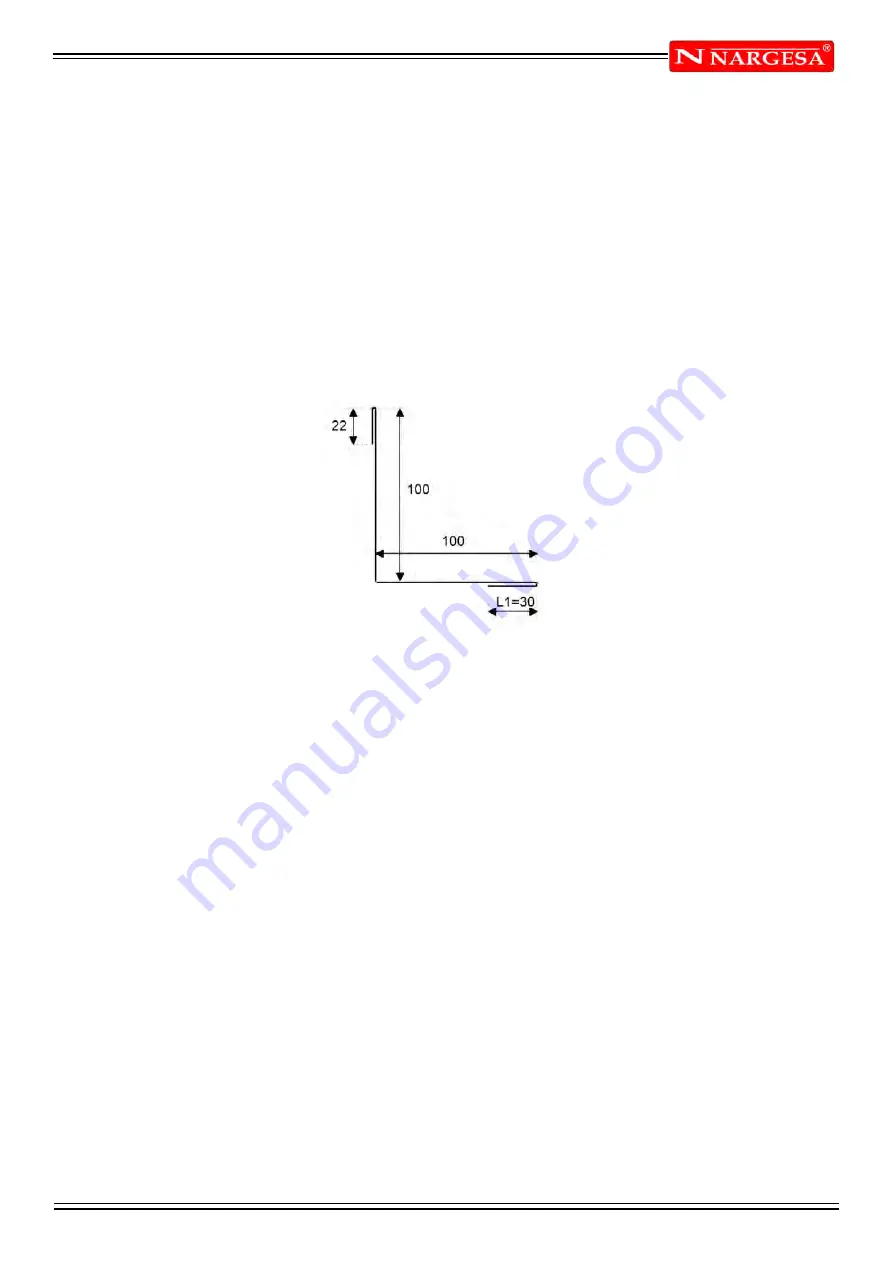

Let's suppose we have to draw the piece illustrated in the figure 32:

Figure 32 Example of Dutch Folding bend to be drawn

The cursor is located in the field “I” of the window for the polar setting of the drawing data.

- Enter the length of side L1 to be hemmed (30.0) in the field “l” , touching with a finger on the field.

- Press

[Ok].

- Press

[Dutch Folding].

- Enter the intermediate Dutch folding angle (e.g.: 45.0°) in the

“

alpha

”

field, touching with a finger on the

field.

- Press

[Ok],

the next length will be drawn in automatic mode; the length the data refer to will be highlighted.

- Enter the length of the side (100.0) in the field “I”, touching with a finger on the field.

- Press

[Ok],

the cursor will move onto the field

“

alfa

”

for setting the angle compared to the following length.

- Enter the value of the angle (-90.0°), touching with a finger on the field.

- Press

[Ok],

Enter the length of the side (100.0) in the field “I”, touching with a finger on the field .

- Press

[Ok].

- Press

[Dutch Folding].

- Enter the intermediate Dutch folding angle (e.g.: 45.0°) in the

alpha

field, touching with a finger on the field.

- Press

[Ok],

the next length will be drawn in automatic mode; the length the data refer to will be highlighted.

- Enter the length of the last side (22.0) in the field “I”, touching with a finger on the field. The drawing has

now been completed.

Summary of Contents for MP3003 CNC

Page 2: ...Thank you for choosing our machines www nargesa com...

Page 18: ...Annex 1 Software ESA S630...

Page 19: ......

Page 68: ...Annex 2 Technical data...

Page 69: ......

Page 71: ...ANEX 2 TECHNICAL DATA MP3003CNC B3 1 List of parts...

Page 72: ...ANEX 2 TECHNICAL DATA MP3003CNC B4...

Page 73: ...ANEX 2 TECHNICAL DATA MP3003CNC B5...

Page 74: ...ANEX 2 TECHNICAL DATA MP3003CNC B6...

Page 75: ...ANEX 2 TECHNICAL DATA MP3003CNC B7...

Page 76: ...ANEX 2 TECHNICAL DATA MP3003CNC B8...

Page 77: ...ANEX 2 TECHNICAL DATA MP3003CNC B9...

Page 78: ...ANEX 2 TECHNICAL DATA MP3003CNC B10...

Page 79: ...ANEX 2 TECHNICAL DATA MP3003CNC B11...

Page 80: ...ANEX 2 TECHNICAL DATA MP3003CNC B12 2 Hydraulic group...

Page 81: ...ANEX 2 TECHNICAL DATA MP3003CNC B13...

Page 82: ...ANEX 2 TECHNICAL DATA MP3003CNC B14...

Page 83: ...ANEX 2 TECHNICAL DATA MP3003CNC B15 3 Upper cylinder...

Page 84: ...ANEX 2 TECHNICAL DATA MP3003CNC B16...

Page 85: ...ANEX 2 TECHNICAL DATA MP3003CNC B17 4 Main cylinder...

Page 86: ...ANEX 2 TECHNICAL DATA MP3003CNC B18...

Page 87: ...ANEX 2 TECHNICAL DATA MP3003CNC B19 5 Electric box...

Page 88: ...ANEX 2 TECHNICAL DATA MP3003CNC B20 6 Control panel box...

Page 89: ...ANEX 2 TECHNICAL DATA MP3003CNC B21 7 Electric maps...

Page 90: ...ANEX 2 TECHNICAL DATA MP3003CNC B22...

Page 91: ...ANEX 2 TECHNICAL DATA MP3003CNC B23...

Page 92: ...ANEX 2 TECHNICAL DATA MP3003CNC B24...

Page 93: ...ANEX 2 TECHNICAL DATA MP3003CNC B25...

Page 94: ...ANEX 2 TECHNICAL DATA MP3003CNC B26...

Page 95: ...ANEX 2 TECHNICAL DATA MP3003CNC B27...

Page 96: ......

Page 98: ...Annex 3 Laser devices...

Page 99: ......

Page 109: ...ANNEX 3 LASER DEVICE C11 15 List of parts right laser...

Page 110: ...ANNEX 3 LASER DEVICE C12...

Page 111: ...ANNEX 3 LASER DEVICE C13...