[

VII

Control ]

- 87 -

HWE10060

GB

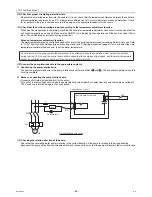

Emergency Operation Mode

-11- Multiple system control

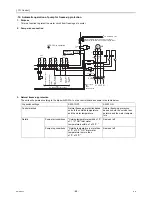

1. Electrical wiring diagram

Circuit board

Circuit board

Unit

(SUB circuit)

Unit

(MAIN circuit)

Circuit board

Circuit board

Unit

(SUB circuit)

Unit

(MAIN circuit)

External water

temperature sensor

Sub unit

Circuit board

Circuit board

Unit

(SUB circuit)

Unit

(MAIN circuit)

Sub unit

Main unit

M-NET cable

Field-supplied dry contact

switch/relay or remote controller

( * ) Main/Sub units and switch settings

SW2-8

( Use of external water temperature sensor)

SW2-9

( Multiple system)

Main unit (Unit to which the external

water temperature sensor is connected.)

ON

ON

Sub unit

OFF

ON

2. Water piping system configuration

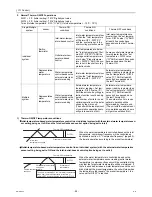

a. Changing the number of units to go into operation and changing the startup sequence of the units

(controlled by the main unit)

b. Operation control based on the compressor frequency (Each unit controls its own frequency.)

External water temperature sensor

(ex) Attached to the outlet

The main unit will determine the Tshs (the target outlet water temperature)

for each sub unit as well as the number of units to put into operation as

explained under item a below.

The target outlet water temperature of each unit will be

set as Tshs, and the water temperature is controlled

based on the compressor frequency. (See item b below.)

Preset water temperature (tshs)

Check interval : Variable between 1 and 5

DIFF2 : Differential (Variable between 0 and 8 K)

1) One unit will stop when the external water temperature meets the following formula: External water temperature ≤

[Set temperature (Tshs)] + [DIFF 2 value divided by 2].

If two or more units are operating at the same frequency, the one with more hours of cumulative operation hours will be stopped first.

2) One unit will go into operation when the external water temperature meets the following formula: External water temperature ≤

[Set temperature (Tshs)] - [DIFF 2 value divided by 2].

The unit with shorter cumulative operation hours will go into operation first.

The cumulative operation hours of a given unit is determined by the cumulative operation hours of the compressor with more hours

than the other compressor.

Each unit increases or decreases the compressor frequency based on the difference between the preset and the current water

temperatures.

The frequency of the compressor is adjusted to a range between 50 and 70 Hz to optimize operation efficiency.

Only when all units are under the Thermo-ON condition, the operating frequency may exceed 70 Hz.

Sub unit

Sub unit

Main unit

Circuit board

Circuit board

Circuit board

Summary of Contents for CAHV-P500YA-HPB

Page 1: ...Service Handbook Service Handbook CAHV P500YA HPB Model 2011 HOT WATER HEAT PUMP ...

Page 7: ...CONTENTS HWE10060 GB ...

Page 9: ... 2 HWE10060 GB ...

Page 19: ... 12 HWE10060 GB ...

Page 37: ... 30 HWE10060 GB ...

Page 46: ... 39 HWE10060 GB IV Remote Controller 1 Using the Remote Controller 41 2 Function Settings 46 ...

Page 47: ... 40 HWE10060 GB ...

Page 55: ... IV Remote Controller 48 HWE10060 GB ...

Page 56: ... 49 HWE10060 GB V Electrical Wiring Diagram 1 Electrical Wiring Diagram 51 ...

Page 57: ... 50 HWE10060 GB ...

Page 61: ... V Electrical Wiring Diagram 54 HWE10060 GB ...

Page 63: ... 56 HWE10060 GB ...

Page 67: ... VI Refrigerant Circuit 60 HWE10060 GB ...

Page 69: ... 62 HWE10060 GB ...

Page 101: ... VII Control 94 HWE10060 GB ...

Page 103: ... 96 HWE10060 GB ...

Page 109: ... VIII Test Run Mode 102 HWE10060 GB ...

Page 111: ... 104 HWE10060 GB ...

Page 155: ... IX Troubleshooting 148 HWE10060 GB ...

Page 156: ... 149 HWE10060 GB X Attachments 1 R407C saturation temperature table 151 ...

Page 157: ... 150 HWE10060 GB ...

Page 159: ... X Attachments 152 HWE10060 GB ...