[

IX

Troubleshooting ]

- 127 -

HWE10060

GB

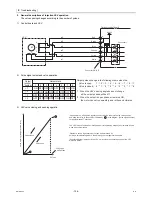

(1) Judgment methods and possible failure mode

Malfunction

mode

Judgment method

Remedy

Microcomputer

driver circuit fail-

ure

Disconnect the control board connector and connect

the check LED as shown in the figure below.

Pulse signal is output for 17 seconds when the main

power is turned on.

If there is any LED that remains unlit or remains lit,

there is a problem with the drive circuit.

When the drive circuit has a

problem, replace the control

board.

LEV mechanism

is locked

If the LEV is locked, the drive motor runs idle, and

makes a small clicking sound.

When the valve makes a closing and opening sound,

the valve has a problem.

Replace the LEV.

Disconnected or

short-circuited

LEV motor coil

Measure resistance between the coils (red - white, red

-orange, brown - yellow, brown - blue) using a tester.

They are normal if resistance is 150ohm 10%.

Replace the LEV coils.

Measure resistance between the coils (red - white, red

-orange, brown - yellow, brown - blue) using a tester.

They are normal if resistance is 46ohm 3%.

Replace the LEV coils.

Faulty wire con-

nections in the

connector or

faulty contact

1.

Check for loose pins on the connector and check

the colors of the lead wires visually

Check the continuity at the

points where an error occurs.

2.

Disconnect the control board's connector and

conduct a continuity check using a tester.

6

5

4

3

2

1

resistance

LED

resistance:0.25W 1k

Ω

LED:15VDC 20mA more

Summary of Contents for CAHV-P500YA-HPB

Page 1: ...Service Handbook Service Handbook CAHV P500YA HPB Model 2011 HOT WATER HEAT PUMP ...

Page 7: ...CONTENTS HWE10060 GB ...

Page 9: ... 2 HWE10060 GB ...

Page 19: ... 12 HWE10060 GB ...

Page 37: ... 30 HWE10060 GB ...

Page 46: ... 39 HWE10060 GB IV Remote Controller 1 Using the Remote Controller 41 2 Function Settings 46 ...

Page 47: ... 40 HWE10060 GB ...

Page 55: ... IV Remote Controller 48 HWE10060 GB ...

Page 56: ... 49 HWE10060 GB V Electrical Wiring Diagram 1 Electrical Wiring Diagram 51 ...

Page 57: ... 50 HWE10060 GB ...

Page 61: ... V Electrical Wiring Diagram 54 HWE10060 GB ...

Page 63: ... 56 HWE10060 GB ...

Page 67: ... VI Refrigerant Circuit 60 HWE10060 GB ...

Page 69: ... 62 HWE10060 GB ...

Page 101: ... VII Control 94 HWE10060 GB ...

Page 103: ... 96 HWE10060 GB ...

Page 109: ... VIII Test Run Mode 102 HWE10060 GB ...

Page 111: ... 104 HWE10060 GB ...

Page 155: ... IX Troubleshooting 148 HWE10060 GB ...

Page 156: ... 149 HWE10060 GB X Attachments 1 R407C saturation temperature table 151 ...

Page 157: ... 150 HWE10060 GB ...

Page 159: ... X Attachments 152 HWE10060 GB ...