-278-

ENGINE MANAGEMENT SYSTEM

- 278 -

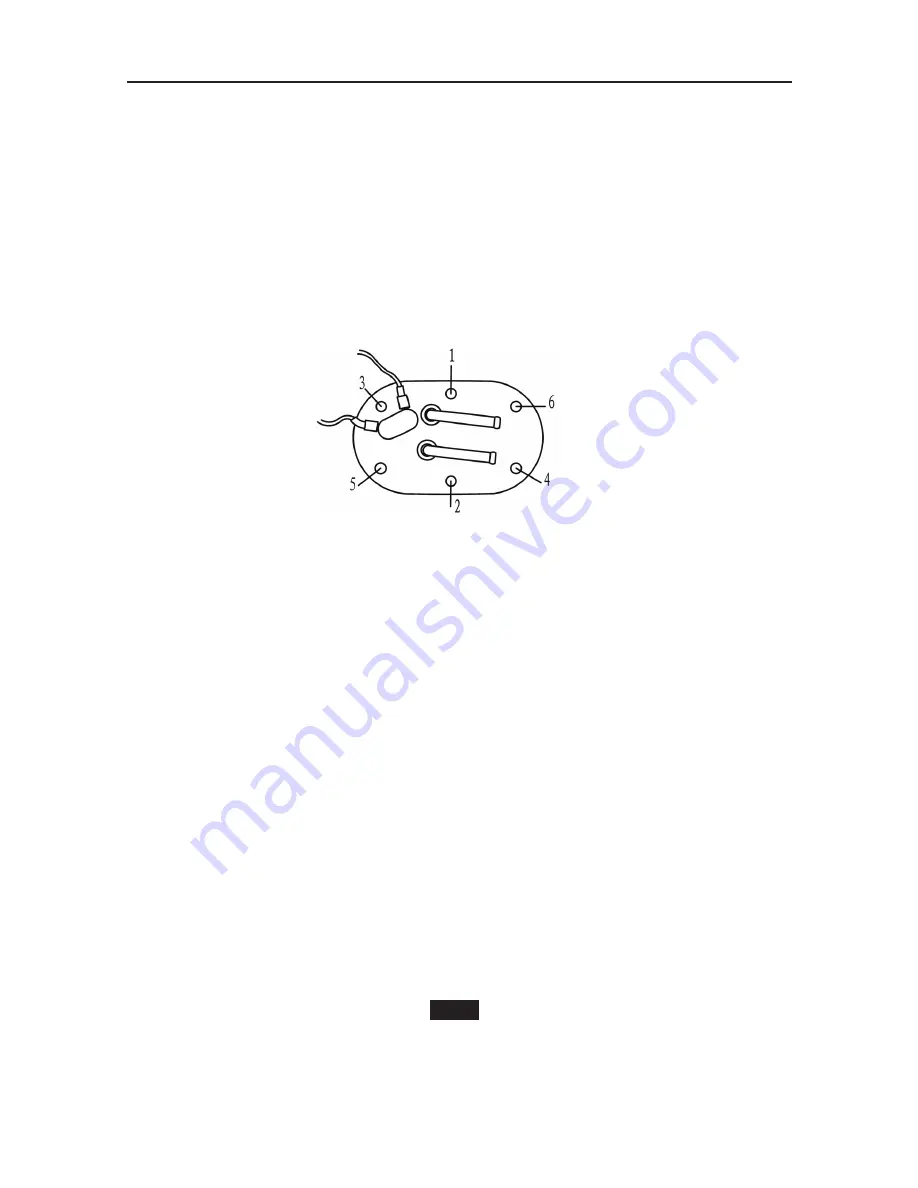

Place the bolts on module cover and tighten the bolts gradually in star pattern sequence to

apply equal compression on gasket. It is shown in figure as below. Bolt Tightening Torque:

3~4 Nm.

Fuel module is installed with special bolts (step bolts). Use designated bolts only. Follow

the tightening torque and tightening sequence instruction.Over torque and

miss-sequence can cause unequal compression of gasket and leakage.

Install the fuel tank to vehicle.

Connect for fuel hoses with suitable hose clamps.

Connect fuel module coupler.

Follow “Fuel Leakage Check Procedure’ to check any leakage before the engine is started

。

Mounting Bolts – Star Tightening Pattern

5. Pressure Regulator Assembly Replacement:

Remove the regulator retainer from module.

Apply gradual pull force on retainer to avoid any personal injury due to spring action of

retainer.

Take out the pressure regulator assembly from module.

Do not hit/ damage on the regulator dome and crimping portion.

Lubricate the O-rings in new pressure regulator assembly with recommended lubrication

oils as mentioned in Table no: 3. Lubrication oil is applied only for ease of regulator

assembly.

Make sure that 2 O-rings (one is bigger diameter the other is smaller diameter) are

assembled in pressure regulator.

Place the pressure regulator on module at regulator pod. Push the regulator gently in the

pod.

Do not hit/ damage on the regulator dome and crimping portion. This will disturb the

pressure setting.

Assemble the retainer on the regulator pod

Replace the gasket, module with new gasket provided in the kit.

6. Fuel Pressure Relief Procedure:

NOTE

This work must not be done when engine

is hot. If done so, it may cause adverse effect to

catalyst (if equipped)

ENGINE MANAGEMENT SYSTEM

- 279 -

After making sure that engine is cold, relieve fuel pressure as follows.

Place vehicle gear in ‘Neutral’.

Disconnect fuel module electrical coupler from vehicle harness.

Start engine and run till it stops due to lack of fuel. Repeat ignition key ON and OFF for 2 ~ 3

times of about 3 seconds each time to relieve fuel pressure in lines. Fuel Connections are

now safe for servicing.

Upon the completion of servicing, Connect Fuel Module Connector to Vehicle Harness.

7. Fuel Leakage Check Procedure:

After performing any service on fuel system, check to make sure that there are no fuel leakages

as below.

Fill about 3 ~ 5 liters of fuel in tank.

Turn Ignition key to ON position for 3 seconds (to operate fuel pump) and then turn to OFF

position. Repeat this for 3 ~ 4 times to apply fuel pressure in fuel lines.

In this state, check to see that there are no fuel leakage from any part of fuel system (Fuel

Tank, Hoses, Hose Joints, etc)

8. Handling – DOs and DONTs:

FUEL MODULE HANDLING

ACTION REASON

DO NOT:

Drop Fuel Module on Floor

Could cause internal damage to Fuel

Pump.

DO NOT

:

Run Fuel Pump Dry (without fuel

at pump inlet/ strainer) ensure atleast 3

litres of gasoline is present in the fuel tank

Caused internal damage to Fuel Pump

DO NOT

:

Damage the strainer during

servicing, insertion of fuel module in fuel

tank

Contamination enters fuel pump thru

damaged strainer damages the Fuel

Pump

DO NOT

:

Disassemble Fuel Pump and

regulator internal parts out side Delphi

premises.

DO NOT:

Do any adjustments on pressure

regulator and pump except for

replacement.

Warranty void.

DO NOT

:

Use module harness for hold/

carry fuel module.

DO NOT:

Pull Wiring Harness in vertical

direction to module cover

Wiring Harness Breakage/ Fuel Pump

Power disconnection

DO NOT

:

Use damaged/ distorted hose

clamps.

Can cause fuel seepage/ leakage.

Summary of Contents for HS200UTV

Page 3: ......

Page 15: ......

Page 94: ... 79 SPECIFICATIONS 79 HYDROGRAPHIC CHART Hydrographic chart Pressure ...

Page 95: ... 80 SPECIFICATIONS 80 LUBRICATION OIL WAY LUBRICATION OIL WAY Pressure splashing oil ...

Page 248: ... 233 CHASSIS 233 Fuel tank cap Remove the fuel tank cap by turning it counterclockwise ...

Page 263: ... 248 ...

Page 304: ... 289 ...

Page 305: ... 290 ...

Page 306: ... 291 ...

Page 307: ... 292 ...

Page 308: ... 293 ...

Page 309: ... 294 ...

Page 310: ... 295 ...

Page 311: ... 296 ...