-134-

ENGINE

- 134 -

1

、

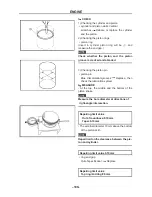

CHECK

• valve sealing

Leakage at the valve seat

Check the valve

face, valve seat and valve seat width.

a. Pour a clean solvent into the intake and

①

exhaust ports.

b. Check that the valve seals properly. There

should be no leakage at the valve seat

②

.

• valve face

Pitting/wear

Grind the face.

• valve stem end

Mushroom shape or diameter larger than the

body of the stem

Replace.

• valve seats

Pitting/wear

Reface the valve seat.

2

、

MEASURE:

1).Measure:

• The valves surface width

Repairing limit value 2.0mm

• stem-to-guide clearance

Stem-to-guide clearance = valve guide

inside diameter – valve stem diameter

NOTE:

If the mating surface is coarse, corrode or

cannot contact with valve seat normally,

replace it.

Stem-to-guide clearance repairing limit

value

Intake:0.08mm Exhaust:0.10mm

• margin thickness (a)

Out of specification

Replace.

Margin thickness

Intake:2 mm

Exhaust:2.2 mm

• valve stem runout

Out of specification

Replace.

Runout limit 0.01 mm

ENGINE

- 135 -

NOTE:

• When installing a new valve always replace

the guide.

• If the valve is removed or replaced always

replace the oil seal.

• The valve seat surface width

Out of specification

Reface the valve seat.

Repairing limit value

2.0mm

a. Install the valve into the cylinder head.

b. Press the valve through the valve guide and

onto the valve seat to make a clear pattern.

c. Measure the valve seat width. Where the

valve seat and valve face made contact, blueing

will have been removed.

• Valve spring free length

• Valve spring squareness

Out of specification

Replace.

Valve spring free length

Intake:44.9mm Exhaust44.9mm

Valve spring squareness

Intake:1.60mm Exhaust 1.60mm

• compressed spring force(a)

Out of specification

Replace.

(b) Installed length

Compressed spring force

Intake: 470 N at 24.5 mm

Exhaust: 270 N at 31.0 mm

2). Remove:

• valve guide

NOTE:

To ease guide removal, installation and to

maintain correct fit, heat the cylinder head to

100 °C (212 °F) in an oven.

a. Install the new valve guide using a valve guide

remover

①

and valve guide installer

②

.

b. After installing the valve guide, bore the

valve guide using a valve guide reamer

③

to obtain proper stem-to-guide clearance.

Summary of Contents for HS200UTV

Page 3: ......

Page 15: ......

Page 94: ... 79 SPECIFICATIONS 79 HYDROGRAPHIC CHART Hydrographic chart Pressure ...

Page 95: ... 80 SPECIFICATIONS 80 LUBRICATION OIL WAY LUBRICATION OIL WAY Pressure splashing oil ...

Page 248: ... 233 CHASSIS 233 Fuel tank cap Remove the fuel tank cap by turning it counterclockwise ...

Page 263: ... 248 ...

Page 304: ... 289 ...

Page 305: ... 290 ...

Page 306: ... 291 ...

Page 307: ... 292 ...

Page 308: ... 293 ...

Page 309: ... 294 ...

Page 310: ... 295 ...

Page 311: ... 296 ...