-166-

ENGINE

- 166 -

3

、

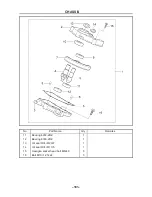

INSTALL

1). Assembling the shift fork

• shifting yoke

Ⅱ①

•H shifting fork

②

•L shifting fork

③

•HR gear dpring

④

•L gear spring

⑤

•R shifting fork

⑥

•shifting fork I

⑦

2). Installing the shift levers

• Variable speed drum

①

• Shift arm components

②

NOTE:

When installing the shift lever 1, align the

punch mark (a) on the shift lever 1 with the

punch marks (b) on the shift lever 2.

3). Assembling the oil pump

• inner rotor

• outer rotor

• oil pump shaft

(with the recommended lubricant)

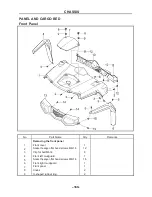

CHASSIS

- 167-

MALFUNCTION INSPECTION

Appearance malfunction inspection

No. Phenomenon

Measure

1 Plastic cover damaged

1. Replace new plastic cover.

2. Check whether installation supporter deformed, repairing

or re-painting is needed before replacing new plastic cover.

3. Re-paste decals and re-rivet warning labels.

2 Bumper damaged

1. Replace new bumper.

2. Check whether installation supporter deformed or

damaged, repairing or re-painting is needed before

replacing new bumper.

3

Frame toe-board damaged

1. Replace new frame toe-board.

2. Check plastic cover whether deformed or damaged,

repairing deformed or damaged plastic cover.

4 Warning labels

Replace damaged and vague warning labels

Brake system malfunction inspection

No. Phenomenon

Measure

1 Locked braking system

1. Check whether brake disc plates deformed.

2. Check whether hydraulic cylinder of brake clamp locked

or brake clamp assembly parts deformed.

2 Brake performance degressive

1. Check whether disc plates abrasion exceeded limits.

2. Check whether brake shoe of clamp abrasion exceeded

limits or polluted by friction material such as oil.

3

、

Check whether the oil cup of brake fluid lack oil.

3

Grinding noises emerged from

front brake or brake plate

become red during drive due

to superheat.

1. Check whether brake plate deformed.

2. Check whether hydraulic cylinder of brake clamp locked

or brake clamp assembly parts deformed.

4

Grinding noises emerged from

rear brake or brake plate

become red during drive

1. Check whether brake plate deformed.

2. Check whether hydraulic cylinder of brake clamp locked

or brake clamp assembly parts deformed.

3. Check whether rear brake clamp parking institution

running flexible or return accurately.

5

Off tracking by braking at

high-speed

1. Check whether front brake power deviation from left and

right is within specified scope.

2. Check whether front brake power degressive caused to

rear wheel locked before front wheel in brake process.

3. Check whether left and right absorber spring force

deviation is exceeded specified value.

4. Check whether front wheel and front wheel axle nut

loosen or damaged.

Summary of Contents for HS200UTV

Page 3: ......

Page 15: ......

Page 94: ... 79 SPECIFICATIONS 79 HYDROGRAPHIC CHART Hydrographic chart Pressure ...

Page 95: ... 80 SPECIFICATIONS 80 LUBRICATION OIL WAY LUBRICATION OIL WAY Pressure splashing oil ...

Page 248: ... 233 CHASSIS 233 Fuel tank cap Remove the fuel tank cap by turning it counterclockwise ...

Page 263: ... 248 ...

Page 304: ... 289 ...

Page 305: ... 290 ...

Page 306: ... 291 ...

Page 307: ... 292 ...

Page 308: ... 293 ...

Page 309: ... 294 ...

Page 310: ... 295 ...

Page 311: ... 296 ...