-238-

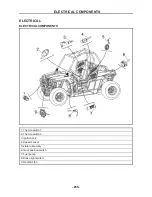

ELECTRICAL COMPONENTS

- 238 -

Checking the switch continuity

Refer to “CHECKING THE SWITCH” and check for continuity between lead terminals. Poor connection,

no continuity

Correct or replace.

*

The coupler locations are circled.

1. Parking brake switch

2. Brake light switch

3. Main switch

4. Light switch assy.

5. Distance light switch

6. Emergency lamp switch

7.Turning light switch

8. Windlass controler switch

ELECTRICAL COMPONENTS

- 239 -

IGNITION SYSTEM

CIRCUIT DIAGRAM

(

See 291 page

)

CHECKING THE BULBS AND BULB

SOCKETS

Check each bulb and bulb socket for damage or

wear, proper connections, and also for continuity

between the terminals

Damage/wear

Repair or replace the bulb, bulb

socket or both.

Improperly connected

Properly connect.

Incorrect continuity reading

Repair or replace

the bulb, bulb socket or both.

WARNING

:

Since the bulb gets extremely hot, keep

flammable products and your hands away from

the bulb until it has cooled down.

CAUTION:

• Be sure to hold the socket firmly when

removing the bulb. Never pull the lead,

otherwise it may be pulled out of the terminal

in the coupler.

• Avoid touching the glass part of the bulb to

keep it free from oil, otherwise the

transparency of the glass, the life of the bulb

and the luminous flux will be adversely

affected. If the bulb gets soiled, thoroughly

clean it with a cloth moistened with alcohol

or lacquer thinner.

Summary of Contents for HS200UTV

Page 3: ......

Page 15: ......

Page 94: ... 79 SPECIFICATIONS 79 HYDROGRAPHIC CHART Hydrographic chart Pressure ...

Page 95: ... 80 SPECIFICATIONS 80 LUBRICATION OIL WAY LUBRICATION OIL WAY Pressure splashing oil ...

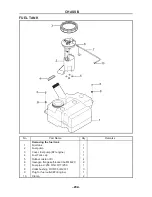

Page 248: ... 233 CHASSIS 233 Fuel tank cap Remove the fuel tank cap by turning it counterclockwise ...

Page 263: ... 248 ...

Page 304: ... 289 ...

Page 305: ... 290 ...

Page 306: ... 291 ...

Page 307: ... 292 ...

Page 308: ... 293 ...

Page 309: ... 294 ...

Page 310: ... 295 ...

Page 311: ... 296 ...