36

The following procedures are performed less

frequently than daily or as needed.

NOTE:

YOUR HANDS SHOULD BE CLEANED

AND SANITIZED BEFORE YOU PERFORM

THE FOLLOWING PROCEDURES.

NOTE:

THE FOLLOWING PROCEDURES

REQUIRE APPROVED, SERVICEABLE AND

SANITIZED TOOLS AND BRUSHES.

CONTACT YOUR LOCAL DISTRIBUTOR FOR

RECOMMENDED SUPPLIES.

NOTE:

USE AN APPROVED CLEANER AND

SANITIZER FOR THE FOLLOWING

PROCEDURES. REFER TO

MANUFACTURER’S INSTRUCTIONS FOR

PROPER PREPARATIONS OF THESE

CLEANING AGENTS.

NOTE:

INSPECT ALL WEAR ITEMS AND

REPLACE IF NECESSARY.

NOTE:

OPERATE UNIT UNDER NORMAL

AMBIENT TEMPERATURES BETWEEN 60

AND 80 DEGREES FAHRENHEIT. UNIT

SHOULD NEVER BE EXPOSED TO

FREEZING TEMPERATURES.

Clean-In-Place (CIP) Procedure

The Clean-In-Place procedure should be

performed every 30 days to ensure that the

syrup passageways are free of any product

crystallization. The medium used for this

process must be an approved sanitizing product

mixed according to the product manufacturer’s

instructions.

This Clean-In-Place procedure is detailed in

four phases:

(1) Prep

(2) Flush

(3) Clean

(4) Reassemble

To ensure maximum results, the following

instructions should be completed in sequence

as stated. This will expose the system and

parts to the sanitizing medium for about 130

minutes.

CIP - Phase 1: Prep

1. Mix approved detergent with warm water

according to manufacturer’s instructions.

2. Ensure the Sanitizer Tank is filled with fresh

approved sanitizer solution according to

manufacturer’s instructions (no more than 2

days old. Use hot water for best sanitizing

results.

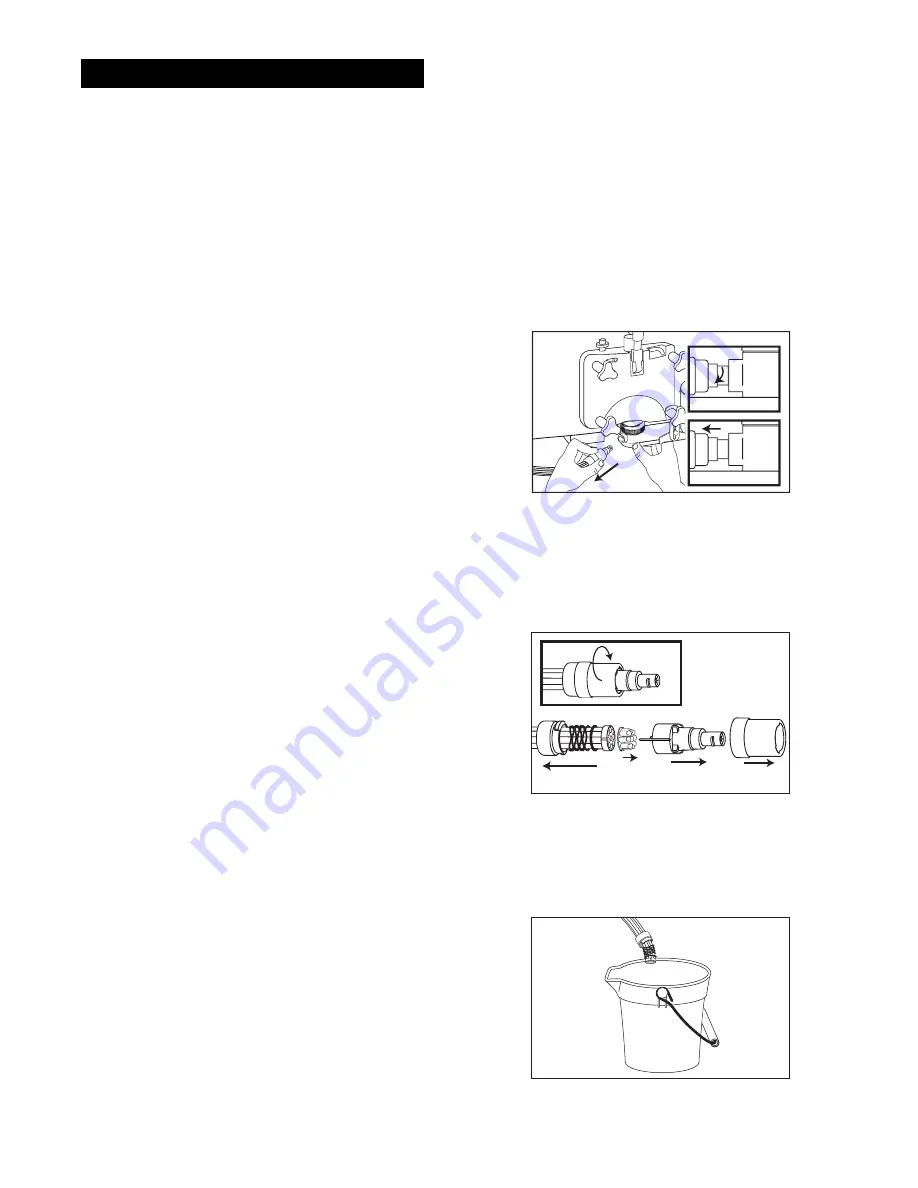

3. Rotate the 9-Tube Assembly coupler until it

unlocks and remove it from the Blending

Head syrup line opening.

26050

4. Unlock the Coupler Body by rotating it from

the Coupler Base. Remove the Coupler

Body, Syrup Line Manifold, and Duckbill

Check Valve from the 9-Tube Assembly.

Place these parts in detergent water.

26170

5. Place the end of the 9-Tube Assembly into

a container to catch the expelled syrup and

sanitizer solution during the rest of the

Clean-In-Place procedure.

26172

SCHEDULED MAINTENANCE

Summary of Contents for TS 80BLD

Page 4: ...3 PAGE INTENTIONALLY LEFT BLANK...

Page 7: ...6 General System Overview 1 3 7 9 8 6 4 5 26001 12 2 10 11 Figure 1...

Page 12: ...11 PAGE INTENTIONALLY LEFT BLANK...

Page 21: ...20 Spare Parts Kit 10 12 13 2 6 5 11 7 16 3 4 1 14 9 15 8 26007 Figure 7...