Operating Principles

Rev. A

2-29

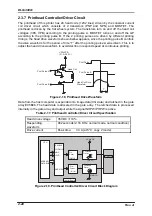

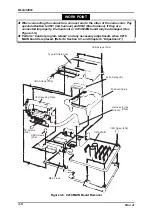

2.3.10 Paper Thickness Detecting Circuit

PG is detected by the paper thickness sensor which consists of the slit disc and the photo-

electric transfer element. See Table 2-19 and Figure 2-22 for the paper thickness sensor

specification and paper thickness sensor circuit block diagram, respectively.

Table 2-19. Paper Thickness Sensor Specification

Detecting method

Photo interrupt system

Power supply voltage

5 VDC

±

5%

Outputs

In 2 channels, TTL level

Minimum detecting thickness

0.008 mm

Detecting range

0 to 0.53 mm

+5V

PENCA

PENCB

T

PENCA

PENCB

E05B46

Gate Array

Paper Thickness Sensor

PHA

Condition

Figure 2-22. Paper Thickness Sensor Circuit Block Diagram

To determine the paper thickness, the printer monitors the waveforms output from the PG

sensor, as shown in Figure 2-22. “T” output for PHD shows a period of time in which 2-

chanel pulses PENCA and PENCB change for 180°. The printer counts the different

numbers of pulses output while the printhead moves from PG home position to the platen

surface and surface of the loaded paper to determine the paper thickness which

corresponds to the difference between 2 values. The numbers of pulses are counted in the

following order:

1. After the printer power is turned on, the PG home position is detected.

2. Distance between the printhead and platen surface is measured

While the printhead is moving from the PG home position toward the platen surface,

the waveform stays at a constant level and when that status exceeds for specified

period of time, the printer assumes that the printhead has reached the platen. The

PG motor consequently stops rotating and the numbers of the pulses output during

this operation is counted and the value is fed back to the CPU.

3. The printhead returns to the stand-by position.

4. The distance between the PG home position and loaded paper surface is measured in

the same procedure.

Paper thickness is determined for each paper loaded. The last values for the platen position

and PG before power-off are stored in the EEPROM and are no lost if the printer power is

turned off.

Summary of Contents for DLQ-3000 Minerva+

Page 1: ...EPSON 24 PIN DOT MATRIX PRINTER EPSON DLQ 3000 SERVICE MANUAL SEIKO EPSON CORPORATION 4008259 ...

Page 5: ...v REVISION SHEET Revision Issued Data Contents Rev A August 21 1997 First Release ...

Page 61: ...2 3 12 Other Sensor Circuits 2 31 ...

Page 160: ...Chapter 6 Maintenance 6 1 Maintenance 6 1 6 1 1 Lubrication and Adhesion 6 1 ...

Page 171: ...DLQ 3000 Rev A A 6 ...

Page 172: ...Appendix Rev A A 7 A 2 Circuit Diagrams Figure A 2 C210 MAIN Board Circuit Diagram 1 2 ...

Page 173: ...DLQ 3000 Rev A A 8 ...

Page 174: ...Appendix Rev A A 9 Figure A 3 C210 MAIN Board Circuit Diagram 2 2 ...

Page 175: ...DLQ 3000 Rev A A 10 ...

Page 177: ...DLQ 3000 Rev A A 12 Figure A 5 C124 PSB Board Circuit Diagram ...

Page 180: ...Appendix Rev A A 15 Figure A 8 C210 MAIN Board Component Layout 2 2 ...

Page 181: ...DLQ 3000 Rev A A 16 Figure A 9 C124 PSB Board Component Layout ...

Page 182: ...Appendix Rev A A 17 Figure A 10 C124 PSE Board Component Layout ...

Page 189: ...EPSON SEIKO EPSON CORPORATION ...