DLQ-3000+

Rev. A

4-2

4.2 Adjustment

4.2.1 Platen Gap (PG) Adjustment

Platen gap adjustment involves the following operations:

CR guide shaft parallelism adjustment

Platen gap reference value measurement and write operation

CR guide shaft parallelism adjustment

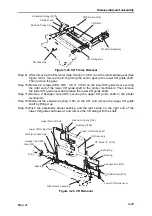

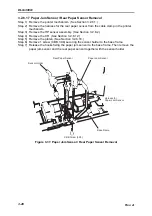

The parallelism adjust bushing rotates eccentrically toward the center of the location hole

in the right side frame, and it makes the right end of the CR guide shaft move toward or

from the platen roller as the parallelism adjust bushing rotates. The parallelism

adjustment is made to set the CR guide shaft parallel to the platen roller by turning the

parallelism adjust bushing. With this adjustment, the printhead moves in parallel with the

platen roller.

R i g h t S i d e F r a m e

C R G u i d e S h a f t

( L o w e r C R G u i d e S h a f t )

P l a t e n R o l l e r

P a r a l l e l i s m A d j u s t B u s h i n g

L o c a t i o n h o l e i n t h e r i g h t s i d e f r a m e

C R G u i d e S h a f t

( L o w e r C R G u i d e S h a f t )

Figure 4-1. CR Guide Shaft Parallelism Adjustment

PG reference value measurement and write operation

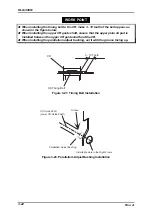

The PG reference value is measured by inserting 3 different thickness gages (0.39 mm,

0.55 mm and 0.72 mm) between the printhead and the platen roller. The PG reference

value measurement operation is required to compensate for physical unevenness which

is unique to each printhead. The PG reference value write operation writes the following

values into the EEPROM using the adjustment program:

Value “

α

” (1-digit number marked at the head nose side.)

3 values (

β

1,

β

2 and

β

3) measured with the thickness gauges

Perform CR guide shaft parallelism adjustment first, then the PG reference value

measurement and write operation.

Summary of Contents for DLQ-3000 Minerva+

Page 1: ...EPSON 24 PIN DOT MATRIX PRINTER EPSON DLQ 3000 SERVICE MANUAL SEIKO EPSON CORPORATION 4008259 ...

Page 5: ...v REVISION SHEET Revision Issued Data Contents Rev A August 21 1997 First Release ...

Page 61: ...2 3 12 Other Sensor Circuits 2 31 ...

Page 160: ...Chapter 6 Maintenance 6 1 Maintenance 6 1 6 1 1 Lubrication and Adhesion 6 1 ...

Page 171: ...DLQ 3000 Rev A A 6 ...

Page 172: ...Appendix Rev A A 7 A 2 Circuit Diagrams Figure A 2 C210 MAIN Board Circuit Diagram 1 2 ...

Page 173: ...DLQ 3000 Rev A A 8 ...

Page 174: ...Appendix Rev A A 9 Figure A 3 C210 MAIN Board Circuit Diagram 2 2 ...

Page 175: ...DLQ 3000 Rev A A 10 ...

Page 177: ...DLQ 3000 Rev A A 12 Figure A 5 C124 PSB Board Circuit Diagram ...

Page 180: ...Appendix Rev A A 15 Figure A 8 C210 MAIN Board Component Layout 2 2 ...

Page 181: ...DLQ 3000 Rev A A 16 Figure A 9 C124 PSB Board Component Layout ...

Page 182: ...Appendix Rev A A 17 Figure A 10 C124 PSE Board Component Layout ...

Page 189: ...EPSON SEIKO EPSON CORPORATION ...