Chapter 7

7-31

- 1 screw [1]

2) Detach the cover while pulling the separation claw holder [4] toward the

front.

- 2 screws [3]

F-7-95

Be careful not to break the separation claw.

7.10.19 Potential Sensor Unit

7.10.19.1 Outline

0015-4943

iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N

The potential sensor unit includes the following 4 parts:

- Potential control PCB

- Potential sensor

- Potential sensor relay harness (between the relay connector and the

potential control PCB)

- Potential sensor harness (between the potential sensor and the relay

connector)

Be sure to replace them at the same time.

7.10.19.2 Before Removing Potential Sensor Unit

0015-6700

iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N

1) Detach the front cover.

(page 10-13)

Reference[Removing the Front

Cover]

2) Detach the toner supply cover.

(page 10-14)

Reference[Removing the

Toner Supply Cover]

3) Remove the primary fan duct.

(page 10-29)

Reference[Removing Prima-

ry fan Duct]

7.10.19.3 Removing Potential Sensor Unit

0015-4952

iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N

1) Remove the potential sensor unit [3].

- 1 connector [1]

- 1 screw [2]

- Cable (free from the cable guide)

F-7-96

7.10.20 Charging Wire

7.10.20.1 Outline

0015-9965

iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N

The photosensitive drum is surrounded by 3 charging wires; the primary

charging wire, the pre-transfer charging wire, and the transfer/separation

charging wire.

These charging wires are newly adopted brown wires (0.06 mm in diameter).

Do not use a gold-plated wire that has been used in the past; otherwise, image

fault may occur.

Further, be sure to use a strengthened polishing pad (in a blue holder) as the

cleaning pad for the primary charging assembly and the transfer charging as-

sembly.

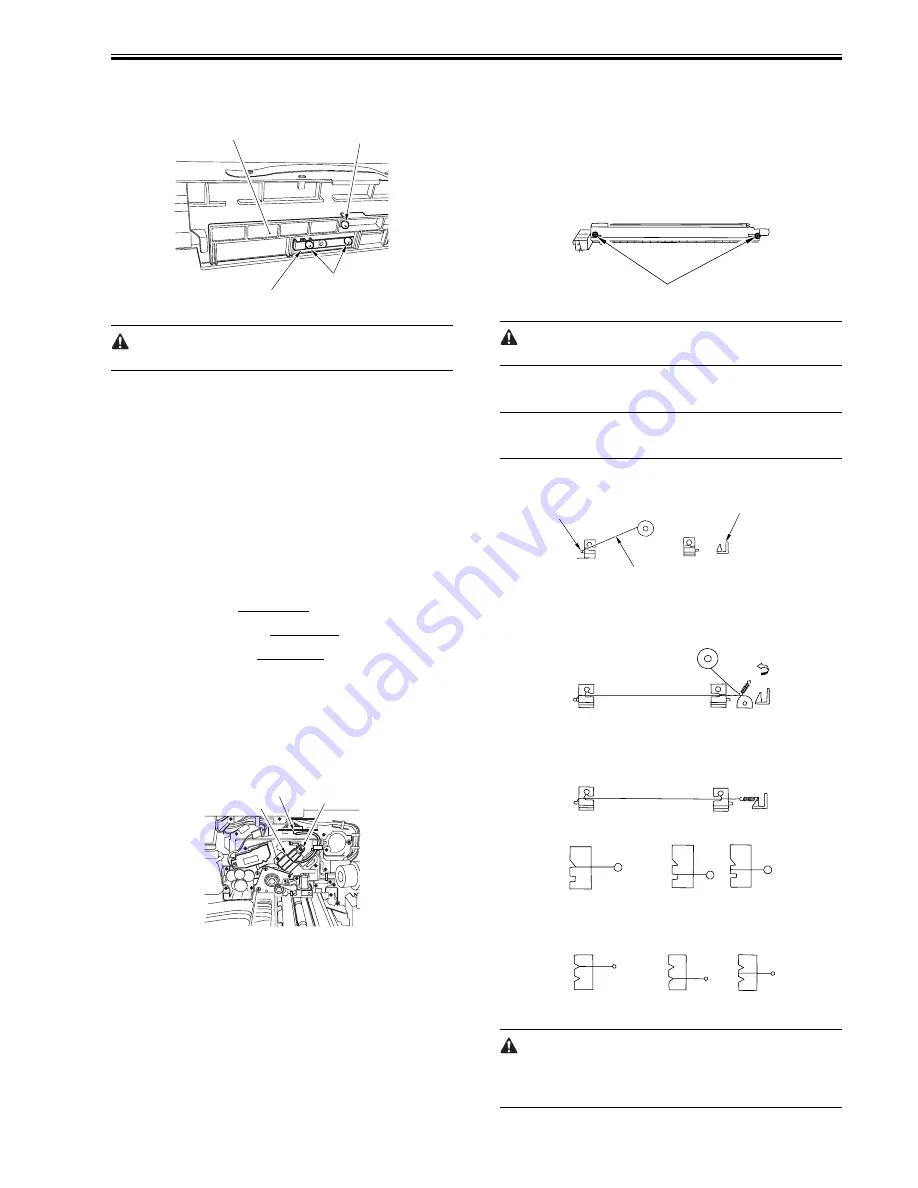

7.10.20.2 Routing Charging Wire

0015-9967

iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N

All charging wires (except the grid wire) are routed more or less in the same

way; the following cites the primary charging assembly.

1) Remove the shield plates (left, right) of the charging assembly. To prevent

deformation (deflection) in the primary charging assembly, be sure to

work separately for the left shielding plate and the right shielding plate

(do not loosen the screws [1] of both shielding plates at the same time.)

2) Remove the wire cleaner.

F-7-97

For other charging assemblies, remove the 2 covers.

3) Free a length of about 5 cm of the charging wire (0.06 mm in diameter)

from the charging wire reel, and form a loop at its end with a diameter of

about 2 mm.

MEMO:

To form a loop, wind the charging wire around a hex key once, and turn the

hex key 3 to 4 times; then, twist the charging wire.

4) Cut the end (excess) of the twisted wire.

5) Hook the loop on the stud.

F-7-98

6) At the rear, hook the charging wire on the charging wire positioning plate;

then, hook the charging wire tension spring on the charging wire where

indicated to the following figure.

F-7-99

7) Cut off the excess of the charging wire with nippers.

8) Pick the end of the charging wire tension spring with tweezers, and hook

it on the charging power supply electrode. In the case of the pre-transfer

charging assembly, hook the spring on the pin at the front.

F-7-100

F-7-101

Make sure the followings:

- The charging wire must not be bent or twisted.

- The charging wire must be fitted in the V-groove of the charging wire

positioning plate.

[2]

[1]

[4]

[3]

[1]

[2]

[3]

[1]

Charging electrode

(Rear)

(Front)

Charging wire

Reel

Stud

(Correct)

(Wrong)

Grid side

(Correct)

(Wrong)

Summary of Contents for iR5055

Page 1: ...Feb 29 2008 Service Manual iR5075 5065 5055 Series ...

Page 2: ......

Page 6: ......

Page 27: ...Contents 19 1 2 List of Solvents Oils 19 2 ...

Page 28: ...Contents ...

Page 29: ...Chapter 1 Introduction ...

Page 30: ......

Page 32: ......

Page 59: ...Chapter 2 Installation ...

Page 60: ......

Page 104: ...Chapter 2 2 42 F 2 156 2 1 ...

Page 105: ...Chapter 3 Basic Operation ...

Page 106: ......

Page 108: ......

Page 115: ...Chapter 4 Main Controller ...

Page 116: ......

Page 118: ......

Page 135: ...Chapter 5 Original Exposure System ...

Page 136: ......

Page 169: ...Chapter 6 Laser Exposure ...

Page 170: ......

Page 172: ......

Page 178: ......

Page 179: ...Chapter 7 Image Formation ...

Page 180: ......

Page 184: ......

Page 217: ...Chapter 8 Pickup Feeding System ...

Page 218: ......

Page 274: ......

Page 275: ...Chapter 9 Fixing System ...

Page 276: ......

Page 280: ......

Page 320: ......

Page 321: ...Chapter 10 External and Controls ...

Page 322: ......

Page 326: ......

Page 336: ...Chapter 10 10 10 F 10 7 2 Remove the check mark from SNMP Status Enabled ...

Page 337: ...Chapter 10 10 11 F 10 8 ...

Page 361: ...Chapter 11 MEAP ...

Page 362: ......

Page 364: ......

Page 409: ...Chapter 12 e maintenance imageWARE Remote ...

Page 410: ......

Page 412: ......

Page 421: ...Chapter 13 Maintenance and Inspection ...

Page 422: ......

Page 424: ......

Page 433: ...Chapter 14 Standards and Adjustments ...

Page 434: ......

Page 464: ......

Page 465: ...Chapter 15 Correcting Faulty Images ...

Page 466: ......

Page 468: ......

Page 496: ......

Page 497: ...Chapter 16 Self Diagnosis ...

Page 498: ......

Page 500: ......

Page 528: ......

Page 529: ...Chapter 17 Service Mode ...

Page 530: ......

Page 532: ......

Page 600: ......

Page 601: ...Chapter 18 Upgrading ...

Page 602: ......

Page 604: ......

Page 636: ...Chapter 18 18 32 F 18 59 2 Select the data to download F 18 60 3 Click Start ...

Page 638: ......

Page 639: ...Chapter 19 Service Tools ...

Page 640: ......

Page 642: ......

Page 645: ...Feb 29 2008 ...

Page 646: ......