Chapter 14

14-19

14.3 Scanning System

14.3.1 After Replacing the Reader Controller PCB

0015-9932

iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N

Be sure to generate the latest P-PRINT printout before replacing the reader

controller PCB.

- If you are initializing the RAM on the reader controller without replacing

the PCB

Using the SST, upload the backup data of R-CON; initialize the RAM, and

then download the data, thus eliminating the need for the following.

1) Using the SST, download the latest system software (R-CON).

2) Make the following selections in the service mode: COPIER > FUNC-

TION > CLEAR > R-CON. Then, press the OK key to execute RAM in-

itialization. Thereafter, turn off and then back on the main power.

3) Enter the appropriate settings for the following items in the service mode:

a. setting indicated on the service label (found behind the reader unit front

cover)

a-1. image read start position adjustment (X direction; in fixed reading

mode)

COPIER>ADJUST>ADJ-XY>ADJ-X

a-2 image read start position adjustment (Y direction; in fixed reading

mode)

COPIER>ADJUST>ADJ-XY>ADJ-Y

a-3 shading position adjustment (in fixed reading mode)

COPIER>ADJUST>ADJ-XY>ADJ-S

a-4 feeder mode main scanning position adjustment

COPIER>ADJUST>ADJ-XY>ADJ-Y-DF

a-5 ADF stream reading CCD reading position

COPIER>ADJUST>ADJ-XY>STRD-POS

a-6 density manipulating value adjustment

COPIER>ADJUST>CCD>DFCH-G2

COPIER>ADJUST>CCD>DFCH-G10

(After inputs it, execute COPIER>FUNCTION>DF-LNR)

The machine retains ADF-related service data in the RAM of its reader con-

troller.

ADF adjustment is necessary whenever you have replaced the reader con-

troller or initialized the RAM.

b. original stop position adjustment (X direction) (stream reading)

FEEDER>ADJSUT>DOCST

c. original feed speed (magnification) adjustment

FEEDER>ADUST>LA-SPEED

4) Make adjustments using the following service mode items:

a. ADF sensor sensitivity adjustment

FEEDER>FUNCTION>SENS-INT

b. tray width adjustment

FEEDER>FUNCTION>TRY-A4

FEEDER>FUNCTION>TRY-A5R

FEEDER>FUNCTION>TRY-LTR

FEEDER>FUNCTION>TRY-LTRR

c. white plate data adjustment

COPIER>FUNCTION>CCD>CCD-ADJ

d. ADF white level adjustment

COPIER>FUNCTION>CCD>DF-WLVL1

COPIER>FUNCTION>CCD>DF-WLVL2

Be sure to perform white plate data adjustment before performing ADF

white level adjustment.

After having made the foregoing adjustments, put the P-PRINT printout in

the service book case, replacing the previous P-PRINT printout.

14.3.2 When Replacing the CCD Unit

0015-9938

iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N

Perform the following steps after replacing the CCD unit.

1) Enter the correction values to be described on the label included in the

CCD unit (the 2 following items) in the service mode.

- COPIER > ADJUST > CCD > DFCH2G2

- COPIER > ADJUST > CCD > DFCH2G10

2) Transcribe the above correction values to the service label at the back of

the front cover of the host machine.

3) Execute the following in the service mode.

3-1) White plate data adjustment (COPIER > FUNCTION > CCD > CCD-

ADJ)

3-2) ADF white level adjustment (COPIER > FUNCTION > CCD > DF-

WLVL1/2)

Be sure to perform white plate data adjustment before performing ADF

white level plate.

14.3.3 Adjusting the Position of the No. 1/No. 2 Mirror

Base

0015-9941

iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N

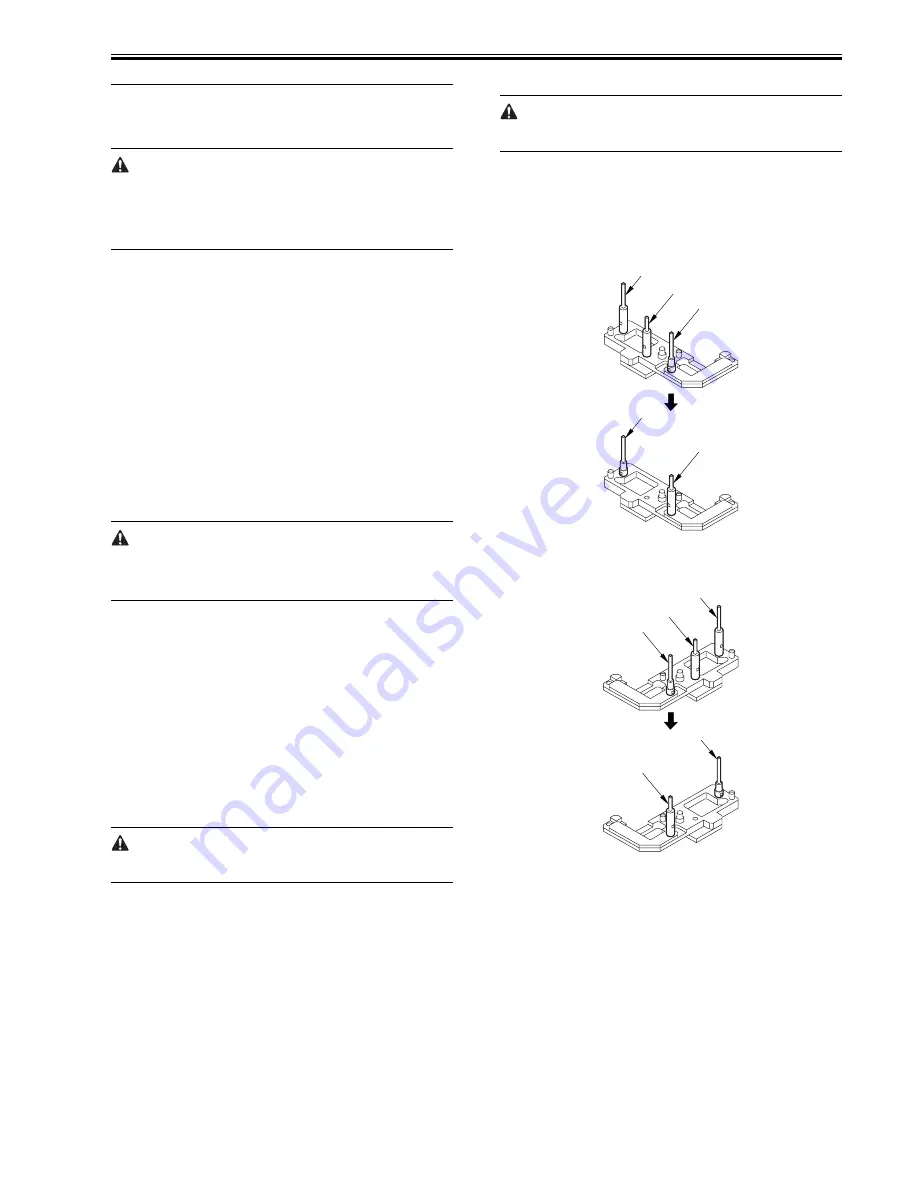

1) Arrange the mirror positioning tool (FY9-3009-040) so that it is ready for

use in the machine (by changing the pin position; REAR).

F-14-33

2) Arrange the mirror positioning tool so that it is ready for use in the ma-

chine (by changing the pin position; FRONT).

F-14-34

3) Fit the pins of the mirror positioning tool (front [2]; rear [3]) into the ap-

propriate holes [1] of the No. 1/No. 2 mirror base.

[A]

[B]

[C]

[B]

[A]

[A]

[B]

[C]

[B]

[A]

Summary of Contents for iR5055

Page 1: ...Feb 29 2008 Service Manual iR5075 5065 5055 Series ...

Page 2: ......

Page 6: ......

Page 27: ...Contents 19 1 2 List of Solvents Oils 19 2 ...

Page 28: ...Contents ...

Page 29: ...Chapter 1 Introduction ...

Page 30: ......

Page 32: ......

Page 59: ...Chapter 2 Installation ...

Page 60: ......

Page 104: ...Chapter 2 2 42 F 2 156 2 1 ...

Page 105: ...Chapter 3 Basic Operation ...

Page 106: ......

Page 108: ......

Page 115: ...Chapter 4 Main Controller ...

Page 116: ......

Page 118: ......

Page 135: ...Chapter 5 Original Exposure System ...

Page 136: ......

Page 169: ...Chapter 6 Laser Exposure ...

Page 170: ......

Page 172: ......

Page 178: ......

Page 179: ...Chapter 7 Image Formation ...

Page 180: ......

Page 184: ......

Page 217: ...Chapter 8 Pickup Feeding System ...

Page 218: ......

Page 274: ......

Page 275: ...Chapter 9 Fixing System ...

Page 276: ......

Page 280: ......

Page 320: ......

Page 321: ...Chapter 10 External and Controls ...

Page 322: ......

Page 326: ......

Page 336: ...Chapter 10 10 10 F 10 7 2 Remove the check mark from SNMP Status Enabled ...

Page 337: ...Chapter 10 10 11 F 10 8 ...

Page 361: ...Chapter 11 MEAP ...

Page 362: ......

Page 364: ......

Page 409: ...Chapter 12 e maintenance imageWARE Remote ...

Page 410: ......

Page 412: ......

Page 421: ...Chapter 13 Maintenance and Inspection ...

Page 422: ......

Page 424: ......

Page 433: ...Chapter 14 Standards and Adjustments ...

Page 434: ......

Page 464: ......

Page 465: ...Chapter 15 Correcting Faulty Images ...

Page 466: ......

Page 468: ......

Page 496: ......

Page 497: ...Chapter 16 Self Diagnosis ...

Page 498: ......

Page 500: ......

Page 528: ......

Page 529: ...Chapter 17 Service Mode ...

Page 530: ......

Page 532: ......

Page 600: ......

Page 601: ...Chapter 18 Upgrading ...

Page 602: ......

Page 604: ......

Page 636: ...Chapter 18 18 32 F 18 59 2 Select the data to download F 18 60 3 Click Start ...

Page 638: ......

Page 639: ...Chapter 19 Service Tools ...

Page 640: ......

Page 642: ......

Page 645: ...Feb 29 2008 ...

Page 646: ......