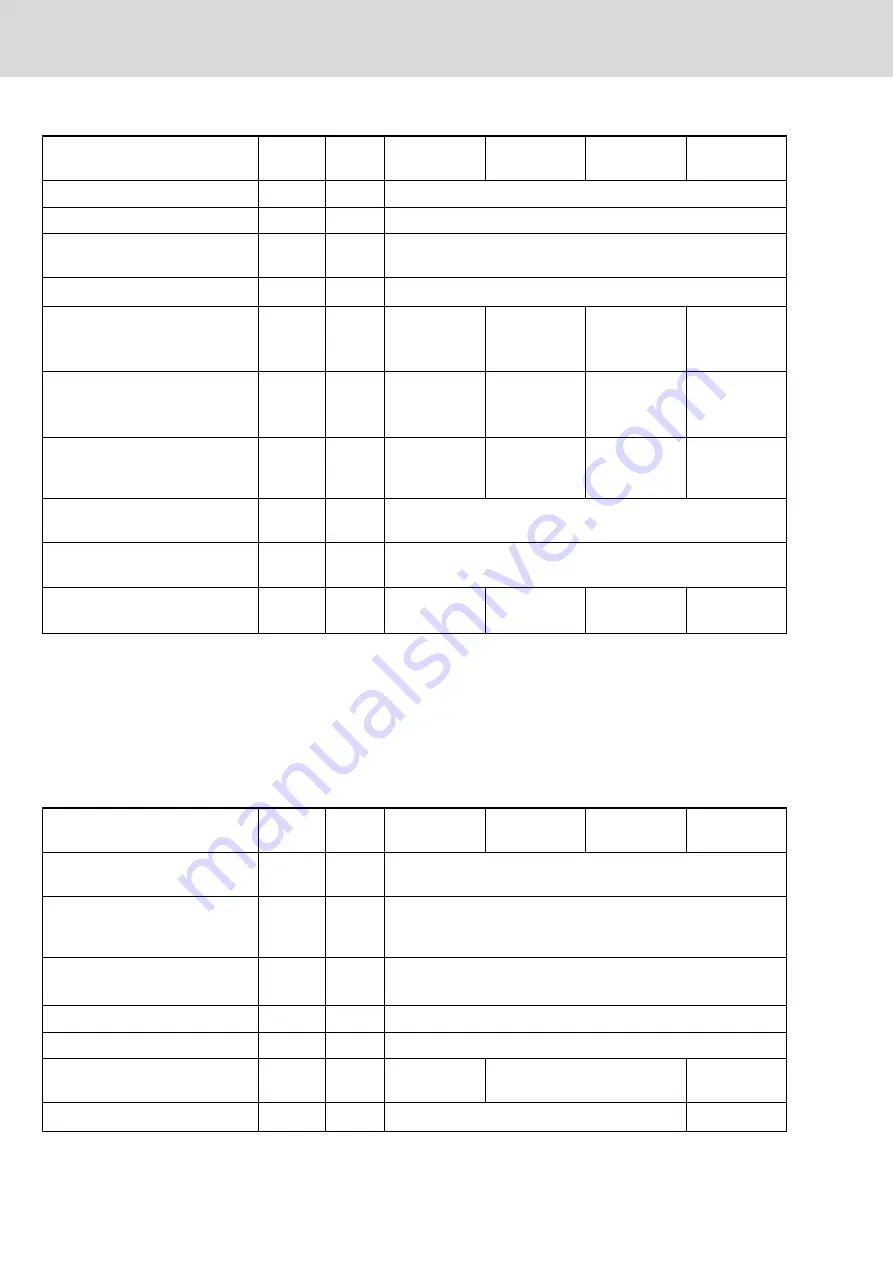

Description

Symbol

Unit

HMS01.1N-

W0020

HMS01.1N-

W0036

HMS01.1N-

W0054

HMS01.1N-

W0070

allowed mounting position

G1

cooling type

forced ventilation

volumetric capacity of forced cool‐

ing

V

m

3

/h

tbd

allowed switching frequencies

1)

f

s

kHz

4, 8, 12, 16

power dissipation at I

out_cont

= 0 A;

f

s

= f

s

(min.)

2)

P

Diss_0A_fsmi

n

W

60

40

90

110

power dissipation at I

out_cont

= 0 A;

f

s

= f

s

(max.)

3)

P

Diss_0A_fsma

x

W

120

130

260

330

power dissipation at continuous

current and continuous DC bus

power respectively (UL)

4)

P

Diss_cont

W

165,00

210,00

420,00

485,00

minimum distance on the top of the

device

5)

d

top

mm

80

minimum distance on the bottom of

the device

6)

d

bot

mm

100

temperature rise with minimum dis‐

tances d

bot

; d

top

; P

BD

ΔT

K

40

50

40

50

1)

also depending on firmware and control section; see Parameter De‐

scription "P‑0‑0001, Switching frequency of the power output stage"; see

"P-0-4058, Amplifier type data"

2) 3)

plus dissipation of braking resistor (at HMV, HCS) and control section

(at HMx, HCS); find interim values by interpolation to P_Diss_cont

4)

HMV, HCS: plus dissipation of braking resistor, control section; KSM:

plus rated power consumption control voltage input

5) 6)

see fig. "Air intake and air outlet at drive controller"

Fig.6-21:

HMS - Data for cooling and power dissipation

Data for cooling and power dissipation

Description

Symbol

Unit

HMS01.1N-

W0110

HMS01.1N-

W0150

HMS01.1N-

W0210

HMS01.1N-

W0350

ambient temperature range during

operation with nominal data

T

a_work

°C

0...40

ambient temperature range during

operation with reduced nominal da‐

ta

T

a_work_red

°C

0...55

derating of P

DC_cont

; P

BD

; I

out_cont

at

T

a_work

< T

a

< T

a_work_red

f

Ta

%/K

2,0

allowed mounting position

G1

cooling type

forced ventilation

volumetric capacity of forced cool‐

ing

V

m

3

/h

165,00

tbd

1400,00

allowed switching frequencies

1)

f

s

kHz

4, 8, 12, 16

4, 8, 12

114/369 Bosch Rexroth AG | Electric Drives

and Controls

Rexroth IndraDrive | Project Planning Manual

Power Sections for Inverters - IndraDrive M

Summary of Contents for Rexroth lndraDrive HCS02 Series

Page 10: ...Bosch Rexroth AG Electric Drives and Controls Rexroth IndraDrive Project Planning Manual ...

Page 14: ...Bosch Rexroth AG Electric Drives and Controls Rexroth IndraDrive Project Planning Manual ...

Page 36: ...Bosch Rexroth AG Electric Drives and Controls Rexroth IndraDrive Project Planning Manual ...

Page 108: ...Bosch Rexroth AG Electric Drives and Controls Rexroth IndraDrive Project Planning Manual ...

Page 300: ...Bosch Rexroth AG Electric Drives and Controls Rexroth IndraDrive Project Planning Manual ...

Page 312: ...Bosch Rexroth AG Electric Drives and Controls Rexroth IndraDrive Project Planning Manual ...

Page 372: ...Bosch Rexroth AG Electric Drives and Controls Rexroth IndraDrive Project Planning Manual ...

Page 380: ...Bosch Rexroth AG Electric Drives and Controls Rexroth IndraDrive Project Planning Manual ...