MAKING A SAMPLE

Section 5-2

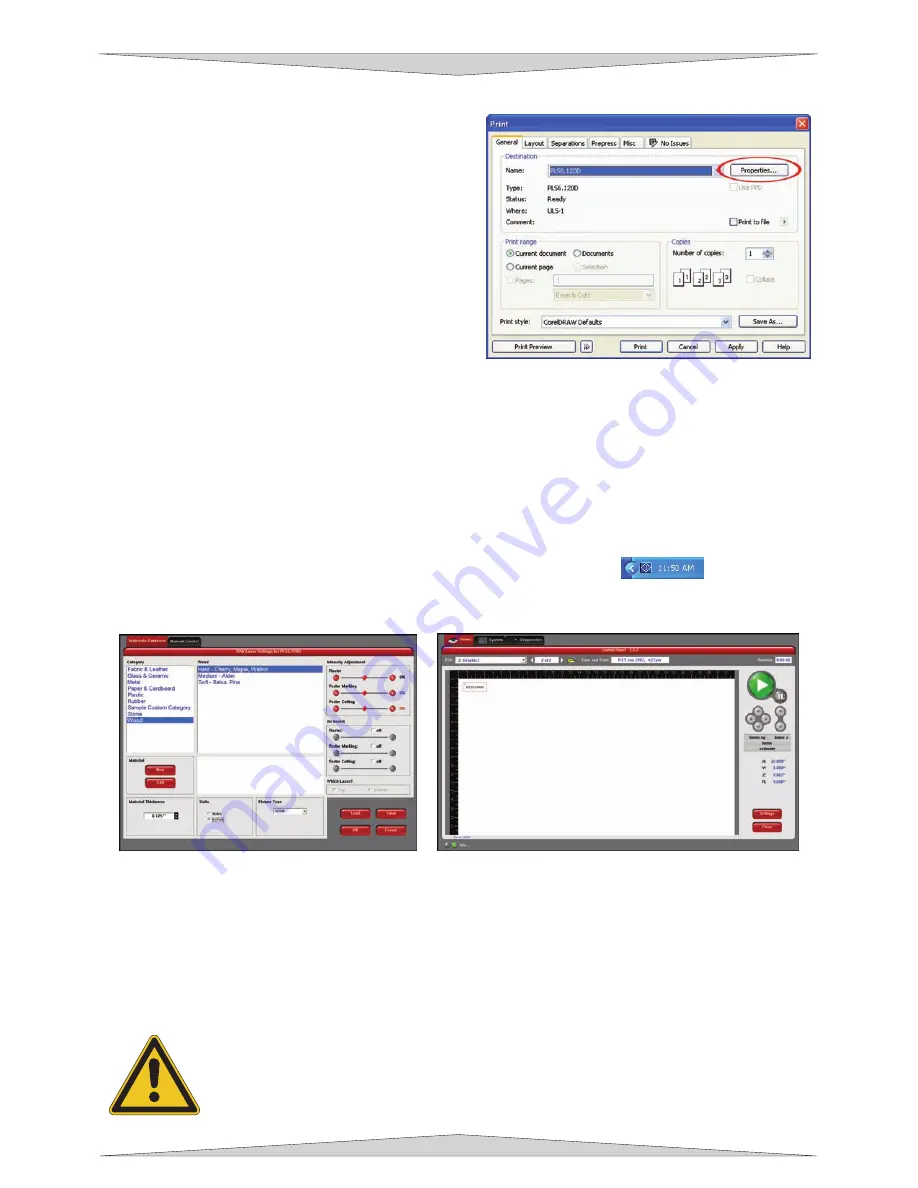

Step 3 – Printing to the Laser System (Materials Database Tab)

The following steps assume that CorelDraw X3 is

being used as your graphics software and using the

Materials Database Tab in the printer driver. Other

graphic software programs may differ.

When you are ready to print the file to the laser

system, click FILE and then click PRINT. Make sure

that the laser system appears in the DESTINATION

NAME dropdown list, and then click PROPERTIES

(Figure 4) to display the PLS printer driver settings

(Figure 5).

Choose your material by selecting the appropriate

category from the material categories on the left (in

this case wood) and then select the correct material

type from the material types on the right (in this case

hardwood) (Figure 5). Since we are placing the

material directly on the work surface, leave the Fixture Type set to NONE. If you were using an optional

accessory or custom fixture you would choose it from the fixture list. Using a calipers or similar

measuring device, enter the thickness of the material (in this case .125 inch). For this sample there is no

need to make changes to the INTENSITY ADJUSTMENT or AIR ASSIST boxes. If you have purchased

two laser tubes and would like to make your sample using both laser tubes select BOTH in the “Which

Laser?” box (PLS6.120D only). When you have made all the appropriate selections and entered the

material thickness, click OK. The printer driver closes and reverts back to the Print Dialog box and now

click on PRINT (Figure 4). As the print job is being created, a small printer icon will appear in your taskbar

in the lower right corner of your computer screen. Once the icon disappears the print job is completed

and is now stored on your hard drive. Click on the PLS icon in the taskbar

and the current

print job will appear in the Viewer Tab of the Universal Control Panel (Figure 6). Now click on the System

Tab and verify that the Auto Z box is checked. Return to the Viewer Tab and proceed to the next step.

Step 4 – Starting the Engraving Process

•

Turn ON the exhaust system and PLS machine. Laser tube fans will stop spinning once the laser

system has been turned on. This is normal and the fans will start spinning once engraving has

started.

•

Make sure the material is positioned correctly within the engraving area.

•

Make sure the top door is closed.

•

Click the green START button on the UCP to begin laser processing (Figure 6).

WARNING:

Observe that the laser system is functioning as desired. If any abnormalities

are present, including but not limited to, flaming, sparking, melting, or excessive smoking

of the material you are engraving,

STOP THE ENGRAVING PROCESS IMMEDIATELY

BY EITHER PRESSING THE PAUSE BUTTON OR OPENING THE TOP DOOR!

Re-

check the settings in the printer driver as well as the laser system. If everything seems to

Figure 5

Figure 6

Figure 4

Содержание PLS3.60

Страница 8: ......

Страница 20: ...SAFETY Section 1 12 ...

Страница 21: ...Part 1 Initial Setup ...

Страница 22: ......

Страница 30: ...INSTALLATION Section 2 10 ...

Страница 44: ...GRAPHICS SOFTWARE SETUP Section 3 14 ...

Страница 58: ...MAKING A SAMPLE Section 5 4 ...

Страница 59: ...Part 2 Laser System Essentials ...

Страница 60: ......

Страница 70: ...BASIC SYSTEM FEATURES Section 6 12 ...

Страница 76: ...BASIC MAINTENANCE Section 7 6 ...

Страница 77: ...Part 3 Accessories ...

Страница 78: ......

Страница 95: ...Part 4 Advanced User ...

Страница 96: ......

Страница 116: ...ADVANCED SYSTEM OPERATION Section 9 22 ...