ADVANCED SYSTEM OPERATION

Section 9-10

...will give you these results

Normal Rubber Stamp Setting

.002”

STEP WIDTH

STEP POWER %

0

8

20

31

39

49

59

10

0

Material

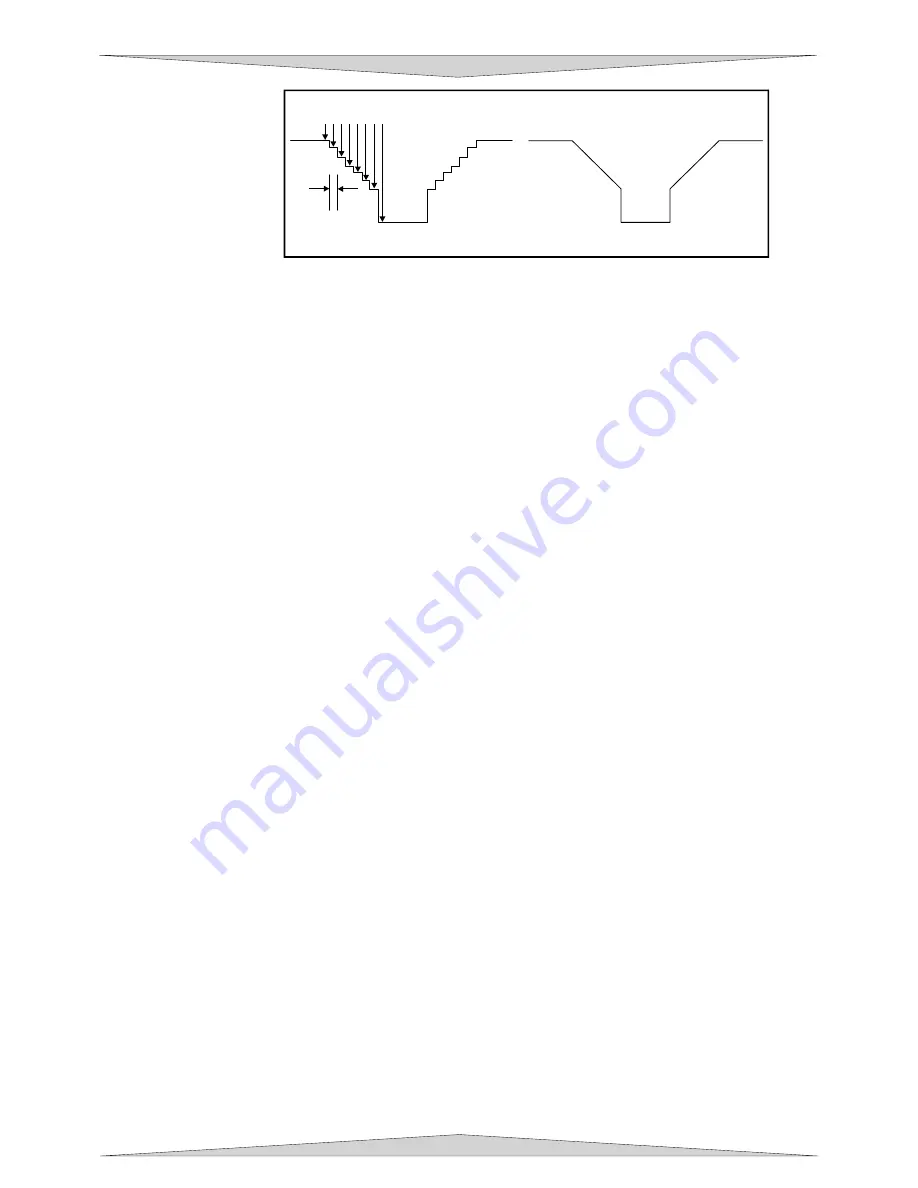

The diagram above is an example of the Normal Rubber Stamp Taper Selection.

You can see that there are 8 steps used to create the shoulder. The surface of the

material is considered the first step and the bottom of the engraving is considered the

last step. You can define as many as 16 steps but the first or the last steps are not

definable because they are fixed at a power setting of 0% and 100% respectively.

You can only define the parameters for the steps in between the first and last steps in

which there are 14 of them. By adjusting the power setting for each step, the width in

(.001) inches for each step, and the number of steps, different shoulder profiles can

be created.

NOTE:

The maximum shoulder width is .056 inches.

Image Density

This setting determines how many raster strokes per vertical inch of travel the motion system

steps down to produce the engraving. It can also be referred to as the vertical lines per inch or fill

spacing. In the Windows XP driver it is termed Image Density and there are 6 Image Density

choices in all models. Higher Image Density (DPI) settings produce better quality raster images,

but reduce productivity by increasing engraving time. Lower Image Density (DPI) settings

produce lower quality raster images, but increase productivity by decreasing engraving time.

Image Density (DPI) settings will also have an effect on vector quality and vector speeds when

vectoring other than straight horizontal or vertical lines. For example, a circle is made up of very

small straight-line segments linked together at very small angles. If you choose a high quality

setting such as 6 (1000 DPI), then these segments are as small as possible and they are high in

quantity. The result is the smoothest looking circle but will take longer to vector engrave or cut

because the focus carriage must start and stop at the ends of each line segment. Since there are

many segments, it will take longer to process, but the quality will be the highest that the machine

can produce. If using a low quality setting such as 1 (DRAFT), these segments become longer,

but there are less of them resulting in more flat-edged looking curves that will process faster.

By running samples on scrap materials and practicing with different settings, you can find a

compromise between throughput and engraving quality.

Print Direction

Your choices are Down or Up. The default direction is Down which begins engraving at the top of

the field and finishes at the bottom. On some materials you may get better results by starting at

the bottom and engraving towards the top of the field (Up). This is because the engraving smoke

is being drawn towards the top of the field. On some materials engraving Down causes the

smoke or debris from the engraving to be deposited onto the previously engraved surface,

possibly damaging the engraved area. Experiment with the different directions using different

materials and choose the best method for your application.

NOTE:

The Up direction is especially useful when engraving rubber stamps and utilizing the Back

Sweep Air Assist option.

Dithering

Dithering settings are used when printing grayscale or color bitmapped images such as TIF, JPG,

and BMP formatted images. Since the laser system is essentially a black and white printer (black

turns the laser ON and white turns the laser OFF), and if you choose the correct settings, the

driver will automatically convert the grayscale or color bitmap into a 1-bit “halftoned” black and

white image. This process is very similar to how newspaper photographs as well as laser printer

Содержание PLS3.60

Страница 8: ......

Страница 20: ...SAFETY Section 1 12 ...

Страница 21: ...Part 1 Initial Setup ...

Страница 22: ......

Страница 30: ...INSTALLATION Section 2 10 ...

Страница 44: ...GRAPHICS SOFTWARE SETUP Section 3 14 ...

Страница 58: ...MAKING A SAMPLE Section 5 4 ...

Страница 59: ...Part 2 Laser System Essentials ...

Страница 60: ......

Страница 70: ...BASIC SYSTEM FEATURES Section 6 12 ...

Страница 76: ...BASIC MAINTENANCE Section 7 6 ...

Страница 77: ...Part 3 Accessories ...

Страница 78: ......

Страница 95: ...Part 4 Advanced User ...

Страница 96: ......

Страница 116: ...ADVANCED SYSTEM OPERATION Section 9 22 ...