Function Blocks

UM353-1B

April

2012

3-54

P

ro c e s s

O P E R A T O R D IS P L A Y fo r C O N T R O L L E R S

P F

P

u ls e o f

F

O D C

P

S

V

U 1

S

e tp o in t

V

a lv e

U

s e r S ta tu s

2

P

u ls e o

N

IN P U T X

(H )

.........................

lo o p ta g .b lo c k tag .o u tp u t (n u ll)

U 2

IN P U T V

(H )

.........................

lo o p ta g .b lo c k ta g.o u tp u t (n u ll)

IN P U T S

(H )

..........................

lo o p ta g .b lo c k ta g .o u tp u t ( n u ll)

IN P U T P

(H )

.........................

lo o p ta g .b lo c k ta g.o u tp u t (n u ll)

IN P U T Y

(H )

.........................

lo o p ta g .b lo c k ta g.o u tp u t (n u ll)

X

V a ria b le

X

Y

L E

L

o o p

E

v e n t

P N

P

ro c e ss

- R

a n

G

e

P

o in

T

e

R

(S )

.........

lo o p ta g .b lo c k ta g (n u ll)

U

s e r

1

S T A T U S

(S )

......................... 8 C h a r. A S C II

(U 1 S T A T )

U

s e r

2

S T A T U S

(S )

......................... 8 C h a r. A S C II

(U 2 S T A T )

H

o r.

B A R

A C

tio n

(S )

.................................. R e v /D ir

(D ir)

IN P U T U 1

(H )

.......................

lo o p ta g .b lo c k ta g .o u tp u t (n u ll)

IN P U T U 2

(H )

.......................

lo o p ta g .b lo c k ta g .o u tp u t (n u ll)

V a ria b le

Y

U

s e r S ta tu s

1

P

G

R

U 1 S T A T U S

P T R

G

R

P T R

V

V

a lv e

- R

a n

G

e

P

o in

T

e

R

(S )

.............

lo o p ta g .b lo c k ta g (n u ll)

S

U

T

A

T

S

2

U

U 1

2

U

P R I O R

P R I O R

U

s e r

2

P R IO R

ity

(S )

.............................. 0 ,1 ,2 ,3 ,4 ,5

(5 )

U

s e r 1

P R IO R

ity

(S )

.............................. 0 ,1 ,2 ,3 ,4 ,5

(5 )

H

B A R

A C

I N P U T

I

I

I

I

N

N

N

N

P

P

P

P

U

U

U

U

T

T

T

T

P

S

V

Y

X

I

I

N

N

P

P

U

U

T

T

2

1

U

U

X

G

R

P T R

Y

G

R

P T R

In p u t

X

- R

a n

G

e

P

o in

T

e

R

(S )

..........

lo o p ta g .b lo c k ta g (n u ll)

In p u t

Y

- R

a n

G

e

P

o in

T

e

R

(S )

..........

lo o p ta g .b lo c k ta g (n u ll)

O P E R A T O R

D IS P L A Y

H

H

B A R

L D

B A R

R D

H

o r.

B A R L

e ft

D

is p la y

(S )

................. 5 C h a r A S C II

(C L O S E )

H

o r.

B A R R

ig h t

D

is p la y

(S )

............... 5 C h a r A S C II

(O P E N )

fo r

C O N T R O L L E R S

C M

C

o

M

p u te r

C

o

N

s o le

C N

N L

N

o t

L

o c a l

L

o c a l

O

p e ra tio n

L O

W D

W

a tc h

D

o g

C

o n s o le /

L

o c a l

C L

E

m e rg .

L

o c a l

E L

N E T W O R K

IN T E R F A C E

I N P U T

L

C

I N P U T

L

E

IN P U T C L

(H )

.......................

lo o p ta g .b lo c k ta g .o u tp u t (n u ll)

IN P U T E L

(H )

.......................

lo o p ta g .b lo c k ta g .o u tp u t (n u ll)

L

O P

#

L O O P #

(S )

................................................ 0 1 to 2 5

(n u ll)

V R

V

a lv e

R

a n g e

P

ro c e s s

R

a n g e

P R

X R

X R

a n g e

Y R

Y R

a n g e

O D

W

I E

V

V IE W

O

p e ra to r

D

is p la y

(H )

........................ N O /Y E S Y E S

S E

S

ta tio n

E

rro r

O

V

N E T

A C

V

a lv e B a r

N E T

w o rk

A C

tio n

(S )

.................. R e v /D ir

(D ir)

I

n p u t

A

A

G lo b a l

A la rm

M a n a g e m e n t

I N P U T

A

IN P U T A

(H )

......................

G lo b a l a la rm a c k n o w le d g e (n u ll)

R e v . 5

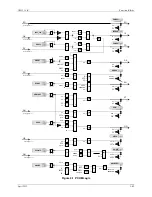

3.2.55 ODC - Operator Display for Controllers

ODC

blocks are one of five operator displays that are used

on a one per loop basis to configure the local operator

display functions and network parameters from a remote

operator workstation associated with the loop. See the i|ware

PC faceplate on the next page.

1.

Parameter VIEW OD, when set to YES, the default

setting, enables the operator display to be viewed and

accessed locally using the LOOP button. In some cases,

it may be desired to view only display or operation

parameters with a network workstation and not allow

operation or viewing of the control loop from the local

display. Here the parameter should be set to NO.

2.

Output LE is high (1) when a loop event is active.

Output SE is high when a station error is active.

3.

LOOP # is used to index reads and writes to Modbus

parameters. The LOOP# must be entered to enable

Modbus and Modbus/TCP communications.

Range pointers for both the process/setpoint and valve

bargraphs must be configured to define the range of the

variable inputs to P, S, and V. If these parameters are not

configured, the bargraphs will be scaled using the

engineering range of 0.00 to 100.00. The range pointer for

X and Y define the displayed decimal point position and the

units code. This information also defines the scaling of the

loop information provided to a remote workstation over the

network.

Input variables P, S, V, X, and Y are shown in the numeric display, using the engineering UNITS and the preferred

DPP of the range pointer. The Total from the BATOT will also be displayed when configured within the BATOT

block. If a value is greater than allowed by the DPP parameter, the decimal point will be shifted to allow the display

to show the full number, until it exceeds the maximum available digits, at which time it will indicate over range.

When input U1 or U2 goes high (1), the 8-character user status (U_STATUS) will be displayed as configured by the

status priority (U_ PRIOR). A priority of 0 will disable that status function setting the bits in the status word to 0.

See Section 8 Local Faceplate Operation for a description of display actions using priorities 1 to 5.

The horizontal bargraph can be selected as direct or reverse acting. This feature allows it to always indicate an

OPEN valve when fully lit. The labels on the basic faceplate are fixed, but paste on labels can be used to change the

indications. The V NET AC parameter allows the LxVI network parameter to be set for direct or reverse action.

This enables the valve bar on the HMI to operate similar to the valve bar on the faceplate. The left and right bar

labels should be set accordingly (e.g. Left = “OPEN & Right” = “CLOSE”).

An operator display must be configured to map controller loop data to network data. Loop network data is mapped

into registers or coils. Mappings for Modbus are listed in the tables included in Section 5 Network

Communications. The ‘LOOP #’ parameter enables configuration of a loop index number (x) for Modbus data.

Input CL controls local arbitration of changes to loop data from the network. When input CL is not configured, the

three status outputs LO, CN, and CM will be set high (1) and changes can be made from a network command or the

local faceplate. When CL is configured, it can be changed locally from a pushbutton switch such as PB1SW output

PS (configured as momentary) and will change from local to console or console/computer to local with each

positive transition of the input. Also, when output LO goes high, output CN will also go high and CM will go low,

indicating that the control source will change to Console whenever Local is disabled, either by a positive transition

Содержание 353

Страница 12: ...Contents UM353 1B x April 2012 ...

Страница 22: ...Introduction UM353 1B April 2012 1 10 ...

Страница 30: ...Configuration Overview UM353 1B April 2012 2 8 ...

Страница 122: ...Function Blocks UM353 1B April 2012 3 92 ...

Страница 168: ...Data Mapping UM353 1B April 2012 6 28 ...

Страница 204: ...Controller and System Test UM353 1B April 2012 9 8 ...

Страница 222: ...Calibration UM353 1B April 2012 11 4 ...

Страница 226: ...Circuit Description UM353 1B April 2012 12 4 ...

Страница 238: ...Model Designation and Specifications UM353 1B April 2012 13 12 EC Declaration of Conformity ...

Страница 239: ...UM353 1B Model Designation and Specifications April 2012 13 13 Annex A to the EC Declaration of Conformity ...

Страница 240: ...Model Designation and Specifications UM353 1B April 2012 13 14 ...

Страница 244: ...Abbreviations And Acronyms UM353 1B 14 4 April 2012 ...