Operation

UM353-1B

April

2012

8-4

8.3 AUTOTUNE PROCEDURE

If the AUTOTUNE parameter in the controller function block is set to YES, the autotune procedure can be initiated

using the TUNE pushbutton located behind the flip-down door. The Autotuner will substitute an ON_OFF

controller for the PD or PID function. By /- step changes to the valve position, the controller will control

the process at the current setpoint while it learns about the process dynamics. The controller then uses this

knowledge to derive recommended P, I, and, D settings.

Press the TUNE button to step through the following parameters and, if desired, initiate autotune:

PG

.....................

P

roportional Gain setting - (view or change)

TI

......................

I

ntegral Time setting - PID/PIDAG controllers only (view or change)

MR

.................... Manual Reset setting - PD controller only (view or change)

TD

.....................

D

erivative Time setting - (view or change)

% DEV

............. The peak/peak % process deviation that the autotuner will maintain during test

% HYS

.............. The % process change needed before the valve output will switch

AUTOTUNE

.... Set to YES and STORE to start autotune.

Press EXIT CONF to return to normal operator faceplate operation.

AT PG

...............

P

roportional Gain setting recommended by the autotuner

AT TI

................

I

ntegral Time setting recommended by the autotuner

AT TD

...............

D

erivative Time setting recommended by the autotuner

STORE AT

....... Pressing STORE transfers autotuner recommended settings to controller

While autotuning, the controller will continue normal operation. Pressing the A/M button to switch the controller to

Manual will terminate autotune. While in autotune, the alphanumeric display will alternate between ‘AUTOTUNE’

and the loop tag name and will stop alternating when the autotune program has been completed. Once completed,

the controller will return to the mode prior to autotune initiation. When the POST AT (in the controller block) is set

to auto transfer, the recommended tuning parameters will automatically be transferred to the controller and it will

return to automatic control. To review the AT parameters before initiating autotune, press TUNE and then press

STORE at the STORE AT prompt to transfer the recommended settings.

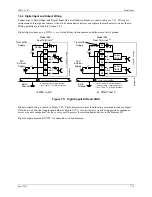

Chart 1 (0-100% range) illustrates a typical autotune exercise. The process has a small amount of noise

(approximately 1% P-P). The autotuner was set with fast response, the %HYS was set to A, and the %Dev was set

to A. The autotuner provided recommended settings of P=1.84 and I=0.38. These settings were entered into the

controller and a step change was made to the setpoint to review the response with the new controller settings.

The autotuner will use the initial valve step size (set as % STEP in the controller function block) during the first 1-

1/2

cycles to learn the approximate gain of the process. It will then adjust the valve step size during the remainder of

the autotuning exercise to maintain the % DEV setting. When this test concludes, the recommended settings are

transferred to the controller and a 20% setpoint change is made to illustrate the controller tuning.

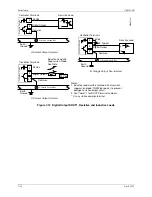

When the autotuner is started for the next autotune exercise, it will use the process gain learned during the previous

exercise to determine the valve step size unless: the parameter AT RESET in the controller block has been stored as

YES, warnings occurred during the first test, or the station has been power cycled.

Содержание 353

Страница 12: ...Contents UM353 1B x April 2012 ...

Страница 22: ...Introduction UM353 1B April 2012 1 10 ...

Страница 30: ...Configuration Overview UM353 1B April 2012 2 8 ...

Страница 122: ...Function Blocks UM353 1B April 2012 3 92 ...

Страница 168: ...Data Mapping UM353 1B April 2012 6 28 ...

Страница 204: ...Controller and System Test UM353 1B April 2012 9 8 ...

Страница 222: ...Calibration UM353 1B April 2012 11 4 ...

Страница 226: ...Circuit Description UM353 1B April 2012 12 4 ...

Страница 238: ...Model Designation and Specifications UM353 1B April 2012 13 12 EC Declaration of Conformity ...

Страница 239: ...UM353 1B Model Designation and Specifications April 2012 13 13 Annex A to the EC Declaration of Conformity ...

Страница 240: ...Model Designation and Specifications UM353 1B April 2012 13 14 ...

Страница 244: ...Abbreviations And Acronyms UM353 1B 14 4 April 2012 ...