METHOD FOR REPLACING HYDRAULIC OIL FILTER ELEMENT

k

k

WARNING

• Immediately after the engine is stopped, its parts and oil are still very hot and may cause burn in-

jury. Wait for the temperature to go down, and then start the work.

• When removing the oil filler cap, the oil may spurt out. Turn it slowly to release the internal pres-

sure, then remove it carefully.

Items to be prepared

Container to catch the drained oil

1.

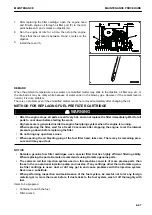

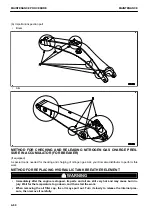

Park the machine on a level and firm ground, lower the

work equipment to the ground in the posture shown in the

figure, and stop the engine.

2.

Remove the cap of hydraulic tank oil filler port (F), and re-

lease the internal pressure.

3.

Loosen the bolts (4 pieces) and remove the cover (1).

The cover may be jumped out by spring (2). While pressing down the cover, remove the bolts.

REMARK

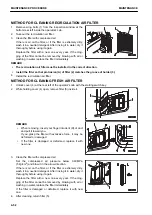

If the cover (1) is left approximately 5 minutes with the

mounting bolts loosened, the internal pressure of the case

is released and the oil in the element is drained, and ac-

cordingly less oil drips when the element is removed.

4.

After removing the spring (2), valve (3) and strainer (5),

take out the element (4).

If there is excessive metal powder or foreign material in

the strainer (5), contact your Komatsu distributor.

5.

Check the bottom of the filter case for dirt or other materi-

al, and remove any if found.

Take extreme care that the dirt does not fall into the hydraulic tank.

6.

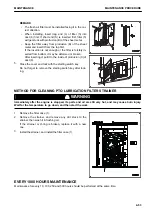

Clean the removed parts by using the flushing oil.

7.

Install the new element in the place where old element (4) was installed.

8.

Place the strainer (5), valve (3) and spring (2) onto the element.

9.

Set the cover (1) in position, press it down by hand, and install the cover with the mounting bolts.

10. Install the oil filler cap (F).

MAINTENANCE PROCEDURE

MAINTENANCE

4-54

Содержание PC700LC-11

Страница 2: ......

Страница 23: ...LOCATION OF SAFETY LABELS 5 SAFETY SAFETY LABELS 2 3...

Страница 66: ......

Страница 67: ...OPERATION Please read and make sure that you understand the SAFETY section before reading this section 3 1...

Страница 73: ...REMARK The above figure does not show all of the caution lamp symbols OPERATION GENERAL VIEW 3 7...

Страница 316: ......

Страница 317: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1...

Страница 331: ...Fuel main fil ter cartridge Replace Replace Replace Replace MAINTENANCE MAINTENANCE SCHEDULE 4 15...

Страница 375: ...A Important inspection part F Front Revolving frame Center frame MAINTENANCE MAINTENANCE PROCEDURE 4 59...

Страница 396: ......

Страница 397: ...SPECIFICATIONS 5 1...

Страница 401: ...For 7 6m Boom SPECIFICATIONS SPECIFICATIONS 5 5...

Страница 402: ...SPECIFICATIONS SPECIFICATIONS 5 6...

Страница 426: ......

Страница 427: ...REPLACEMENT PARTS 7 1...

Страница 434: ......

Страница 442: ...PC700LC 11 HYDRAULIC EXCAVATOR Form No UENAM01321 2017 KOMATSU All Rights Reserved Printed in Belgium 09 2017...