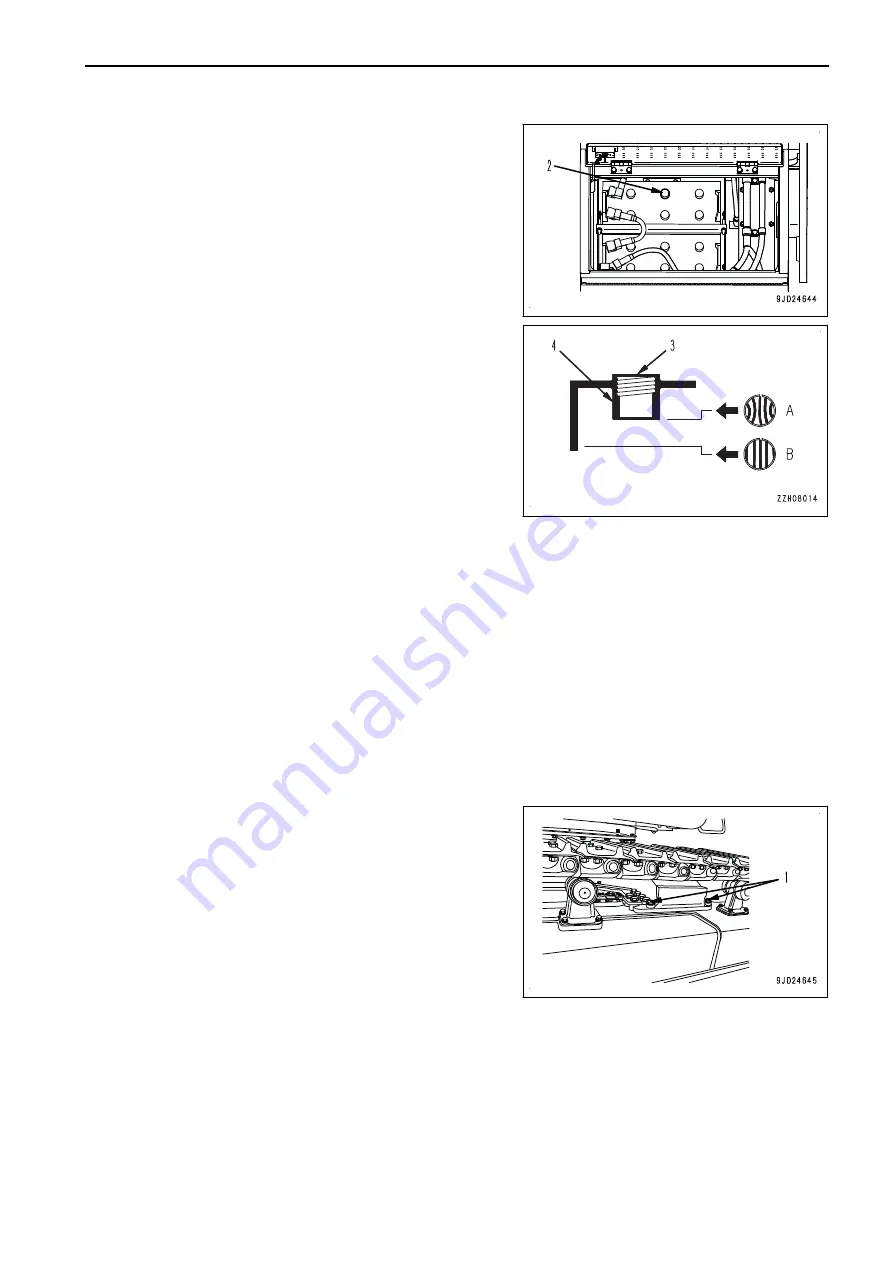

1.

Remove the cap (2) at the top of the battery and check the

electrolyte level through electrolyte filler port (3).

If the electrolyte does not reach the sleeve (4), always add

the purified water (such as a commercial battery fluid) so

that the level reaches the bottom of the sleeve (UPPER

LEVEL line).

• (A) Correct level: Electrolyte level is up to bottom of

sleeve, so surface tension causes electrolyte surface

to bulge and pole plate appears to be warped.

• (B) Low level: Electrolyte level does not reach the bot-

tom of sleeve, so pole plate appears straight and not

to be warped.

2.

After adding it, tighten the cap (2) securely.

REMARK

If it is added to above the bottom tip of the sleeve, use a syringe to remove it. Neutralize the removed fluid

with baking soda (sodium bicarbonate), then flush it away with a large amount of water. If necessary, con-

sult your Komatsu distributor or a battery manufacturer.

METHOD FOR CHECKING ELECTROLYTE LEVEL ON INDICATOR ETC

If it is possible to use an indicator to check the electrolyte level, follow the instructions given.

METHOD FOR CHECKING LOOSENESS AND TIGHTENING TRACK FRAME AND

CENTRE FRAME CONNECTING BOLTS

NOTICE

If the machine is used while the bolts which connect the centre frame and track frame are loose, the

bolts will break. If any looseness of connecting bolt is found, retighten it.

1.

Check for looseness of the bolts (1) connecting the centre

frame and track frame.

2.

If any looseness of the bolt is found, tighten it.

Tightening torque: 1960 to 2450 Nm {200 to 250 kgm}

EVERY 500 HOURS MAINTENANCE

Maintenance for every 10, 100 and 250 hours should be performed at the same time.

MAINTENANCE

MAINTENANCE PROCEDURE

4-45

Содержание PC700LC-11

Страница 2: ......

Страница 23: ...LOCATION OF SAFETY LABELS 5 SAFETY SAFETY LABELS 2 3...

Страница 66: ......

Страница 67: ...OPERATION Please read and make sure that you understand the SAFETY section before reading this section 3 1...

Страница 73: ...REMARK The above figure does not show all of the caution lamp symbols OPERATION GENERAL VIEW 3 7...

Страница 316: ......

Страница 317: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1...

Страница 331: ...Fuel main fil ter cartridge Replace Replace Replace Replace MAINTENANCE MAINTENANCE SCHEDULE 4 15...

Страница 375: ...A Important inspection part F Front Revolving frame Center frame MAINTENANCE MAINTENANCE PROCEDURE 4 59...

Страница 396: ......

Страница 397: ...SPECIFICATIONS 5 1...

Страница 401: ...For 7 6m Boom SPECIFICATIONS SPECIFICATIONS 5 5...

Страница 402: ...SPECIFICATIONS SPECIFICATIONS 5 6...

Страница 426: ......

Страница 427: ...REPLACEMENT PARTS 7 1...

Страница 434: ......

Страница 442: ...PC700LC 11 HYDRAULIC EXCAVATOR Form No UENAM01321 2017 KOMATSU All Rights Reserved Printed in Belgium 09 2017...