(5) Boom and arm connection pin (1 place)

(6) Bucket cylinder foot pin (1 place)

(7) Arm cylinder rod pin (1 place)

(8) Arm and link connection pin (1 place)

(9) Arm and bucket connection pin (1 place)

(10) Link connection pin (2 places)

(11) Bucket cylinder rod pin (1 place)

(12) Bucket and link connection pin (1 place)

EVERY 100 HOURS MAINTENANCE

Maintenance for every 10 hours service should be performed at the same time.

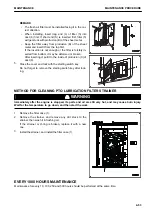

METHOD FOR LUBRICATING SWING CIRCLE

Items to be prepared

Grease pump

MAINTENANCE PROCEDURE

MAINTENANCE

4-42

Содержание PC700LC-11

Страница 2: ......

Страница 23: ...LOCATION OF SAFETY LABELS 5 SAFETY SAFETY LABELS 2 3...

Страница 66: ......

Страница 67: ...OPERATION Please read and make sure that you understand the SAFETY section before reading this section 3 1...

Страница 73: ...REMARK The above figure does not show all of the caution lamp symbols OPERATION GENERAL VIEW 3 7...

Страница 316: ......

Страница 317: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1...

Страница 331: ...Fuel main fil ter cartridge Replace Replace Replace Replace MAINTENANCE MAINTENANCE SCHEDULE 4 15...

Страница 375: ...A Important inspection part F Front Revolving frame Center frame MAINTENANCE MAINTENANCE PROCEDURE 4 59...

Страница 396: ......

Страница 397: ...SPECIFICATIONS 5 1...

Страница 401: ...For 7 6m Boom SPECIFICATIONS SPECIFICATIONS 5 5...

Страница 402: ...SPECIFICATIONS SPECIFICATIONS 5 6...

Страница 426: ......

Страница 427: ...REPLACEMENT PARTS 7 1...

Страница 434: ......

Страница 442: ...PC700LC 11 HYDRAULIC EXCAVATOR Form No UENAM01321 2017 KOMATSU All Rights Reserved Printed in Belgium 09 2017...