For details, see “METHOD FOR INSTALLING HYDRAULIC OIL FILLER PORT CAP”.

11. Start the engine and run it at low idle for 10 minutes to bleed air.

12. Stop the engine.

REMARK

Leave the machine as it is for at least 5 minutes, and then start the operation. This will remove the air bub-

bles in the oil inside the tank.

13. Check that there is no leakage of oil and wipe off any oil that is spilled.

METHOD FOR CHANGE OIL IN SWING MACHINERY CASE

k

k

WARNING

Immediately after the engine is stopped, its parts and oil are still very hot, and may cause burn injury.

Wait for the temperature to go down, and then start the work.

Refill capacity: 26 ℓ (13 ℓ each of right and left)

Items to be prepared

Container to catch the fuel

1.

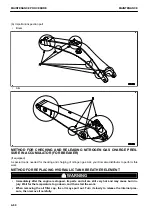

Install the hose (1) which is stored in the toolbox to the

drain valve (P) at the bottom of the machine and place a

container to catch the oil under the hose.

2.

Loosen the drain valve (P) at the bottom of the machine,

drain the oil, then tighten the drain valve again.

3.

Replace the breather (2) at the same time as the oil is

changed.

4.

Add the refill capacity of oil through the pipe for dipstick

(G).

5.

Wipe off the oil from the dipstick with a cloth.

6.

Fully insert the dipstick (G) into the dipstick pipe, then pull

it out.

7.

The oil level should be between the (H) and (L) marks on

the dipstick (G).

If the oil level is below the (L) mark, add oil through the oil

filler port (F).

8.

If the oil level is above (H) mark, drain the excessive oil

through the drain plug (P) on the lower part of the ma-

chine, and then check the oil level again.

9.

The oil level may not be stabilized immediately after the re-

placement. Operate the machine for an hour, then check

the oil level again.

MAINTENANCE

MAINTENANCE PROCEDURE

4-55

Содержание PC700LC-11

Страница 2: ......

Страница 23: ...LOCATION OF SAFETY LABELS 5 SAFETY SAFETY LABELS 2 3...

Страница 66: ......

Страница 67: ...OPERATION Please read and make sure that you understand the SAFETY section before reading this section 3 1...

Страница 73: ...REMARK The above figure does not show all of the caution lamp symbols OPERATION GENERAL VIEW 3 7...

Страница 316: ......

Страница 317: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1...

Страница 331: ...Fuel main fil ter cartridge Replace Replace Replace Replace MAINTENANCE MAINTENANCE SCHEDULE 4 15...

Страница 375: ...A Important inspection part F Front Revolving frame Center frame MAINTENANCE MAINTENANCE PROCEDURE 4 59...

Страница 396: ......

Страница 397: ...SPECIFICATIONS 5 1...

Страница 401: ...For 7 6m Boom SPECIFICATIONS SPECIFICATIONS 5 5...

Страница 402: ...SPECIFICATIONS SPECIFICATIONS 5 6...

Страница 426: ......

Страница 427: ...REPLACEMENT PARTS 7 1...

Страница 434: ......

Страница 442: ...PC700LC 11 HYDRAULIC EXCAVATOR Form No UENAM01321 2017 KOMATSU All Rights Reserved Printed in Belgium 09 2017...