1.

Set the TOP mark at the top to make the TOP mark and

plug (P) are positioned as shown in the right figure.

2.

Remove the plug (F) by using the handle.

When the oil level is within the range of 10 mm below the

lower edge of the plug hole, the oil level is appropriate.

If the oil level is low, check it again according to the follow-

ing procedure.

1) Install the plug (F).

2) Operate the travel lever to move the machine forward

or reverse and rotate the sprocket by 1 turn.

3) Check in the procedure of the step 2.

3.

If the oil is insufficient, add oil through the plug (F) hole.

Add oil until oil overflows from the hole of plug (F).

4.

After the inspection, install the plug (F).

Tightening torque of plug (F): 93.1 to 122.5 Nm {9.5 to

12.5 kgm}

METHOD FOR CHECKING BATTERY ELECTROLYTE LEVEL

Perform this procedure before operating the machine.

k

k

WARNING

Do not use the battery if the battery electrolyte level is below LOWER LEVEL line. If you do so, it will

deteriorate the battery inside and reduce the service life of the battery. In addition, it may cause an ex-

plosion.

Do not bring any open flame near the battery. Otherwise, it may explode since the battery generates the

flammable gas.

Battery electrolyte is dangerous object. If it gets in your eyes or on your skin, wash it off with a large

amount of water and consult a doctor.

NOTICE

Do not add the electrolyte to the battery exceeding UPPER LEVEL line. If the electrolyte level is too

high, it may leak and cause damage to the paint surface or corrode other parts.

If the battery water may freeze after refilling with the purified water (such as a commercial battery fluid),

do the replenishment before the day's work on the next day.

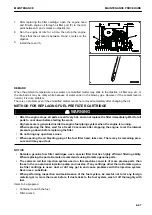

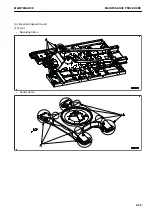

Open the cover (1) at the right front of the machine and you

find the battery. The battery is installed at (A) part.

Inspect the battery electrolyte level at least once a month ac-

cording to the following procedure.

KS000580

MAINTENANCE PROCEDURE

MAINTENANCE

4-44

Содержание PC700LC-11

Страница 2: ......

Страница 23: ...LOCATION OF SAFETY LABELS 5 SAFETY SAFETY LABELS 2 3...

Страница 66: ......

Страница 67: ...OPERATION Please read and make sure that you understand the SAFETY section before reading this section 3 1...

Страница 73: ...REMARK The above figure does not show all of the caution lamp symbols OPERATION GENERAL VIEW 3 7...

Страница 316: ......

Страница 317: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1...

Страница 331: ...Fuel main fil ter cartridge Replace Replace Replace Replace MAINTENANCE MAINTENANCE SCHEDULE 4 15...

Страница 375: ...A Important inspection part F Front Revolving frame Center frame MAINTENANCE MAINTENANCE PROCEDURE 4 59...

Страница 396: ......

Страница 397: ...SPECIFICATIONS 5 1...

Страница 401: ...For 7 6m Boom SPECIFICATIONS SPECIFICATIONS 5 5...

Страница 402: ...SPECIFICATIONS SPECIFICATIONS 5 6...

Страница 426: ......

Страница 427: ...REPLACEMENT PARTS 7 1...

Страница 434: ......

Страница 442: ...PC700LC 11 HYDRAULIC EXCAVATOR Form No UENAM01321 2017 KOMATSU All Rights Reserved Printed in Belgium 09 2017...