Check level of refrigerant (gas)

k

k

WARNING

If the refrigerant used in the air conditioner gets into your eyes or is splashed on your hands, it may

cause loss of sight or frostbite. Never touch the refrigerant. Do not loosen any part of the refrigerant

circuit.

Do not bring any open flame close to any point where the refrigerant gas is leaking.

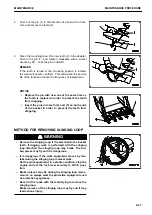

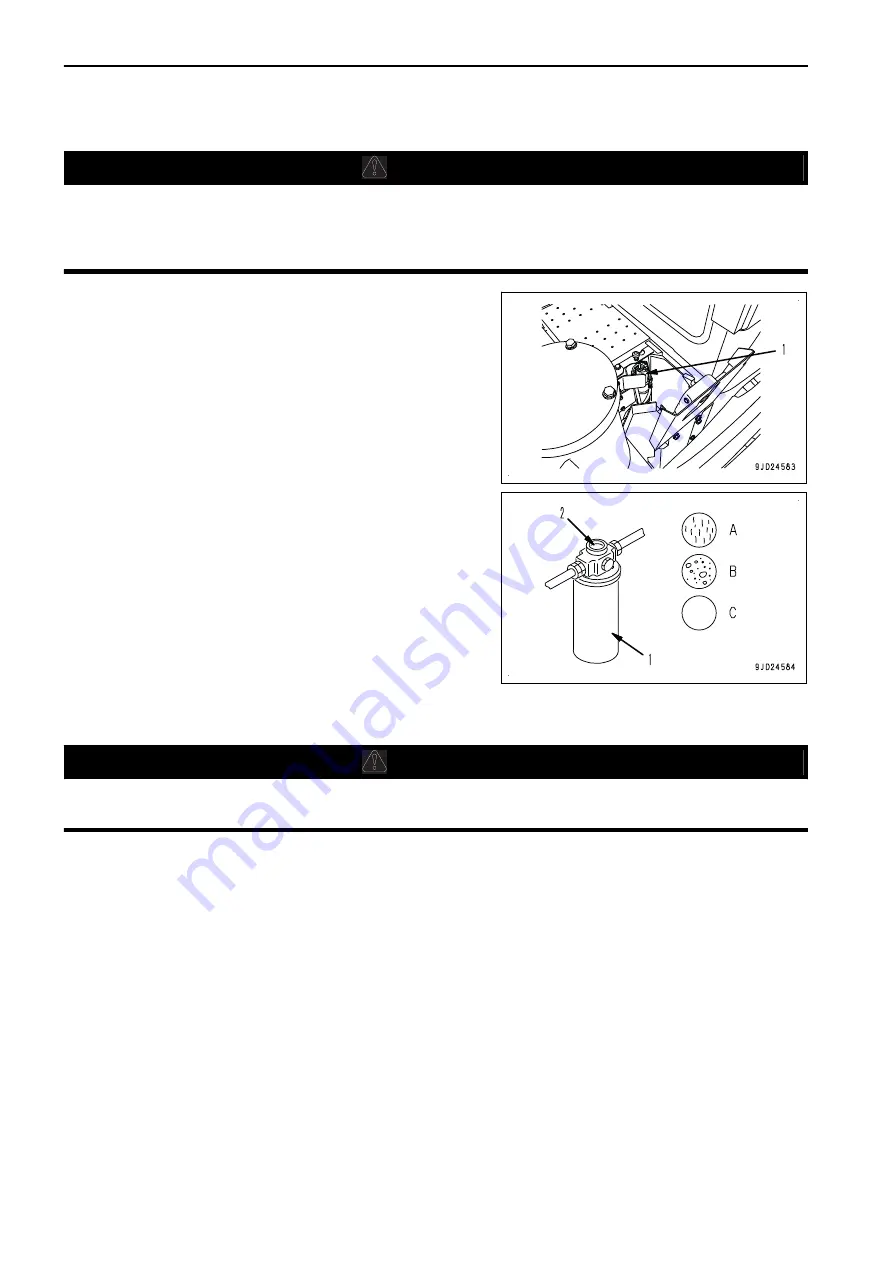

If the level of the refrigerant (gas) is low, the cooling effect will

be reduced. Run the engine at high idle, and check the flow of

the refrigerant gas (Hydrofluorocarbons HFC -134a) in the re-

frigerant circuit through the sight glass (2) (inspection window)

of the receiver (1) when the cooler is running at high speed.

(A) No bubbles in refrigerant flow: Suitable

(B) Some bubbles in refrigerant flow (bubbles pass continuous-

ly): Insufficient

(C) Colorless, transparent: No refrigerant

REMARK

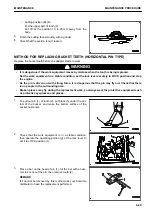

When there are bubbles, the refrigerant gas level is low. Con-

tact your Komatsu distributor to have refrigerant added. If the

air conditioner is operated with the refrigerant gas level low, it

will cause damage to the compressor.

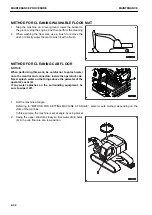

METHOD FOR REPLACING ADDITIONAL FILTER ELEMENT FOR BREAKER

(if equipped)

k

k

WARNING

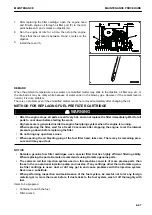

• Immediately after the engine is stopped, its parts and oil are still very hot, and may cause burn in-

jury. Wait for the temperature to go down, and then start the work.

For the element replacement interval, see “MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER”.

Items to be prepared

Container to catch the oil

1.

Place a container to catch the drained oil under the filter element.

MAINTENANCE PROCEDURE

MAINTENANCE

4-32

Содержание PC700LC-11

Страница 2: ......

Страница 23: ...LOCATION OF SAFETY LABELS 5 SAFETY SAFETY LABELS 2 3...

Страница 66: ......

Страница 67: ...OPERATION Please read and make sure that you understand the SAFETY section before reading this section 3 1...

Страница 73: ...REMARK The above figure does not show all of the caution lamp symbols OPERATION GENERAL VIEW 3 7...

Страница 316: ......

Страница 317: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1...

Страница 331: ...Fuel main fil ter cartridge Replace Replace Replace Replace MAINTENANCE MAINTENANCE SCHEDULE 4 15...

Страница 375: ...A Important inspection part F Front Revolving frame Center frame MAINTENANCE MAINTENANCE PROCEDURE 4 59...

Страница 396: ......

Страница 397: ...SPECIFICATIONS 5 1...

Страница 401: ...For 7 6m Boom SPECIFICATIONS SPECIFICATIONS 5 5...

Страница 402: ...SPECIFICATIONS SPECIFICATIONS 5 6...

Страница 426: ......

Страница 427: ...REPLACEMENT PARTS 7 1...

Страница 434: ......

Страница 442: ...PC700LC 11 HYDRAULIC EXCAVATOR Form No UENAM01321 2017 KOMATSU All Rights Reserved Printed in Belgium 09 2017...