ELECTRICAL

Page G-7

Repair and Service Manual

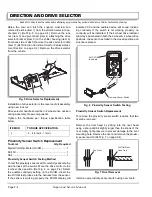

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings

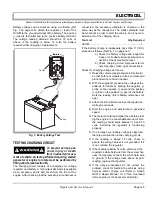

Check power wire

The white power wire supplies power to the

entire fuse block.

Firmly attach the black probe (-) to the battery post with

the black wire attached and the red probe (+) to the white

wire terminal at the fuse block. A reading of battery volt-

age indicates that the power wire is in good condition.

Check fuse

Check each fuse for continuity. If a new fuse is required,

replace with one of the same amperage.

ACCESSORY WIRING

After determining that there is power to the fuse panel,

and the fuse is good, continue checking the circuit using

the procedures previously used to check the power sup-

ply, i.e. loose or rusted connections, bare wires, continu-

ity of the wiring from terminal to terminal, operating

condition of switch, etc.

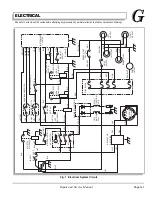

Use the wiring diagram (Ref Fig. 1 on page G-1) to check

correct wiring and wire routing. If there is power at the

fuse end of the wire, there must also be power at the

other end of the wire at the switch or electrical accessory,

and eventually at the ground connection. Electricity must

flow from the fuse panel through the full length of the cir-

cuit to the ground connection. Any interruption of electri-

cal flow must be corrected, whether by repairing or

replacing the wire, the switch or accessory.

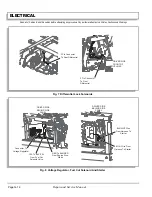

INSTRUMENT CLUSTER

The instrument cluster contains indicator lights for 4

Wheel Drive, Parking Brake, Fuel Gauge, Front and Rear

Differential Locks, Low Oil Pressure and a digital hour

meter. The cluster is not repairable and must be replaced

if there is a malfunction within the unit (Ref Fig. 4 on

page G-9).

The Four Wheel Drive Indicator is operated by a prox-

imity switch and the switch can be tested as described in

the ‘DIRECTION SELECTOR’ section of this manual.

The switch does not operate the four wheel drive, only

the indicator light. Similarly the Parking Brake Indicator

uses the same proximity switch that can be tested in the

same way. If the switch is good, check for voltage at the

instrument cluster connector. If voltage is present but the

indicator is not working, replace the instrument cluster. If

voltage is not present, verify that the switch is correctly

oriented in relation to the operating component and that

the wire harness does not have an internal break.

The Fuel Gauge Sending unit test is described in the

‘FUEL SYSTEM’. If the sending unit and the wiring from

the unit to the instrument cluster connector is satisfac-

tory, replace the instrument cluster (Ref Fig. 6 on page

G-11).

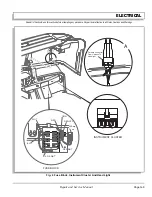

The Differential Lock indicator and switches can be

checked by operating them and observing the solenoids

at the differentials. If the solenoid operates but the indica-

tor does not, check for voltage at the instrument cluster

connector. If voltage is present but the indicator is not

working, replace the instrument cluster. If solenoids do

not function, verify that the switches have continuity

when closed and replace switch if continuity is not

present. If the switch functions correctly, and if battery

voltage is not present, check the fuse and that the wire

harness does not have an internal break.

Low Oil Pressure Gauge With the engine off, check for

continuity between the oil pressure switch’s two termi-

nals. Continuity should be indicated. If not replace the

switch. Check that there is adequate oil in the engine and

start engine. Shortly after starting, the continuity across

the oil pressure switch should be lost as the switch opens

in response to oil pressure. If not, replace the switch.

With the switch known to be good, the indicator light

should illuminate at the instrument cluster, when the key

switch is ON but the engine is not running. If not check

the gray wire at the instrument cluster for battery voltage.

If battery voltage is present, replace the instrument clus-

ter. If battery voltage is not present, check that wire har-

ness does not have an internal break.

DIFFERENTIAL LOCK SOLENOIDS

Check operation of switches as described in INSTRU-

MENT CLUSTER The Differential Lock (Ref Fig. 7 on

page G-12). With the switch in the engaged position,

check for voltage at the differential lock solenoid connec-

tor. If voltage is present, replace solenoid. If battery volt-

age is not present, check the fuse and that the wire

harness does not have an internal break. Replace sole-

noid.

Содержание ST 4X4

Страница 6: ...Page iv Repair and Service Manual TABLE OF CONTENTS Notes...

Страница 10: ...Repair and Service Manual SAFETY INFORMATION Page viii Notes...

Страница 12: ...GENERAL INFORMATION ROUTINE MAINTENANCE Page A ii Repair and Service Manual Notes...

Страница 24: ...SAFETY Page B ii Repair and Service Manual Notes...

Страница 34: ...BODY AND TRUCKBED Page C ii Repair and Service Manual Notes...

Страница 50: ...BRAKES Page D ii Repair and Service Manual Notes...

Страница 68: ...CONTINUOUSLY VARIABLE TRANSMISSION CVT Page E ii Repair and Service Manual Notes...

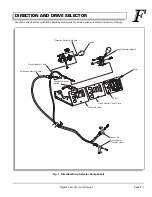

Страница 74: ...DIRECTION AND DRIVE SELECTOR Page F ii Repair and Service Manual Notes...

Страница 80: ...ELECTRICAL Page G ii Repair and Service Manual Notes...

Страница 114: ...FRONT SUSPENSION AND STEERING Page J ii Repair and Service Manual Notes...

Страница 128: ...FUEL SYSTEM Page K ii Repair and Service Manual Notes...

Страница 136: ...PAINT Page L ii Repair and Service Manual Notes...

Страница 142: ...REAR AXLE AND SUSPENSION Page M ii Repair and Service Manual Notes...

Страница 152: ...SPEED CONTROL Page N ii Repair and Service Manual Notes...

Страница 160: ...TROUBLESHOOTING Page P ii Repair and Service Manual Notes...

Страница 168: ...WHEELS AND TIRES Page R ii Repair and Service Manual Notes...

Страница 174: ...GENERAL SPECIFICATIONS Page S ii Repair and Service Manual Notes...

Страница 180: ...LIMITED WARRANTY Page T ii Repair and Service Manual Notes...

Страница 182: ...Page T 2 Repair and Service Manual LIMITED WARRANTY Notes...