BRAKES

Page D-12

Repair and Service Manual

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings

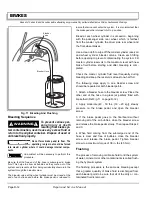

Bleeding Sequence

To prevent serious per-

sonal injury or death

resulting from brake sys-

tem contamination, never reuse any excess fluid or

return to the original container. Dispose of used or

old brake fluid properly.

Do not force brake pedal to floor. The

operating rod jam nut could be forced

into master cylinder where it could damage internal compo-

nents.

An assistant will be necessary to perform this

procedure.

Be sure that the free end of the hose is submerged in brake

fluid. This helps to show air bubbles as they come out of the

system, and prevents air from being accidentally drawn into the

system through the bleeder screw.

The bleeder valve at the wheel cylinder must be closed at the

end of each stroke and before the brake pedal is released to

insure that air cannot enter the system. It is also important that

the brake pedal be returned to full ‘up’ position.

Bleed at each wheel cylinder in succession, beginning

with the passenger side rear wheel, which is farthest

from the master cylinder, the driver side rear wheel and

the front wheel brakes.

Use a clean cloth to wipe off the master cylinder reservoir

and wheel cylinder bleeder valves. Clean each fitting

before opening to prevent contaminating the system. Fill

master cylinder reservoir to the maximum level with new

brake fluid before starting and after bleeding is com-

pleted.

Check the master cylinder fluid level frequently during

bleeding and keep the reservoirs at least one-half full.

The following steps apply to one bleeder screw and

should be repeated at both bleeder points.

1. Attach a bleeder hose to the bleeder screw. Place the

other end of the hose in a glass jar partially filled with

brake fluid (Ref Fig. 11 on page D-12).

2. Apply moderate (40 - 50 lbs. [18 – 20 kg]), steady

pressure on the brake pedal, and open the bleeder

screw.

3. If the brake pedal goes to the floorboard without

removing all of the air bubbles, close the bleeder screw

and release the brake pedal slowly. Then repeat Steps 2

and 3.

4. When fluid coming from the submerged end of the

hose is clear and free of bubbles, close the bleeder

screw and release the brake pedal. Tighten bleeder

screw to a maximum torque of 38 in. lbs (4.3 Nm).

Flushing

The process of removing old brake fluid to rid the system

of water, mineral oil or other contaminants is called flush-

ing the hydraulic system.

The flushing procedure is the same as bleeding except

that a greater quantity of brake fluid is discharged from

each bleeder point to be sure that all of the dirty or con-

taminated fluid is removed.

Fig. 11 Bleeding And Flushing

Bleeder Hose

Bleeder

Valve

!

!

Содержание ST 4X4

Страница 6: ...Page iv Repair and Service Manual TABLE OF CONTENTS Notes...

Страница 10: ...Repair and Service Manual SAFETY INFORMATION Page viii Notes...

Страница 12: ...GENERAL INFORMATION ROUTINE MAINTENANCE Page A ii Repair and Service Manual Notes...

Страница 24: ...SAFETY Page B ii Repair and Service Manual Notes...

Страница 34: ...BODY AND TRUCKBED Page C ii Repair and Service Manual Notes...

Страница 50: ...BRAKES Page D ii Repair and Service Manual Notes...

Страница 68: ...CONTINUOUSLY VARIABLE TRANSMISSION CVT Page E ii Repair and Service Manual Notes...

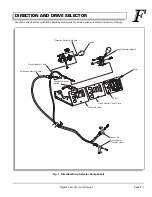

Страница 74: ...DIRECTION AND DRIVE SELECTOR Page F ii Repair and Service Manual Notes...

Страница 80: ...ELECTRICAL Page G ii Repair and Service Manual Notes...

Страница 114: ...FRONT SUSPENSION AND STEERING Page J ii Repair and Service Manual Notes...

Страница 128: ...FUEL SYSTEM Page K ii Repair and Service Manual Notes...

Страница 136: ...PAINT Page L ii Repair and Service Manual Notes...

Страница 142: ...REAR AXLE AND SUSPENSION Page M ii Repair and Service Manual Notes...

Страница 152: ...SPEED CONTROL Page N ii Repair and Service Manual Notes...

Страница 160: ...TROUBLESHOOTING Page P ii Repair and Service Manual Notes...

Страница 168: ...WHEELS AND TIRES Page R ii Repair and Service Manual Notes...

Страница 174: ...GENERAL SPECIFICATIONS Page S ii Repair and Service Manual Notes...

Страница 180: ...LIMITED WARRANTY Page T ii Repair and Service Manual Notes...

Страница 182: ...Page T 2 Repair and Service Manual LIMITED WARRANTY Notes...