138

factory if it is not possible to reduce the CO level below 200PPM air free within the range of CO2s shown for the fuel and

altitude at which the boiler is being used.

8) Replace the screw cap in the vent adapter when combustion testing is complete.

` " ) ## % % ' #&&' #

10) Verify that the gas inlet pressure is between the following shown in Table A.5 with all gas appliances (including the converted

boiler) both on and off.

11) LP CONVERSIONS ONLY - A sheet of yellow labels is provided in the envelope with this manual for boilers converted

from natural to LP gas. Select the model from this sheet of labels and apply them as follows:

a. Apply the “Rating Plate Label” adjacent to the rating plate.

b. Apply the “Gas Valve Label” to a conspicuous area on the gas valve.

c. Apply the “Boiler Conversion Label” to a conspicuous surface on, or adjacent to, the outer boiler jacket. Fill in the

date of the conversion and the name and address of the company making the conversion with a permanent marker.

12) Refer to the “Start-up and Checkout” section of the boiler installation manual and perform any checks not already completed.

13) Higher altitudes cause the boiler input and output to drop by between 0% and 2.4% per thousand feet, depending on model,

fuel, and altitude. Consult factory for details.

"&

0

!,()?!*"-:BB+)-! )(*

(()*(>-#A*B?$A+

:66%%.((,()*)+B-#A*

B?$:A(?!*"-;((,(

)*)+B@A*B$A*?

:66%%.(,()B(-

0

A(,()\I(F?J@*

*()*(6j+A? -$B*

)(BB)@B,(-')

)*(>( ??6j$:AI?A4666BB)J

$-)*(?BB*(BA,()-*

BB*B(@(?F?(C)

)*(-!@?((F?@(

)*(>AD($:*BY-

Содержание PHNTM080

Страница 2: ......

Страница 9: ...7 Figure 4 1 Minimum Clearances To Combustible Construction...

Страница 11: ...9 Figure 5 1 Wall Layout Mounting Hole Location...

Страница 12: ...10 Figure 5 2 Boiler Mounting Bracket Installation Boiler Wall Mounting...

Страница 39: ...37 FIGURE 7 24 SPLIT VENT SYSTEM FLEX IN ABANDONED MASONRY CHIMNEY VENT OPTIONS 33 38...

Страница 63: ...61 This page is intentionally left blank...

Страница 68: ...66 FIGURE 9 2 PIPING METHOD 1 NEAR BOILER PIPING HEATING ONLY...

Страница 69: ...67 FIGURE 9 3A PIPING METHOD 1 NEAR BOILER PIPING HEATING PLUS INDIRECT WATER HEATER IWH OFF PRIMARY LOOP...

Страница 70: ...68 FIGURE 9 3B PIPING METHOD 1 NEAR BOILER PIPING HEATING PLUS INDIRECT WATER HEATER IWH OFF BOILER LOOP...

Страница 72: ...70 FIGURE 9 6 PIPING METHOD 1 NEAR BOILER PIPING SHADED BOILER LOOP...

Страница 80: ...78 FIGURE 10 2 HIGH VOLTAGE PCB TERMINAL CONNECTIONS FIGURE 10 3 LOW VOLTAGE PCB TERMINAL CONNECTIONS...

Страница 82: ...80 FIGURE 10 4 PROPER INSTALLATION OF HEADER SENSOR...

Страница 84: ...82 FIGURE 10 6 INTERNAL WIRING CONNECTIONS DIAGRAM...

Страница 85: ...83...

Страница 92: ...90 Lighting and Operating Instructions...

Страница 98: ...96 FIGURE 12 2 PIPING FOR DHW OPTIONS 1 2 ALSO SEE FIGURES 9 3A 9 3B FIGURE 12 3 PIPING FOR DHW OPTION 3...

Страница 101: ...99 FIGURE 12 5 SETTINGS MENU SEE PART C FOR ADDITIONAL INFORMATION...

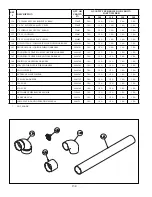

Страница 113: ...111 FIGURE 13 2 IGNITION ELECTRODE GAP FIGURE 13 3 CONDENSATE TRAP EXPLODED PARTS VIEW...

Страница 125: ...123...

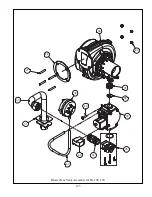

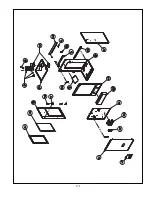

Страница 127: ...125 40 33 31 27 28 34 35 37 38 32 39 36 29 30 48 Blower Gas Valve Assembly for 80 100 120...

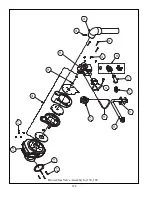

Страница 128: ...126 31 28 27 32 44 42 29 41 45 38 47 30 43 35 46 34 36 33 39 Blower Gas Valve Assembly for 150 180...

Страница 129: ...127...

Страница 131: ...129...

Страница 132: ...130...

Страница 133: ...131...

Страница 135: ...133...

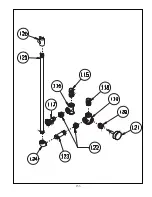

Страница 137: ...135 140 141 142 143 144 145...