107

1)

Continuously

:

a.

Keep the area around the boiler

free from combustible materials, gasoline and other

)& ( &

b.

Keep the area around the combustion air inlet terminal

free from contaminates.

c.

Keep the boiler room ventilation openings

open and unobstructed.

2)

Monthly Inspections

:

a.

Inspect the vent piping and outside air intake piping

to verify they are open, unobstructed and free

from leakage or deterioration. Call the service technician to make repairs if needed.

b.

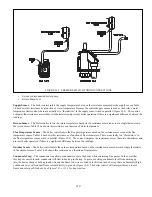

Inspect the condensate drain system

to verify it is leak tight, open and unobstructed. Call the service

technician if the condensate drain system requires maintenance.

c.

Inspect the water and gas lines

to verify they are free from leaks. Call the service technician to make

repairs

if

required.

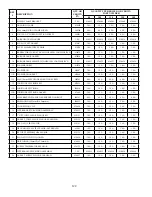

4)

Annual Inspections and Service

: In addition to the inspections listed above, the following should be performed by a

service technician once every year.

a.

Follow the procedure

for turning the boiler off found in the Lighting and Operating Instructions, on page 90.

b.

Turn off all power

to the boiler.

c.

Inspect the wiring

to verify the conductors are in good condition and attached securely.

d.

Verify that the gas shutoff

shown in Figure 8.1 is closed

e.

;<

#%)) _^ %`

f.

Unplug the electrical connection

to the gas valve.

g.

Disconnect the air proving switch tube

from the gas valve outlet tap.

h.

Unplug the power and speed control cables

from the blower.

$!

A*))(?BB)

AB -

$!

F(A)*))B-

))BF(-

"'!$<"!!!$

F>-#*?B?A-

()BB(B-BBBA-

"())v))@xD(>( Ax*-#

(y*B(A((*)z(-v(D(

vBBxD()(Fv)x-

"&

>-+B>-"?(*F(B?C?)F

*F?(49-6-((,

)AA-FBBF)

(*(A-

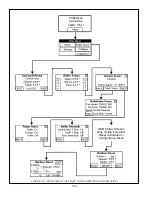

Содержание PHNTM080

Страница 2: ......

Страница 9: ...7 Figure 4 1 Minimum Clearances To Combustible Construction...

Страница 11: ...9 Figure 5 1 Wall Layout Mounting Hole Location...

Страница 12: ...10 Figure 5 2 Boiler Mounting Bracket Installation Boiler Wall Mounting...

Страница 39: ...37 FIGURE 7 24 SPLIT VENT SYSTEM FLEX IN ABANDONED MASONRY CHIMNEY VENT OPTIONS 33 38...

Страница 63: ...61 This page is intentionally left blank...

Страница 68: ...66 FIGURE 9 2 PIPING METHOD 1 NEAR BOILER PIPING HEATING ONLY...

Страница 69: ...67 FIGURE 9 3A PIPING METHOD 1 NEAR BOILER PIPING HEATING PLUS INDIRECT WATER HEATER IWH OFF PRIMARY LOOP...

Страница 70: ...68 FIGURE 9 3B PIPING METHOD 1 NEAR BOILER PIPING HEATING PLUS INDIRECT WATER HEATER IWH OFF BOILER LOOP...

Страница 72: ...70 FIGURE 9 6 PIPING METHOD 1 NEAR BOILER PIPING SHADED BOILER LOOP...

Страница 80: ...78 FIGURE 10 2 HIGH VOLTAGE PCB TERMINAL CONNECTIONS FIGURE 10 3 LOW VOLTAGE PCB TERMINAL CONNECTIONS...

Страница 82: ...80 FIGURE 10 4 PROPER INSTALLATION OF HEADER SENSOR...

Страница 84: ...82 FIGURE 10 6 INTERNAL WIRING CONNECTIONS DIAGRAM...

Страница 85: ...83...

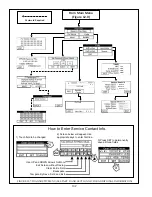

Страница 92: ...90 Lighting and Operating Instructions...

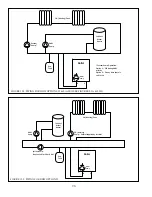

Страница 98: ...96 FIGURE 12 2 PIPING FOR DHW OPTIONS 1 2 ALSO SEE FIGURES 9 3A 9 3B FIGURE 12 3 PIPING FOR DHW OPTION 3...

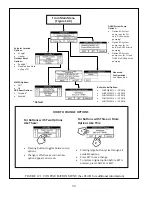

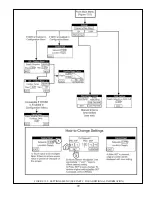

Страница 101: ...99 FIGURE 12 5 SETTINGS MENU SEE PART C FOR ADDITIONAL INFORMATION...

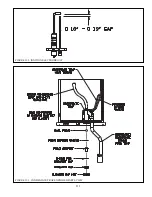

Страница 113: ...111 FIGURE 13 2 IGNITION ELECTRODE GAP FIGURE 13 3 CONDENSATE TRAP EXPLODED PARTS VIEW...

Страница 125: ...123...

Страница 127: ...125 40 33 31 27 28 34 35 37 38 32 39 36 29 30 48 Blower Gas Valve Assembly for 80 100 120...

Страница 128: ...126 31 28 27 32 44 42 29 41 45 38 47 30 43 35 46 34 36 33 39 Blower Gas Valve Assembly for 150 180...

Страница 129: ...127...

Страница 131: ...129...

Страница 132: ...130...

Страница 133: ...131...

Страница 135: ...133...

Страница 137: ...135 140 141 142 143 144 145...